Insulating Fire Brick GJM23 26 28 30 for Different Applications in Steel Industry

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 watt

- Supply Capability:

- 1000000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

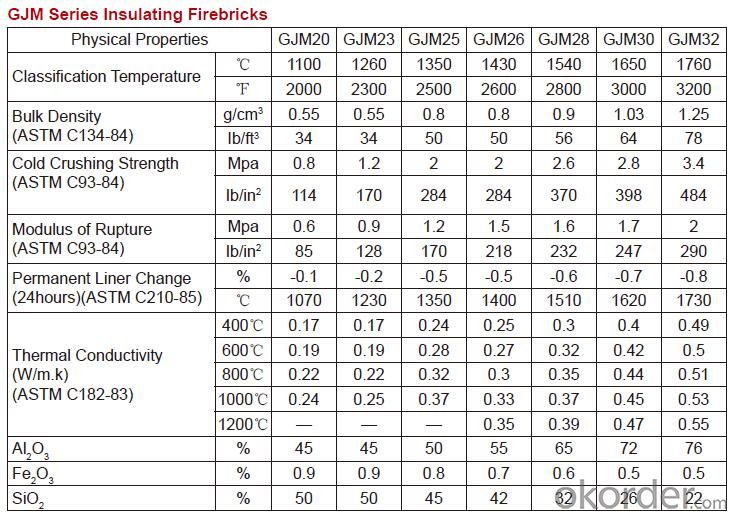

CMAX insulating firebricks are classified under temperature between 1100℃ to 1700℃, manufactured from high purity alumina clay.

Features

◆Light weight and low thermal conductivity

◆Low heat storage

◆Low iron and impurities

◆High thermal shock resistance

Application

CMAX insulating firebricks can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass.

Technical Data

This information, subject to change, is offered solely for your consideration. Users of our products should make their

own tests to determine the suitability of each product for their particular purposes.

Company Information

CNBM International Corp., established in 2004, is the business entity for international business and logistic of CNBM Group.

CNBM International is highly recognized by its business partners and clients all over the world and has established good business relationship with the customers in over 160 countries and regions all over the world.

Production Control

FAQ

Q:Are you a trading company or manufacturer?

A:CNBM is a large-scale central governmental industrial group with its own manufacturing sector, research and development sector, trading sector and logistics sector.

Q:I have some special requirement about specifications.

A:We have a well-rounded product range, which endows us with the capability of applying many special specifications. Please feel free to contact us with yours.

Q:Do you accept OEM service?

A:Yes, we do.

Q:What is your delivery time?

A:It depends on the size/complexity of your order and our own production schedule. Usually we provide a faster delivery than the industry's average.

Q:What is the payment term?

A:Our payment terms are negotiable.

Q:Can I have my own logo on the product?

A:Sure, we can apply your own logo on the products according to your drawings.

- Q: Can insulating fire bricks be used in high-temperature insulation panels?

- Yes, insulating fire bricks can be used in high-temperature insulation panels. Insulating fire bricks are designed to withstand and retain heat, making them an ideal choice for applications that require high-temperature insulation.

- Q: Do insulating fire bricks have a high insulating efficiency?

- Yes, insulating fire bricks have a high insulating efficiency. They are specially designed to minimize heat transfer and are effective in preventing heat loss or gain.

- Q: Can insulating fire bricks be used in pottery kilns?

- Yes, insulating fire bricks can be used in pottery kilns. They are commonly used as an additional layer of insulation to help retain heat and improve energy efficiency in kilns.

- Q: Are insulating fire bricks suitable for use in carbon black furnaces?

- Yes, insulating fire bricks are suitable for use in carbon black furnaces. Insulating fire bricks are made from refractory materials that have excellent insulation properties, which makes them ideal for high-temperature applications such as carbon black furnaces. Carbon black furnaces operate at extremely high temperatures, typically above 1,000 degrees Celsius, and the use of insulating fire bricks helps to reduce heat loss and improve energy efficiency. These bricks also have good thermal shock resistance, which is crucial for the cyclic heating and cooling that occurs in the furnace. Additionally, insulating fire bricks have low thermal conductivity, which helps to maintain a stable temperature inside the furnace and prevent excessive heat loss. Overall, insulating fire bricks are a reliable and effective choice for lining carbon black furnaces.

- Q: Are insulating fire bricks resistant to flame impingement?

- Yes, insulating fire bricks are resistant to flame impingement.

- Q: Do insulating fire bricks have a high heat storage capacity?

- Yes, insulating fire bricks have a high heat storage capacity. Insulating fire bricks are specifically designed to have low thermal conductivity, which means they are able to retain heat for longer periods of time. This makes them ideal for applications where heat storage is necessary, such as in furnaces, kilns, and other high-temperature environments. The high heat storage capacity of insulating fire bricks allows for efficient heat retention and distribution, ultimately improving energy efficiency and reducing heat loss.

- Q: Are insulating fire bricks resistant to warping?

- Yes, insulating fire bricks are generally resistant to warping. Insulating fire bricks are designed to withstand high temperatures and thermal shocks, which helps prevent warping. These bricks are made from lightweight materials such as clay, silica, and alumina, combined with additives to enhance their insulating properties. These additives also contribute to the brick's ability to resist warping. Additionally, insulating fire bricks undergo a specific manufacturing process that helps ensure dimensional stability and minimize the risk of warping. However, it's important to note that extreme and prolonged exposure to high temperatures can still cause some degree of warping, but compared to other types of bricks, insulating fire bricks offer a higher level of resistance.

- Q: Do insulating fire bricks have a low thermal conductivity?

- Yes, insulating fire bricks have a low thermal conductivity. These bricks are specifically designed to minimize heat transfer, making them an excellent choice for applications that require thermal insulation. Compared to regular fire bricks, insulating fire bricks have a lower density and higher porosity, which helps to reduce the flow of heat through conduction. This low thermal conductivity allows the bricks to act as effective barriers against heat transfer, keeping the surrounding areas cooler and increasing energy efficiency.

- Q: Can insulating fire bricks be used for insulation in autoclaves?

- Yes, insulating fire bricks can be used for insulation in autoclaves. Insulating fire bricks are designed to have low thermal conductivity, which means they can effectively retain heat and withstand high temperatures. Autoclaves require insulation to maintain a consistent temperature and pressure, and insulating fire bricks can provide excellent insulation properties in these demanding conditions. Additionally, their high strength and durability make them suitable for withstanding the intense heat and pressure cycles that occur in autoclaves. Overall, insulating fire bricks are a reliable and effective choice for insulating autoclaves.

- Q: Are insulating fire bricks suitable for high-temperature kilns?

- Yes, insulating fire bricks are suitable for high-temperature kilns. They are specifically designed to withstand extreme temperatures, making them an ideal choice for insulation in kilns. These bricks are made from lightweight refractory materials that have excellent thermal conductivity properties, allowing them to effectively retain heat and minimize heat loss. Additionally, insulating fire bricks have high resistance to thermal shock, ensuring their durability and longevity in high-temperature environments.

Send your message to us

Insulating Fire Brick GJM23 26 28 30 for Different Applications in Steel Industry

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 watt

- Supply Capability:

- 1000000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords