Industrial Beer Brewing Equipment for Sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Processing: Fermenting Equipment, cutting-rolling-welding-polishing-assembling-testing-warehousing

Condition: New

Place of Origin: Zhejiang, China (Mainland)

Brand Name: KUNBO

Model Number: fermentation tank, KB-005

Processing Types: Alcohol

Certification: B&V; CE

Warranty: one year

After-sales Service Provided: Engineers available to service machinery overseas

Image:

Packaging & Delivery

| Packaging Details: | export standard package |

|---|---|

| Delivery Detail: | 25 - 45 days after deposit received |

Specifications

1. interior: mirror polished, exterior: semi-luster for main body

2. material: SUS304 or 316L

3. top dish head, conical bottom

| Industrial beer brewing equipment | |

| Company introducation | We Kuangbo is a production enterprise of pharmaceutical, dairy, food and beer-making equipment, alongside biological engineering, chemical containers, and bespoke products. Our products are widely used in beer production, pharmaceuticals, beverage industries, biotechnology and other fields. |

| Usage | it is used for beer fermentation |

| Material | 1.SUS304, 316L |

| 2.jacket: dimple jacket | |

| 3.insulation layer: PU | |

| 4.as to the thickness, we can make it according to your requirement. | |

| Configuration | safty valve, CIP spraying ball and pipe at the side of the tank, outlet with valve and racking arm as your requirement, temperature gauge and sample valve |

| Our advantage | 1.we can supply various kinds of volume, minimum 50L, maximun 10,000L and even larger. |

| 2.PU insulation is adopted, jacket will be dimple jacket | |

| 3.interior surface is 3Afinish and exterior is 2B finish | |

| 4.we also can equip you with a cooling system as your requirement. | |

| 5.competitive price and also higher quality tank. | |

| Minimum order | one unit |

| Payment term | T/T or L/C |

| Package | export standard package |

| Market | at home and abroad |

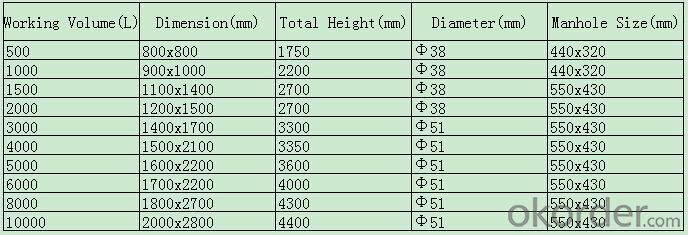

Technical Data:

- Q: One of my radiators was cold on top and warm on bottom, So I decided to bleed the radiator. Air was releasing and when water started to flow, I turned the valve the wrong way. About 1/2 gal of water bled from the radiator.

- i take it that you are speaking of a steam radiator, and boiler. the water in radiator is condensation of steam allowed to cool down inside radiator, if too much water collects it prevents normal flow of steam (heat) and you have no heat transfer (NO HEAT), do not adjust boiler pressure, adjustments are to be done only by qualified persons, a wrong setting can be very dangerous. however you can drain water from radiator as needed. open valve slowly allow to drain until you get steam, then close drain valve BE CAREFULL, STEAM WILL BURN YOU.

- Q: During the winter months when we have our Combi boiler running both the hot water and central heating, we get a interruption in our electrics. We've only seen it effect the TV and radio, however if we run the hot water tap for around 15-seconds the interruption goes away. When it interrupts the TV the channels freeze as though the reception is bad, this affects watching channels on Virgin, Sky and normal TV aerial. When heating is not on and the boiler is only used for hot water, there is no problem.We are going mad over this, please can someone help?

- Suppressors can be fitted to boilers to prevent radio interference when they switch on and off. These usually consist of an encapsulated series connected resistor and capacitor. These will perform their function if connected across the gas valve.

- Q: My Well Maclain Boiler takes a very long time to turn on and only stay on for 2 minutes. It does not respond to bridged thermostat wires. This boiler has a new gas valve with a pilot lite that is always on. What should I do?

- some day people will realize that boilers are a pain in the A### and get a furnace

- Q: give little explanation

- I am surprised by this question as actually iron has, and is, used in boiler manufacture. You have not said of what kind of boilers you are thinking. In general, iron has been replaced by steel as steel is both stronger and cheaper, and can be welded which makes the manufacturing process cheaper too. Cast iron is also more brittle than steel.

- Q: can i use spray paint near my gas boiler if i turn it off first?

- DO NOT USE ANY THING NEAR YOUR GAS BOILER THAT HAS ANY KIND OF FUMES. My husband was inflating a wheelbarrow tire in the basement, and was close to our gas furnace, which has a pilot light. The furnace was not running, but when the fumes from the can of tire inflator reached the pilot light, it ignited and he was encircled in flames for a second till the fumes were burned off. Luckily, he was not burned, but the wheelbarrow tire continued to burn and he had to carry it outside while it was burning. If you use a can of spray paint and that happens it may explode in your hand, or you could be burned by the fumes igniting like what happened to my husband. Another thing that could happen is a build up of fumes if the boiler is in an enclosed area and that could ignite and cause an explosion. (Sorry for the capital letters, but I wanted you to notice what I said). (Please be careful, fumes are very dangerous).

- Q: What is the difference between the row of the boiler and the hydrophobic body of the body, and what are the other

- Soda and steam, resulting in discharge (for) steam with water, reducing the quality of gas supply, and steam with water will also make the steam in the pipeline during the transport of condensate precipitation, the road to the pipeline water impact accident;

- Q: I have an old 100 Gallon boiler that heats my house. To say the least it is less than efficient and I am looking to save some money on gas this year. I have taken the insulation in my attic from a R almost nothing to an R39. I was wondering if it would be effective and safe to put 2 (because it is so large) water heater blankets around it. Although I do appreciate opinions I would like to hear from some pros who have an experienced answer.

- If the heater is designed for a blanket it may help a tiny bit on your bill to wrap it. You must examine the heater and make the decision if it is safe to do so. With the age and design of the boiler the insulation may be a waste of time though. On these old systems it may be a case of complete replacement to get any significant savings in the end.

- Q: We are thinking of getting a new boiler fitted and was just wondering how much other people paid basically so I dont get ripped off.Am having a quote tomorrow We will need everything replacing i think.

- fifteen hundred to two thousand dolars this was a few years back prices might of gone up since then.but i am sure not that much waite for your quote.good luck.

- Q: In the boiler, how to understand the "atmospheric pressure" and "pressure" these two concepts?

- Pressure hot water boiler can supply both low temperature water, but also supply high temperature hot water.

- Q: I'm wanting to buy or build a electric/wood fired water boiler to put in my in-floor heating system-any ideas?

- I okorder /

Send your message to us

Industrial Beer Brewing Equipment for Sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches