MR Tinplate JIS G3303 For Industrial Usage

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Usage

Tinplate is widely used for making all types of containers, containing industrial usage such as paint can, oil can, aerosol cans etc., and food cans like milk powder cans, tomato paste can, dry food cans etc.

2. Quality

As a state owned company and a large tinplate supplier in China, our tinplate quality ranks 1st level in China, similar to Bao Steel, Posco etc.

3. CA Line Production Range

Temper | Thickness(mm) | Width(mm) | Length(mm) |

T3CA | 0.19~0.20 | 800~900 | 520~1068 |

0.21~0.25 | 800~950 | ||

0.26~0.45 | 800~1050 | ||

T4CA | 0.17~0.20 | 800~950 | |

0.20~0.45 | 800~1050 | ||

T5CA | 0.17~0.20 | 800~950 | |

0.20~0.28 | 800~1050 |

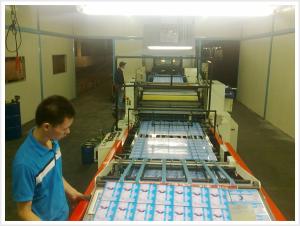

4. Our factory photo & equipments

6. FAQ

a. What’s the price difference between SPCC & MR?

Our MR is about usd 15~20/mt higher than SPCC; b. What’s the difference between SPCC & MR

They have difference element content, MR is better than SPCC in anti-rust and deep drawing.

Steel | C | Si | Mn | P | S | Cu | Others |

MR | ≤0.09 | ≤0.03 | ≤0.35 | ≤0.02 | ≤0.025 | ≤0.1 | ≤0.35 |

SPCC | ≤0.12 | ≤0.5 | ≤0.035 | ≤0.025 |

c. What production standards you accept?

We could accept production standards upon our customer request, such as JISG 3303, DIN EN10202, GB/T2520 etc. Our tinplate could meet these standards.

d. If we want to place order, is there any requirement about the booking time?

We need to purchase raw material in advance. Around date 20 per month our production plan will be finalized. So it’s better if customer could place order before date 20 per month, otherwise the delivery time will delay one month.

- Q: How does tinplate packaging contribute to product protection against leakage?

- Tinplate packaging contributes to product protection against leakage primarily due to its durable and corrosion-resistant properties. The tin coating on the steel substrate prevents any contact between the product and the surrounding environment, minimizing the risk of leakage. Additionally, tinplate packaging is often manufactured using advanced sealing techniques, ensuring airtight and leak-proof closures. Overall, the robust nature of tinplate packaging serves as a reliable barrier, safeguarding the product from potential leakage and preserving its quality.

- Q: How does tinplate contribute to the freshness of pet food?

- Tinplate contributes to the freshness of pet food by providing a protective barrier against oxygen, moisture, and light. This helps to prevent spoilage and maintain the quality of the food, ensuring it stays fresh for a longer period of time.

- Q: How does tinplate contribute to the safety and integrity of packaged products?

- Tinplate contributes to the safety and integrity of packaged products through its excellent protective properties. The tin coating on the steel substrate acts as a barrier, preventing direct contact between the packaged product and the metal surface. This barrier helps to prevent corrosion, oxidation, and contamination of the product. Additionally, tinplate offers high strength and durability, ensuring that the package remains intact during handling and transportation, thereby safeguarding the contents from potential damage or spoilage.

- Q: How does tinplate perform in microwave ovens?

- Tinplate should not be used in microwave ovens as it is a metal, and metals can cause sparks or damage to the appliance.

- Q: What are the main challenges in tinplate coating?

- The main challenges in tinplate coating include achieving consistent and uniform coating thickness, ensuring adhesion between the tin layer and the substrate, preventing corrosion and oxidation of the tin layer, and minimizing the formation of defects such as pinholes, blisters, and wrinkles. Additionally, challenges arise in maintaining the desired surface finish, controlling the tin coating composition, and improving the overall efficiency and cost-effectiveness of the coating process.

- Q: The difference between a matte tin plate and a bright tin plate

- Tin ma:Rough processing refers to electroplating in the original plate after passivation, not by tin matte soft melting process. It has a unique and elegant silver gray surface, and it has high adhesiveness after coating. It is used in bottle caps and printing cans.

- Q: How does tinplate perform in terms of moisture resistance?

- Tinplate performs exceptionally well in terms of moisture resistance. The tin coating on the surface acts as a protective barrier, preventing moisture from coming into contact with the underlying metal. This makes tinplate highly resistant to corrosion and oxidation caused by moisture, ensuring the product's durability and longevity.

- Q: Can tinplate packaging be used for pet food products?

- Yes, tinplate packaging can be used for pet food products.

- Q: How is tinplate coated for signage?

- Tinplate for signage is typically coated through a process known as electroplating, where a thin layer of metal, such as tin or chromium, is deposited onto the surface of the tinplate. This coating not only enhances the visual appeal of the signage but also provides protection against corrosion and improves its durability.

- Q: How does tinplate packaging handle exposure to different chemicals?

- Tinplate packaging is known for its excellent resistance to various chemicals, making it a reliable choice for storing and transporting a wide range of products. It can handle exposure to different chemicals without significant degradation or contamination.

Send your message to us

MR Tinplate JIS G3303 For Industrial Usage

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords