Insulation Concrete Hollow Core Slab Forming Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Insulation Concrete Hollow Core Slab Forming Machine

1. Insulation Concrete Hollow Core Slab Forming Machine:

The machine uses hydraulic lifting system, easy to revolve. It can reduce labor intensity and improve production efficiency. Machine body adopts anti-rust technology. Key parts, like hopper are welded by stainless steel. Wearing parts like reamers, side form, vibration board, stock guide and other parts are all welded with alloy. Both sides of the wall panels can put reinforcement wires, diameter can reach 6mm. Work area is orbital or no orbital.

According to the specialty of the local materials, we provide matching method to insure customer produce standard panels (general materials: fly ash, slag, ceramsite, cinders, cinerite, pumice, vermiculite and so on). Reduce the overall cost of building, increase indoor usable space.

High production efficiency, annual output square meters above 150000m.

2. Main Features of Insulation Concrete Hollow Core Slab Forming Machine:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Simple structure, easy operate, less wear parts

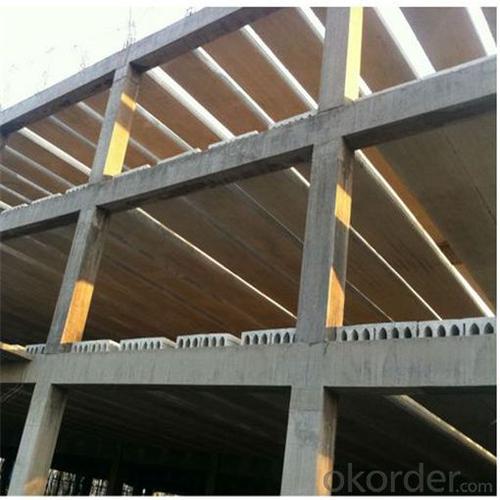

3. Insulation Concrete Hollow Core Slab Forming Machine Images:

4. Insulation Concrete Hollow Core Slab Forming Machine Specification:

Type | Aperture & diameter | Number and diameter of wires | Max span | Total power | Productivity (m/min) | Max. Load (KN/m2) | Overall dimension (mm) | Weight (kg) |

GLY180-1200 | 11/ peach | 12/9.5or12.7 | 9 | 18.5 | 1.1-1.3 | 16.16 | 2900X1500x1200 | 3300 |

GLY200-1200 | 8 /peach | 10/9.5or12.7 | 10 | 22 | 1.1-1.3 | 13.22 | 3700X1550X1550 | 5300 |

GLY250-1200 | 8/ peach | 10/12.7 | 12.6 | 33 | 1.1-1.3 | 11.1 | 3700X1550X1500 | 6200 |

GLY300-1200 | 6 /peach | 8/12.7 | 15 | 40 | 1.1-1.3 | 10.83 | 3700X1550X1500 | 6900 |

GLY380-1200 | 8 /rhomb | 8/12.7 | 18 | 39.2 | 0.8-1.0 | 12.27 | 4600X1850X1600 | 7500 |

Production Process

Rebar tensioning

Raw materials preparing

Molding

Our customers

5. Packing & Delivery

6. FAQ:

We have organized several common questions for our clients, may help you sincerely:

• What information we need to confirm with you before send a formal offer?

What kind of slab you want to make, wall panel, roof panel, lintel or something else?

Do you have exact slab size (slab thickness and width)? If not, please tell us the slab span, we will give you suggestion.

• What kind of machine do you have?

Our main products: large span GLY concrete hollow core slab machine, light - weight wall panel machine, lintel machine, column machine, hollow core slab cutting machine, concrete feeding dumper, high-strength steel wire tensioning machine, which amount to more than the types and more than four hundred standards. We can provide the whole plan and technology supporting for concrete precast component.

7. Our Service:

• We supply the technical supporting all the time.

• We supply one year warranty for whole machine.

• We supply low charge continue maintenance when warranty is expired.

• We supply free training to end-users

- Q: what are the auxiliary machinery found in ships?

- To be specific, auxiliary engines are the diesel or steam turbine engines that power the ships generators. Auxiliary machinery is any machinery eg pumps etc that are used to keep the main engine running and the ships domestic services operating. Other items required for cargo and non specific purposes such as lifts store cranes etc are classed as ancillary equipment. In addition to the above are the items required by class and other international regulations such as emergency systems,and systems required for safety.

- Q: How does operating machinery under water complicate mining procedures?

- Well it severely limits the type of power source you can use, corrosion of metal parts becomes a major factor, manipulation/positioning of machinery becomes extremely complicated, health and safety is even more of a problem, costs increase exponentially

- Q: Is there any common pattern between the two?While several ultra-Islamist countries have draconian laws to punish everyone who slanders god, CCP is known to punish everyone who slanders the Chinese Communist Party. CCP often resorts to informal detentions, punishments and disappearances which are completely outside the law, and so offer the government deniability and the victim no protection whatsoever.Do the Chinese people find any commonality between the Blasphemy Laws practiced in Islamist countries and the draconian policies of CCP?

- Have you also noticed that these religious fanatics use God to justify their actions rather than the laws that benefit the people? It is similar in that China uses the welfare of the state rather than a god to get to the same end, and that is domination of the masses.

- Q: what products does Zhengzhou Dayu machinery Co.,LD Produce?

- Hi okorder /

- Q: I am making a hypothetical business for school and have decided to create a business that makes whey protein powder from the whey left over from the making cheese. I have searched all over the net but I cant find any information on the machinery used in this process. Can anyone help

- nope

- Q: Looking at their lists of duties, it seems MR's are machinists, and MM's repair machines/pipes, etc.

- MR What they do The duties performed by MRs include: ? repairing and operating auxiliary machinery; ? calculating time and material needed for machine shop work and the repairing of auxiliary machinery; ? drawing sketches and preparing specifications for replacement parts; ? working from sketches and specifications to produce replacement parts; ? operating machine shop equipment, such as lathes, drill presses, shapers, bench grinders, milling machines, boring mills, power hacksaws and computer numerically controlled machinery; ? working with precision measuring instruments such as micrometers, depth gauges, verniers, calipers, gauge blocks, protractors and dial indicators; ? engraving metal and other materials; ? performing electroplating and flame spraying operations. --------------------------------------... MM What They Do The duties performed by MMs include: ? aligning piping systems for oil, water, air and steam, and controlling the operation of ship boilers and steam turbines used for ship propulsion and service systems; ? controlling operation of turbo generators used to produce electrical power; ? cleaning, adjusting, testing and performing other preventive maintenance on a ship's boilers, main engines, turbo generators and other auxiliary machinery including steering engines, elevators, winches, pumps and associated valves; ? operating and maintaining desalinization plants (distilling plants) to make fresh water from sea water; ? maintaining refrigeration plants, air conditioning systems and galley equipment; ? repairing or replacing valves, pumps, heat exchangers, compressors, steam turbines and hydraulic or pneumatic control devices; ? making entries in and analyzing machinery operating records and reports. --------------------------------------... You should be able to see the difference in primary duties.

- Q: I need to find artists or phootgraphers who used machines in their work, engines and steam engines.

- H. okorder /

- Q: What kind of material is used for processing shafts?

- Request the general words to choose 45 steel; require a lower case, cast iron on the line;

- Q: this is according to marx, i think its to do with how machinery changed society from primitive to industrial, im not sure tho, any help would be gratefully appreciatedthanks

- Machines okorder

- Q: Mechanical material forming cold forming and thermoforming What is the difference, the main processing of what materials

- Cold forming is not in the case of heating the material for punching, bending, stretching and other processing methods. Cold forming process cold forging, cold rolling, forging and so on. The main advantages of cold-formed steel structure: 1, compared with the thicker hot-rolled steel, cold-formed steel can be processed into smaller load and shorter span.

Send your message to us

Insulation Concrete Hollow Core Slab Forming Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords