HZN40 Mobile Concrete Batching Plant

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

HZN/S Series Mobile Concrete Batching Plants are the result of advanced technology and engineering skills. They are new generation Batching Plants, the fruits of extensive R&D work, experience and accurate production facilities. This key concrete equipment is commonly used in large and medium-sized construction projects that need frequent site relocations, such as hydropower stations, roads, ports and so forth.

HZN/S Series Mobile Concrete Batching Plants can go thousands of kilometres on its own axle with a single towing vehicle for instance a trailer. Comparing other concrete batching plants, its advantages include:

☆ Compact design

☆ Easy installation and start-up

☆ Less foundation costs

☆ Fully automatic robust control system

☆ Reliable units (Siemens, WAM,Telemecanique, Beckhoff, Jotun, Pirelli etc.)

☆ Technologic and high quality production

PRODUCT DETAILS

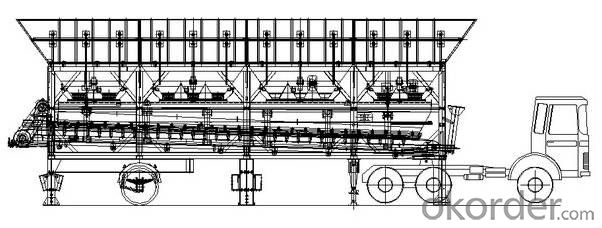

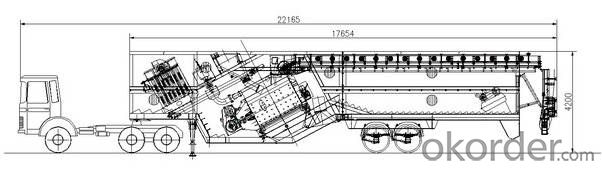

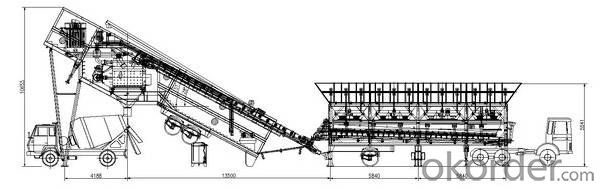

1. The aggregate weighing and conveying system, water supplying and additive agent supplying systems, weighing systems, mixing system, electrical control system and pneumatic system are fitted in one trailer.

2. Adopting module structure, designed as per the loading of standard container. All modules are in one trailing unit, it is easy for installation and disassembly and convenient for relocation.

3. Twin-shaft mixing host gives good product quality and high production efficiency. Perfect mixing can be done within ideal time period for dry-hard, half-dry-hard, plastic concrete and other types of concrete.

With discharge height at 3.8 m, it can work with any truck mixers.

4. It can store two or four types of aggregates at the same time and also with two cement silos and their respective screw conveyors;

5. All weight elements and control elements of weight system are from international well-known brands, controlled by computer, guaranteeing completely reliable and accurate weighing in rough conditions.

6. Platform or ladders equipped to each part needing maintenance and repairing. Good for maintenance.

7. The whole systemic computerized with dynamic panel display, to show clearly of the status of each component. Visualized monitor interface provides clear and real-time conditions of the site work. The plant operation data can be saved and printed out.

8. Electrical control system from international famous brands functions stably and powerfully. Automatic detection of abnormal working condition makes it easy for maintenance and trouble shooting.

9. It can be operated automatically or manually, and it is easy to switch between different operation modes.

SPECIFICATIONS

Model | HZN40 | |

Output (m3/h) | 40 | |

Mixer | Model | JN750 |

Mixing Power (kW) | 30 | |

Discharging Volume (m3)) | 0.75 | |

Aggregate Size (Gravel/Pebble) (mm) | ≤60/80 | |

Aggregate Dosing Tank Capacity (m3) | 4 | |

Hoisting Motor Power (kW) | 7.5 | |

Weighing Range and Accuracy | Aggregate (Kg) | 1500±2% |

Cement (Kg) | 400±1% | |

Fly Ash (Kg) | --- | |

Water (Kg) | Measured By Flow Meter | |

Admixture (Kg) | 20±1% | |

Discharge Height (m) | 3.8 | |

- Q: What raw materials and equipment do you need for your own admixture?

- Admixtures seem simple, but they are actually a practical science. You want to get the ideal admixtures from the books or the web, "that's quite", and you're in the concrete mixing station. The concrete cost control of the mixing station is relatively strict, and the performance of the admixture is different

- Q: What type of concrete mixer is needed for each hour of concrete 90 cubic meters?

- Many manufacturers will say that the HZS90 station is the one that makes 90 square concrete. In fact, the HZS90 station is supposed to produce 90 square concrete when it is in theory, and it is actually not up to 75 square

- Q: What are the supporting facilities for the concrete mixing stations?

- Concrete mixing equipment, concrete transport equipment, laboratory equipment, forklift, overpound equipment, ground pump, car pump etc.

- Q: How much water does a concrete mixer use every day?

- It is also a waste of water to flush the transports. Suppose you flush a vehicle with 1-2t water, rinse it 2-3 times a day, and use 20 cars a day for a medium size of a blender, 40 to 120 t a day. From this perspective, the reuse of washing water is very conducive to environmental protection and water conservation. The rational recycling of water in the mixing stations is also gradually being promoted. Our new hydraulic patent product concrete wastewater and sewage circulation recycling used by many domestic manufacturers, most of new mixing plant began to use the recycling equipment. The wastewater recovery system has made some efforts for the environmental cause of China.

- Q: Classification of concrete mixing stations

- Commercial concrete mixing station: single/double HZS90 concrete mixing station, single/double hzss120 concrete mixing station, single/double hzss240 concrete mixing station, single/double hzss240 concrete mixing station. Engineering concrete mixing station: HZS75 concrete mixing station, HZS60 concrete mixing station, HZS50 concrete mixing station, HZS35 concrete mixing station, HZS25 concrete mixing station. Mobile concrete mixer station

- Q: What are the facilities of the concrete mixing station

- It can be divided into five large parts of the mixing host, material weighing system, material conveying system, material storage system and control system

- Q: The average commodity concrete is mixed with a day to use how much fly ash

- That depends on the amount of concrete and the ratio, there is no absolute value. In concrete, the amount of cement is very large, and the price of cement per kilogram of cement is more expensive than the price of ash, gravel, sand and water. On the premise of guarantee the quality of concrete, concrete mixing station of utmost reduce the dosage of cement is to reduce unit cost of concrete price, search is one of the important measures to prevent concrete cracking.

- Q: What is the difference between a concrete mixer and a concrete mixer

- The simple point is: the bones of the mixing tower are on top, and the bone is measured directly into the blender. The bone material of the stirring station is below, and the bone material is measured and then transported into the blender after the slanting belt. In a popular way, it is called the building, which is called the second ascent. Higher initial investment mixing floor production line 400000 station, because of mixing building bin above, therefore the steel structure will be bigger, inclined belt will be relatively longer. But in productivity, the churn is about 20 per cent more productive. In the operation, the energy consumption and the failure rate will increase due to the frequent start of the inclined belt of the mixing station, while the mixing building will be relatively low. Of course, in appearance, the mixing building is a bit more imposing than a mixer-stand, which can sometimes have an unexpected effect on the business. In addition, there are some technology mixing buildings that can be used, and the mixing stations can't be used, because the equipment is different. It's worth noting that the difference between the initial and the mixing stations is not absolute.

- Q: Which staff does the concrete mixing station need?

- Mainly depends on how much station, whether can fully staffed, mainly included: general manager, deputy general manager, technology, webmaster, laboratory (deputy) director of the general, the production manager, sales managers, salespeople, scheduling, lab team leader, the operator (inspection), quality inspection, proportioning design, the material inspector technicians, machine operators, resposible, site, monitor of overhaul, maintenance engineer, loadometer, finance, cashier, mixers, pump truck drivers, company drivers, forklift driver, the handyman, chef, etc.

- Q: What is the daily routine of the concrete mixing station?

- Concrete mixing station is made by mixing console, materials weighing system, material conveying system, material storage system, control system of five systems and other ancillary facilities of building materials manufacturing equipment, the main principle of work is with cement as cementing material, mixing materials such as sandstone, limestone, coal cinder stirring, finally made into concrete, as the wall materials into construction operation.

Send your message to us

HZN40 Mobile Concrete Batching Plant

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords