High Quality JIS G3454(Carbon Steel Pipes For Pressure Service)Pressure Service

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20M.T. m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of High Quality JIS G3454(Carbon Steel Pipes For Pressure Service)Pressure Service

Standard:G3454

OD:10-650mm,WT:1-80mm

Length:5-12m random or be fixed as customers' request

JIS G3454 Carbon Steel Pipes for Pressure Service

1)Standard:JIS G3454

2)Material:STPG 370,STPG410

3)Size:OD.10-650mm,WT.1-80mm

Application of High Quality JIS G3454(Carbon Steel Pipes For Pressure Service)Pressure Service

Boiler, electricity, mechanical, gas cylinder, chemical, offshore and oil service

Surface Finishing of High Quality JIS G3454(Carbon Steel Pipes For Pressure Service)Pressure Service

Anti-corrosion and high-temperature resistant with black painting

Packing of High Quality JIS G3454(Carbon Steel Pipes For Pressure Service)Pressure Service

Bundles, seaworthy wooden cases.With or without end caps, varnish or as per clients requirements.

1. Scope of High Quality JIS G3454(Carbon Steel Pipes For Pressure Service)Pressure Service

This Japanese Industrial Standard specifies the carbon steel pipes, hereinafter referred to as the "pipes", used for pressure service at an approximate maximum temperature of

350°C. The pipes for high pressure service shall be in accordance with JIS G 3455.

1. Pertaining to the electric-resistance welded steel tubes, when previously agreed upon with the manufacturer, the purchaser may designate the supplementary quality

requirements Z 3 or Z 4 specified in Appendix, in addition to the items specified in this text.

Appendix Z 3 Ultrasonic Examination

Appendix Z 4 Eddy Current Examination

2. The units and numerical values given in { } in this Standard are based on the international System of Units (SI) and are appended for informative reference.

Further, the traditional units accompanied by numerical values in this Standard shall be converted to the SI units and numerical values on Jan. 1, 1991.

2. Grade and Designation of High Quality JIS G3454(Carbon Steel Pipes For Pressure Service)Pressure Service

The pipe shall be classified into two grades and their letter symbols shall be as given in Table 1-1 .

Letter symbol of grade |

Traditional letters symbol of glade |

STPG 370 |

STPG 38 |

STPG 410 |

STPG 42 |

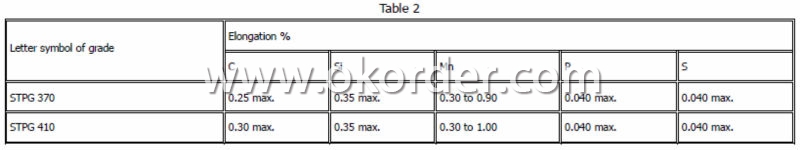

3.Chemical Composition of High Quality JIS G3454(Carbon Steel Pipes For Pressure Service)Pressure Service

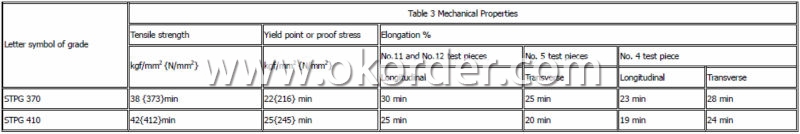

4.Mechanical Properties of High Quality JIS G3454(Carbon Steel Pipes For Pressure Service)Pressure Service

Tensile Strength,Yield Point or Proof Stress and Elongation

- Q: What is the maximum diameter of steel pipes?

- The maximum diameter of steel pipes can vary depending on various factors such as manufacturing capabilities, industry standards, and specific project requirements. However, steel pipes can typically range from a few millimeters in diameter for small-scale applications to several meters in diameter for large-scale industrial projects.

- Q: Can steel pipes be used for geothermal heating systems?

- Yes, steel pipes can be used for geothermal heating systems. Steel pipes are commonly used in the construction of geothermal systems due to their durability, high heat transfer capabilities, and resistance to corrosion. They are capable of withstanding the high temperatures and pressure associated with geothermal heating systems, making them an ideal choice for transporting and distributing the geothermal fluid.

- Q: What's the material of Q325 steel pipe?

- In terms of deoxidation methods, F, B, Z can be expressed as boiling steel, flat killed steel, killed steel and boiling steel. They are deoxidized steel, which is of poor plasticity and toughness. Welded joints made of this material are susceptible to cracks when subjected to dynamic loads. Should not work at low temperatures, sometimes hardening. In contrast, calming steel is excellent and uniform, with good plasticity and toughness.

- Q: What's the difference between a cracked carbon steel tube and a liquid carbon steel tube?

- If the material is the same, the process is different from the test.

- Q: Fastener type steel pipe scaffold external parts name

- Foot board can be made of steel, wood, bamboo and other materials, each quality should not be greater than 30kg. Stamping steel foot board is a kind of commonly used foot board, usually with thick 2mm steel plate pressing, length 2-4m, width 250mm, the surface should be anti-skid measures. Wooden feet can use the thickness of not less than 50mm fir wood or pine production, length 3~4m, width of 200-250mm, both ends should be galvanized steel band two, in order to prevent the wooden foot end of the destruction.

- Q: What is the average lifespan of steel pipes?

- The average lifespan of steel pipes varies depending on various factors such as their quality, usage, and maintenance. However, under normal conditions, well-maintained steel pipes can last for several decades or even longer.

- Q: How are steel pipes used in the construction of railways and transportation systems?

- Steel pipes are used in the construction of railways and transportation systems primarily for their durability and strength. They are utilized for various purposes such as the fabrication of tracks, bridges, tunnels, and support structures. Steel pipes provide a reliable and long-lasting solution for the transportation industry, ensuring the safety and efficiency of railway systems.

- Q: What are the different types of steel pipe fittings for gas pipelines?

- There are several types of steel pipe fittings commonly used for gas pipelines, including elbows, tees, reducers, couplings, and flanges. These fittings are essential for connecting and directing the flow of gas within the pipeline system.

- Q: How are steel pipes used in the construction of wind farms?

- Steel pipes are commonly used in the construction of wind farms to support and secure the wind turbines. These pipes serve as the foundation for the turbines, providing stability and structural integrity. They are used to create the tower structure, which supports the nacelle and rotor blades. Additionally, steel pipes are used for transporting and distributing the electrical cables within the wind farm, ensuring efficient transmission of electricity generated by the turbines.

- Q: How are steel pipes used in the construction of biomass power plants?

- Steel pipes are used in biomass power plants for various applications such as transporting biomass fuel, carrying water for steam generation, and distributing hot water or steam throughout the plant. They provide a sturdy and reliable infrastructure for the efficient functioning of the plant, ensuring the safe and effective operation of the biomass power generation process.

1. Manufacturer Overview

| Location | Wuxi, China |

| Year Established | 1991 |

| Annual Output Value | 300,000Tons |

| Main Markets | Europe; Southeast Asia; etc. |

| Company Certifications | API 5L;API 5CT;API Q1;ISO/TS29001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Wuxi; Shanghai |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 3900-4000 People |

| Language Spoken: | English; Chinese; Spanish |

| b) Factory Information | |

| Factory Size: | Above 450,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

High Quality JIS G3454(Carbon Steel Pipes For Pressure Service)Pressure Service

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20M.T. m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords