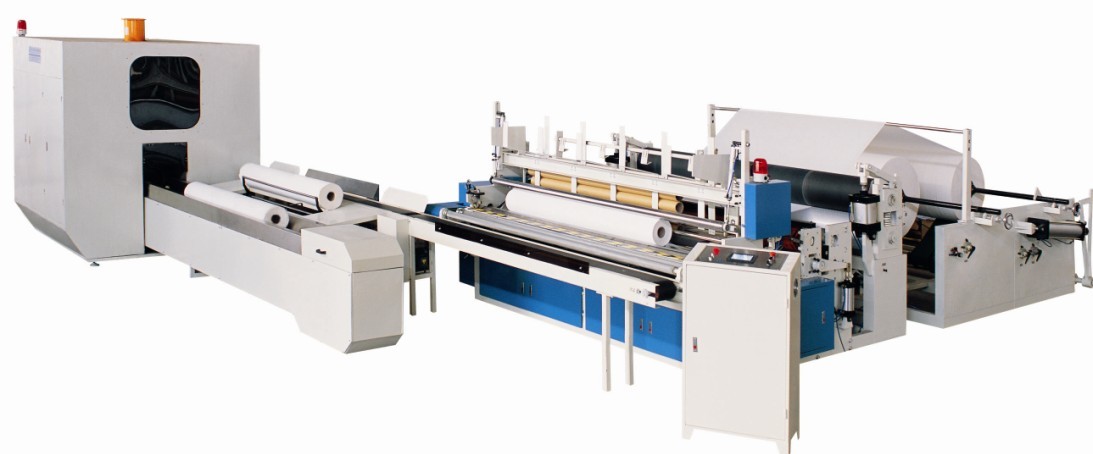

Industrial Roll Small Rolled Paper Production Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

DC-RSM-1092/3000II

Different from our previous machines and similar machines from other companies, our newly designed machines are innovative and improved with the below characteristics.

1. Toilet paper rewinding machine adopts full metal wallboard structure

2. Transmitted by timing belt

3. Speed increase by 20%-30% comparing with old frame type machine

4. Low working noise, durable transmission

5. Air pneumatic controlled perforating unit. Replace the old sawing blades with imported blades, which can wear well with long time. No need to adjust the blades within 1 year of usage. Delicate perforating lines and indicates superior grade quality.

6. High speed log saw machine with nice-designed grinding structure, full improve the sharpening effect. Metal wallboard structure, with improved clamp tool structure. Convenience at changing of clamps of different specifications.

7. High cost performance, obvious advantages among similar products.

Machine Model | 1575 | 2800 |

Width (mm) | 1800 | 2800 |

Finished Products Diameter | Φ 90~300mm (Tightness can be adjustable) | |

Finished Products Inner Diameter | 50 -76 mm | |

Jumbo roll diameter (mm) | Φ 1200MM | |

Jumbo Roll Inner Diameter | 3”,76.2 mm (other sizes can be ordered) | |

Perforation distance (mm) | 4 knife(blade),90~160mm;2 knife(blade),180~320mm | |

Production speed | 250 m/min | |

Parameter set | Man-machine Interface Operation System | |

Programmable controller | PLC program | |

Mechanical driving | Driven by stepless speed-regulator to guarantee the precise length of final products. | |

Jumbo roll stand | 2 plies | |

Air pneumatic system | 5 Pa (air-compressor), the minimum pressure 8kg/cm2 pa (customers should be prepared by themselves) | |

Power | 6.5-18KW (Frequency speed-regulate ) | |

Overall size | 7 X (2.8-3.8) X 1.8 M(L×W×H) | |

Embossment | ONE embossment | |

Embossment down roller | rubber roller | |

Perforation mode | Air pneumatic separating unit | |

DC-DH1575/3000II

High-speed Log Saw Machine

Rolled core length | Different in rolled core length, different in machine price. | |

Finished products diameter | sizes from 150-300mm can be ordered) | |

Horizontal cutting length | Changeable, Servo control, Tolerance ±1mm | |

Machine speed | 40-70 cuts/min, 1 rolls/cut | |

Operation speed | 60cuts/min, 1 rolls/cut | |

Function model | Spiral rotating the round blade & Continued Paper Roll Marching | |

Driving control | Servo motor driving | |

Knife grinding | Pneumatic grinding wheel, time can be controlled on panel | |

Round blade outer diameter | 1000mm | |

Clamping tool | Exchangeable (outer diameter of finished core can be designated.) | |

Finished products specification: | Rolled core outer diameter | 150mm-300mm |

Cutting length | 50mm-300mm | |

Left-over length | 25mm-50mm | |

Power | 15KW | |

Machine size | LXWXH (M) = 9 X 2.8 X 2.2M | |

Weight of equipment | 6.5T | |

Note: This production line is of high production efficiency. With the production speed of 250m/min, Machine Model 1575 can produce up to 4 tons of finished paper product in one working day (8 hours); while Machine Model 2800 can produce up to 6.5tons.

- Q: Where is secondhand corrugated paper packaging machinery available?

- Start a small yellow cardboard box factory, they have the best business, began the purchase of machinery, plant hire.In an unfamiliar field, we should listen to the opinions of experienced people.Carton is a supporting product of consumer products, so to speak, as long as people have consumption, enterprises and products, there will be no lack of product packaging.

- Q: What is the design basis of automated packaging?! Just for today!

- Increase productivity and reduce process costGerman packaging machinery, especially beverages, beer filling machinery and food packaging machinery, with high speed, complete sets, high degree of automation and good reliability and so on. Beverage filling speed up to 1200 bottles / D, when the cigarette packaging 12000 / min.. Increasing the speed of the machine is a complex problem. The faster the piece production cost is, the higher the use area of the workshop is. In addition, the speed of the motor is limited, so do not think how fast, how fast. In general, the speed increase by 15%, 20%, will lead to a series of complex problems. In addition to increasing the speed, the productivity can be solved from other channels:1. continuous or long work. Packaging machinery works a batch type and continuous type, design, design should strive for continuous work, also can improve the productivity; one device may also have multiple production lines, the production of the same product or several different products, but must improve the reliability.2. reduce scrap rate and provide fault analysis system. The loss of waste to production is enormous, not only product loss, but also material loss. So try to force to reduce the rejection rate; packaging machinery sale should also provide maintenance services for the fault analysis system, the modal analysis is carried out to find fault, or through the Inter network for remote diagnosis, the maximum to meet customer needs. In the future, the packaging machinery will be further intelligent, that is, the equipment itself to find fault, to solve their own failure, to reduce waste rate and failure rate, so that the normal productivity can be improved.

- Q: Bread packing machine Product features

- 4., high sensitivity photoelectric eye mark tracking, digital input seal cutting position, so that the seal cutting position more accurate.5. temperature independent PID control, better for all kinds of packaging materials.6. 、 positioning stop function, no sticking knife, no waste of coating.7. drive system is simple, more reliable work, more convenient maintenance.8. all control is realized by software, which is convenient for function adjustment and technical upgrading, and never falls behind.

- Q: What machine does the packing carton machine have?

- Since its establishment, the company has continued to provide specialized packaging equipment and transportation equipment for domestic first-class enterprises, as well as perfect solutions for automated transportation systems.

- Q: Food packaging process is not standardized, there is no responsibility?! For example, after the production of candy, because there is no corresponding packaging equipment, the need for artificial packaging

- Yes, automatic packing machine. I'm an employee of the automatic packaging machinery company.

- Q: What is the working principle of the pillow packing machine?

- Some packaging machinery manufacturers, many varieties of products, in the purchase of packaging machines, I hope a device can pack all their own varieties

- Q: What are the structures of the packaging machinery?

- Is a company engaged in outsourcing clients, packaging, processing, packaging equipment, leasing, services, sales in one of the specialized companiesSales of second-hand packing equipment according to the customer's product features and requirements. Reduce customer purchasing costsAccording to the customer's product characteristics and requirements. Select the best packaging equipment for customers, reduce customer purchasing costsPackaging equipment spare parts sales and maintenance services

- Q: What does the mechanical equipment include?

- Track roller type rail flat car track car battery car nailThese are, want to know more, you can go to the network building equipment to see there

- Q: Food, equipment, tools, containers, packaging materials, etc. shall comply with food safety standards or requirements

- 5009.101 determination of antimony in polyester resins and their moulding products for food containers and packaging materialsGB 13113 hygienic standard for polyethylene terephthalate moulding articles for food containers and packaging materials

- Q: Three dimensional packaging machine, transparent film packaging machine, transparent film three-dimensional packaging machine industry standards

- This standard specifies the terms and definitions, models, types and basic parameters, technical requirements, test methods, inspection rules and signs, packaging, transportation and storage requirements of the three-dimensional packaging machine for transparent film.

Send your message to us

Industrial Roll Small Rolled Paper Production Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords