JIS G3303 Standard Tinplate, CA, T57 Temper

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Usage

Tinplate is widely used for making all types of containers, containing industrial usage such as paint can, oil can, aerosol cans etc., and food cans like milk powder cans, tomato paste can, dry food cans etc.

2. Quality

As a state owned company and a large tinplate supplier in China, our tinplate quality ranks 1st level in China, similar to Bao Steel, Posco etc.

3. Specification

standard: GB/T2520, JIS G3303, DIN EN10202

Material: MR /SPCC

Thickness available: 0.16-0.50MM

Width available: 600~1050MM

Temper grade: T1 – DR8

Tin coating: ordinary 2.8g/2.8g, 5.6g/5.6g and others

Package: sea worthy export package.

Applications: Tin can for chemicals & paint cans, industrial cans, food cans

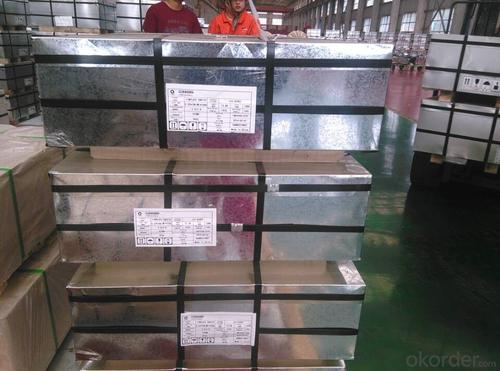

4. Our factory photo & equipments

5. Our Markets:

now our tinplate has been sold to more than 50 countries, including Europe country, Gulf Area, South American, South Afric etc.

6. Our Overseas Wareouses:

Furthermore, in the year 2014, we have more than 10 overseas warehouses all over the word, located in KSA, UAE, Oman, Russia, Kuwait, Qatar, Oman, Chile, Brazil etc.

7. FAQ

a. what's the annual output?

about 500,000 tons per year.

b. where's the raw matrial from?

our hot rolled coil is purchased from Capital Steel and other state owned mill, with quite good quality.

c. how long is the delivery time?

normally for SPCC about 45~55 days, while 65~75 days for MR material

d. how to control the quality during production process?

inside our workshop, we have MES syestem. It realizes the optimization of the production procedure in the workshop. It could record each step of the whole production procedures, and if some problem appears, factory could easily found and take action, it’s quite helpful to monitor and control the quality.

- Q: What are the main factors affecting tinplate coil surface finish?

- The main factors affecting tinplate coil surface finish include the quality of the tin coating, the cleanliness of the substrate, the condition of the rolling mill, the temperature and pressure during the rolling process, the presence of impurities or contaminants, and the effectiveness of post-processing treatments such as annealing or tempering.

- Q: How long does tinplate last?

- Tinplate can last for several decades or even longer with proper care and maintenance.

- Q: How is tinplate used in the construction industry?

- Tinplate is commonly used in the construction industry for various applications. It is often utilized for roofing materials, such as tinplate shingles or metal roof panels, due to its durability, weather resistance, and corrosion protection. Additionally, tinplate is used for cladding or siding purposes, providing an aesthetically pleasing and long-lasting exterior finish for buildings. Its versatility also extends to ductwork, where tinplate is used to fabricate air conditioning and ventilation systems. Overall, tinplate's strength, flexibility, and protective properties make it a valuable material in the construction sector.

- Q: What is the tensile strength of tinplate?

- The tensile strength of tinplate typically ranges from 30,000 to 50,000 pounds per square inch (psi).

- Q: What are the advantages of using tinplate for aerosol cans?

- Some advantages of using tinplate for aerosol cans include its durability, corrosion resistance, and ability to maintain product quality. Tinplate cans offer a longer shelf life for aerosol products as they prevent air and moisture from entering the can, ensuring the product remains fresh and effective. Additionally, tinplate cans are lightweight, making them convenient for transportation and storage. They are also recyclable, contributing to sustainability efforts.

- Q: What are the different testing methods for tinplate packaging?

- Some of the different testing methods for tinplate packaging include visual inspection, leak testing, drop testing, compression testing, and corrosion resistance testing.

- Q: What are the different types of tinplate finishes?

- There are several different types of tinplate finishes, including bright finish, stone finish, matte finish, and lacquered finish.

- Q: How is tinplate cleaned and maintained?

- Tinplate is commonly cleaned and maintained by wiping it with a damp cloth or sponge using mild soapy water to remove any dirt or stains. It is important to avoid using abrasive cleaners or scrubbing brushes as they can scratch the surface. To maintain its shine and prevent corrosion, it is recommended to dry the tinplate thoroughly after cleaning and store it in a dry place away from moisture. Additionally, applying a thin coat of oil or wax can help protect the tinplate from rusting.

- Q: How big is the difference between tinplate and stainless steel 316L?

- Tinplate, also known as tin plated iron, is the common name of tin plated steel sheet. It is a cold-rolled low carbon steel sheet or strip coated with commercially pure tin on both sides. Tin plays a major role in preventing corrosion and rusting.

- Q: Can tinplate be used for packaging beauty and skincare products?

- Yes, tinplate can be used for packaging beauty and skincare products. Tinplate is commonly used in the packaging industry due to its excellent durability, corrosion resistance, and ability to preserve the quality of the products. It also provides an attractive and professional appearance, making it suitable for beauty and skincare products that require an appealing presentation.

Send your message to us

JIS G3303 Standard Tinplate, CA, T57 Temper

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords