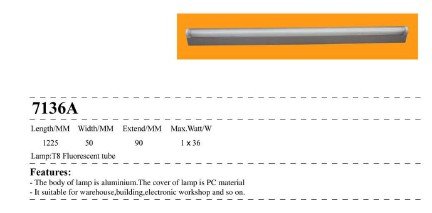

IP65 Waterproof Fluorescent Lamp Fittings

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 Pieces pc

- Supply Capability:

- 500 Pieces per Quarter pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Detailed Product Description

ip65 waterproof fluorescent lamp fittings

1.IP 65 for fluorescent lamp

2.Aluminium Alloy material

3.CE

- Q: Which kind of slideway is good for engraving machine?

- Look at the location of the engraving machine you need, speed or accuracy, now for engraving machine, only two choose one.

- Q: What hydraulic oil is used in the NC machining center guide?

- With professional rail oil, some sell hydraulic oil without hydraulic oil, which is used by hydraulic station.

- Q: What are the advantages of the silver rail?

- We use the Taiwan staf, which used silver and Abba before, and the quality is similar to that of ABBA

- Q: How to determine the mounting position of the guide bracket?

- 1, in determining the position of the guide bracket at the same time, but also consider the rail connection plate (link plate) and rail bracket) 1 can collide. Staggered net distance is not less than 30mm. 2, longer than 4m (including 4m) car rails, each should have at least two rail brackets. 4m to 3m long car rail is not subject to this limit, but the guide rail spacing shall not be 2m. If the manufacturer's drawings are required, they shall be constructed according to their requirements. 3, if the drawings are not clearly defined, the lower level rail support is taken as the base point, and every 2000mm is a row of rail brackets. Elsewhere (in case of said plate) spacing can be properly enlarged, but should not be ten 2500mm. 4, there is no elevator rails, brackets, buried iron elevator shaft lining, according to the requirements of the drawing guide bracket spacing, size and installation of the rail support vertical song to determine the guide rail bracket in the wall of the location. 5, when the drawing does not specify the next row guide rail bracket and the top row of the rail bracket position should be determined according to the following provisions: the next row guide bracket is arranged at the position corresponding to the pit decoration above the ground 10001m. The smallest row of racks is installed below the roof of the hoistway, no more than 500 m M.

- Q: Sliding door sliding rail has several models?

- The sliding doors can be roughly divided into two directions: push and pull tracks, single direction and sliding doors. Of these three, folding the sliding door will save more space. If consumers choose to do the sliding door, the door height is best to choose at more than 207 centimeters, so that it will not appear the entire room is too depressing. The best sliding door track size is 80 centimeters by 200 centimeters or so, so that the height of the door is very stable, but also good-looking.Of course, there are a lot of large-sized apartment, if consumers want to do these very high sliding door track size, still need to pay attention to some, because the door is very high, plus often push and pull the door, the height is not stable, it will be more easy to cause the door off phenomenon. If some sliding doors do good, can let people from the visual look room became larger, such as sliding door in the kitchen with an open type, a partition processing, and make the whole space more. Therefore, consumers for sliding doors of the choice of material should pay attention to, and different materials of the sliding door effect is also different, but it is best not to choose all transparent glass, which is easy to produce light pollution.

- Q: First ask why the potential difference between the metal rod in the guide rail 0

- Because of the smooth metal rail, the MPN resistance is ignored.

- Q: What are the good brands in Germany of linear guide and screw?

- Upstairs is quite right. Imported brands are mainly Japanese and german.

- Q: What mechanical equipment will use linear guide rail, if I machine equipment, not a general industry, I hope you will give some answers

- Semi automatic cutting machine runway must be straightThere is also the gantry crane rails are straight latheOh, there are lifts for construction sites, and some guides

- Q: CNC machine tools of rail damping mean, how to understand it is friction?

- With a knife is fixed on the machine tool feed system of CNC turning machine to offset the reduced friction resistance and the friction of the poor, in order to improve the feed system of NC machine tools (improve the guideway and friction characteristics (

- Q: What is the working principle of the linear guide rail?

- The linear guide rail is composed of tracks and sliders, and the slider moves in a straight line on the track. The slider is made of steel, ball / roller and circulator.

We believe in the purchasing policy of "try our best to bring your cost down". If you plan to purchase goods to reduce your cost, please let us have a chance to quote at your needs. We are capable of providing you with a profitable proposal with assurance.Hope we can build long-term and good business relationship.

1. Manufacturer Overview

| Location | Zhejiang,China |

| Year Established | 2010 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | North America 9.41 South America 5.88% Eastern Europe 10.59% Southeast Asia 4.29% Africa 6.06% Oceania 5.88% Mid East 4.88% Eastern Asia 5.12% Western Europe 8.24% Central America 5.06% Northern Europe 12.94% Southern Europe 7.94% South Asia 10.18% Domestic Market 3.53% |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Sydney,Angeles,Singapore |

| Export Percentage | 61% - 70% |

| No.of Employees in Trade Department | Above 50 People |

| Language Spoken: | English, Chinese, Spanish, Russian |

| b) Factory Information | |

| Factory Size: | Below 1,000 square meters |

| No. of Production Lines | 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered |

| Product Price Range | High and/or Average |

Send your message to us

IP65 Waterproof Fluorescent Lamp Fittings

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 Pieces pc

- Supply Capability:

- 500 Pieces per Quarter pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords