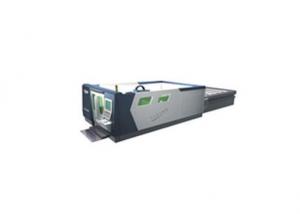

Laser CNC Cutting Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

Laser CNC Cutting Machine

CO2 laser tube

performance is stable

operation is easy

CE Proved

1.Applicable material of OL-1621:

Acryl,perspex, wood, rubber, leather,fabric, paper, cltoh, embroider and so on.

2.ptional Parts of JQ-1621:

USB port ( make the machine work without a computer)

Partial up-down worktable.

Parameter of OL-1621 Laser CNC Cutting Machine

Model |

QL--1621 |

Working area |

160cm*210cm / 63in*83in (L*W) |

Laser power |

130w/150w |

Laser type |

CO2 sealed laser tube,water-cooled |

Cutting speed |

0-50000mm/min (0-1968 inch/min) |

Laser Output |

1-100%software setting |

Resetting positioning accuracy |

≤±0.01mm |

Power supply |

220V/50HZ , 110V/60HZ |

Operating temperature |

0 - 45°C |

Operating humidity |

5 - 95% |

Min. shaping character |

English 1.0 x 1.0mm |

Graphic format supported |

BMP, PLT, DST, DXF, AI |

Software supported |

CorelDraw, PhotoShop, AutoCAD,TAJIMA |

Driving system |

3 phases stepper motor |

Equipment Dimension |

268cm*230cm*112cm

106in*91in*44in |

Packing Dimension |

278cm*240cm*130cm

109in*94in*51in |

Net Weight |

1200kg |

- Q: What is a "water gate" in an injection mold?

- The water pouring system, the gating system is divided into two kinds: the thimble, called pull needle (only one, the main channel, is the nozzle of the injection molding machine (Center), the other is the thimble thimble, up top material function)Hope to help you:)

- Q: Manually press the top into, if press do not put, will always top into the top retreat. Just push a little to let go, it will be back, but the computer also shows the top back, I think if the valve has a problem, or a problem with the oil cylinder, the problem, it will not have the computer display back ah, I just pressed into, will be automatically returnedExpert pointing ah!Trip switch type1 times the number of pins, semi-automatic, fully automatic, there will only be once, the election is repeatedly out, this common will not be wrongIf the trip switch off the top of the bad, it will not lock the mold, the top into the bad, it has been the top will not retreat, so few master assumptions are not established

- Contact with computer, program, you set a cycle, according to whether you how long he will run a cycle that is the top of the top back, general computer can choose to set it.

- Q: How about the height of the thimble? Why is it sometimes higher and smaller than the rear mold?How to design the thimble height?: the problem that a few days ago. I is often encountered in practice, hope master enlighten!:: y

- I heard a master say, once this problem is actually confused many people, especially in the thin wall injection molding, sometimes very annoying thimble printing. From material to consider:: y

- Q: How do you cure the thimble nail?

- Thimble nail is generally refers to nail point concave changeIf there is a punctate depression (such as a needle sized depression), it indicates a chronic lesion of an organ;If the concave point is larger, it is arranged like a grid, which indicates renal failure;

- Q: How should the rough edges appear in the injection molding process?

- If you have space, you can increase the top pinhole, re - cut with the thimble

- Q: How to push the plate and the thimble out of sync?

- That is the die (the 2 ejection structure), push the plate first, and then the thimble

- Q: What is wrong with the top of the lathe thimble?

- Is the tail seat biased?

- Q: When using dry high temperature resistant thimble lubricating oil, will the surface of injection products still have oil?

- It won't leave any oil. In fact, the thimble oil is mainly in the mold thimble, and can use the correct method to use ah.Contact the injection molded parts as little as possible.In this respect, we also provide solutions for different customers.

- Q: What is the difference between the needle and the thimble in the mold?

- Thimble, also known as push rod: a thimble, also known as two needlesThe ordinary thimble moves at the same time as the ejector plate, and the stroke is the same as the ejector plate.The movement of the two pin and the ejector plate is inconsistent and the stroke is different. Ordinary mould is used for the thimble, only in a few cases with grade two grade two thimble thimble, for example, the most common usage is to use ordinary thimble will be part of the product from the top die, and then use the product itself flexibility, level two thimble set no place to release.

- Q: Will the injection molding machine test die, thimble white what is going on, what should I do, ask for help?

- Top White is the general plastic injection molding products, injection molding, mold thimble pressure injury, pressure injury parts appear albino;Causes and elimination methods of defectsWhite hat, also called the top white. The reason for the appearance of "top white" is mainly due to the excessive force at the top of the white place. In the white part of the plastic parts, the chemical resistance and mechanical properties of them are greatly weakened. The detailed analysis is as follows. 1) injection moldIf the surface of the cavity is rough, the resistance of the mould will be increased and the top White will be reduced. Therefore, the surface roughness of the cavity should be reduced. If the top rod is at the weak part of the plastic parts, it will aggravate the phenomenon of top white. In this case, the ejection device should be placed at the wall thickness.If the mould is too small, the release resistance of the plastic parts will be increased, and the force of the plastic parts will be increased when the top is pushed out.In order to improve the strength of the top part, local strengthening can be done here, and the structure and wall thickness can be strengthened.If the contact surface between the rod and the plastic parts is too small, the local stress of the plastic parts is very large, so that it produces a top white. In this case, the sectional area of the end of the push rod should be appropriately increased.The plastic parts of cores, demoulding is difficult, is also prone to white hat, which will release the core and the plastic vacuum pieces, such as the core arranged in the valve to release the vacuum is a good method.

1. Manufacturer Overview

| Location | Shandong,China |

| Year Established | 2008 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | 11.11% North America 11.11% South America 11.11% Eastern Europe 11.11% Southeast Asia 11.11% Oceania 11.11% Mid East 11.11% Eastern Asia 11.11% Western Europe |

| Company Certifications | ISO 9001:2000;CE Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | QINGDAO,TIANJIN,SHANGHAI |

| Export Percentage | 71% - 80% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English, Chinese, Russian |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered |

| Product Price Range | Low and/or Average |

Send your message to us

Laser CNC Cutting Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords