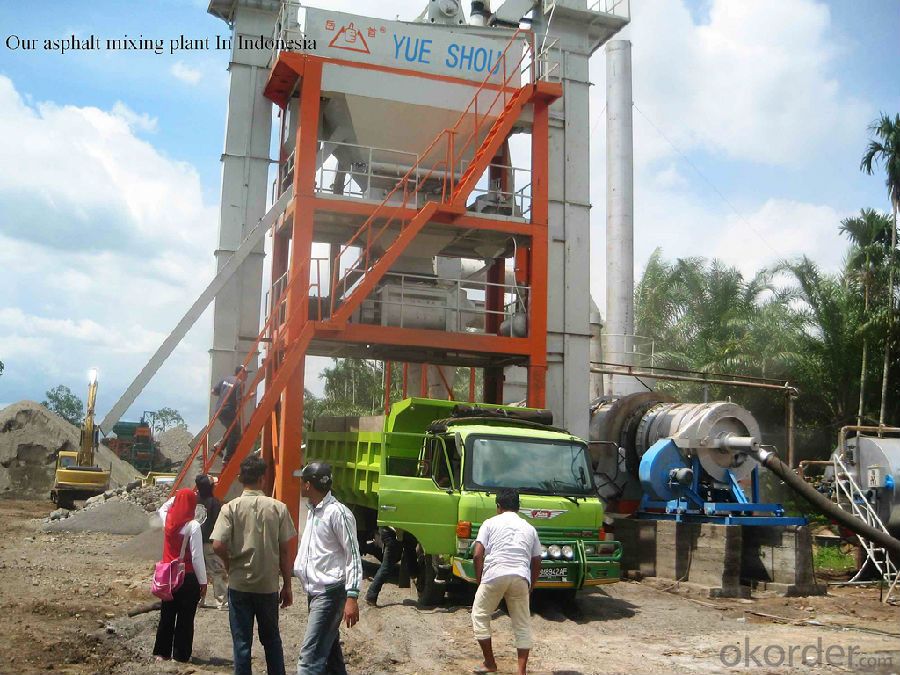

asphalt mixing plant LB800 capacity 64t/h,good reputation in russian,Top 10 in 2014,hot sale LB1500 in russian

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

LB800 Asphalt Mixing Plant with capacity 64t/h

Item | Description | Qty. (set) |

01 | Cold Aggregate Batching Machine and Feeders Group of four components, unit capacity of the aggregate hopper is 5M³ (full hopper), total capacity is 20M³; Adopts imported variable-frequency governor Continuous dosing belt & and driving reduction motor group, group of 4 units; The electric vibrato: 2 units | 1 |

02 | Feeding belt conveyor | 1 |

03 | The Drying Drum Ø1450×6300 MM, rotating speed: 11.3 RPM; Cylinder on frame, Rotation drive through electric motor and reduction box, The heat-preservation is 50mm rack wool and stainless steel | 1 |

04 | EBICO Gas burners Fuel :Natural gas | 1 |

05 | Cyclone dust collector |

|

06 | Bag dust collector |

|

07 | The hot aggregate elevator: capacity 80 T/H | 1 |

08 | The filler bin: 0.6 M³, the capacity of the filler elevator: 25T/H | 1 |

08 | The vibrating screen unit 4 grades, capacity 80T/H | 1 |

09 | The hot aggregate storage bin 4 numbers, the total volume is 10 M³, 4 units level indicator, temperature detector | 1 |

10 | The weighing devices The weighing unit for powder, aggregate and bitumen (each has one unit) | 1 |

11 | The mixing tower The main tower with supporting legs, repairing platform and guardrail | 1 |

12 | The mixer Capacity: 800 KG/batch, the motor power: 30KW | 1 |

13 | Vibration screen |

|

14 | Asphalt supply system and heating system 2 units 25 tons bitumen tank with hot oil heating system |

|

15 | Pneumatic control system | 1 |

16 | Electric control system |

|

17 | Control room |

|

18 | With 30ton bottom-set finished mixture storage tank | 1 |

- Q: What kind of sand do you need for a concrete plant? I don't know where to start!

- This is the premise of the 2.3-2.6 (which is better in this range) It can also be used by means of mechanism sand or mixed sand (coarse sand is used in a certain proportion), depending on the price of raw materials, to save the cost

- Q: What is the concrete of the mixing station?

- Concrete mixing stations are made of concrete, which is made of concrete for various construction sites, including commercial housing, concrete floor, industrial workshop and so on.

- Q: What are the supporting facilities for the concrete mixing stations?

- The facilities include concrete mixing equipment, concrete transportation equipment, experimental equipment, forklift truck, over-pound equipment, pump, and car pump etc. Concrete mixing station is mainly composed of mixing console, materials weighing system, material conveying system, material storage system and control system of large system and other ancillary facilities. Because building aggregate measurement compared with standing aggregate metering, reduced the four of the intermediate links, and the vertical blanking metering, saved measuring time, thus greatly improving the production efficiency, under the condition of the same model, mixing building production efficiency than mixing plant production efficiency by a third. Such as: HLS90 floor of production efficiency and production efficiency of HZS120 stand HLS120 floor of the production efficiency, production efficiency is equivalent to HZS180 stand HLS180 floor of the production efficiency is equivalent to the productivity of HZS240 station. Concrete mixers are a combination of concrete and concrete prefabrication. Because its mechanization, high degree of automation, productivity is high, and can guarantee the quality of concrete and cement, commonly used in concrete, long duration and site of quantities focus of large and medium-sized water conservancy, electric power, Bridges and other projects. Centralized with the development of municipal construction, stirring, provide commercial concrete mixing station has great advantages, and thus get rapid development, and to promote concrete pumping construction, the mixing, transportation, casting machinery joint operation to create the conditions.

- Q: What constitutes the js750 concrete mixing station

- The concrete mixing station consists of the mixing system, the aggregate supply system, the measuring system, the control system and the external supporting equipment. The main purpose of the mixing station is to mix concrete, also called concrete mixing station. HZS series products adopt international popular cement concrete mixing station quickly assembled module type structure, high-performance imported agitator, double machine double control way of computer control, prevent noise, prevent dust pollution, environmental design, is the new generation of cement concrete mixing equipment, applicable to urban commodity ready-mixed concrete, road and bridge, water conservancy, airports, ports and other large infrastructure construction project and concrete demand for large sites.

- Q: What does HZS mean in the HZS120 concrete mixing station

- HZ is the concrete mixing station. HZ is the concrete mixer. HZS is a concrete mixing station with a double sleeper shaft mixer

- Q: What chemical materials are used in the concrete mixing station?

- Do you mean admixtures? You want to make sure that you have a function, what purpose do you want to be able to make clear, usually with a buffer, a dilatant, and a densifier, and so on

- Q: The average commodity concrete is mixed with a day to use how much fly ash

- That depends on the amount of concrete and the ratio, there is no absolute value. In concrete, the amount of cement is very large, and the price of cement per kilogram of cement is more expensive than the price of ash, gravel, sand and water. On the premise of guarantee the quality of concrete, concrete mixing station of utmost reduce the dosage of cement is to reduce unit cost of concrete price, search is one of the important measures to prevent concrete cracking.

- Q: Which staff does the concrete mixing station need?

- Move the cement iron pipe, driver! technology, webmaster, laboratory (deputy) director of the general, production manager, sales managers, salespeople, scheduling, lab team leader, the operator (inspection), quality inspection, proportioning design, the material inspector technicians,

- Q: What is the daily routine of the concrete mixing station?

- Your question is fun, you ask is daily work refers to a person or the institution will have job or responsibility, and concrete mixing plant is short for a single search or mixing unit, I put the question to you "what's the concrete mixing station management personnel daily work including".

- Q: Does the concrete mixing station name have the name of the businessman concrete

- Yes, the general commodity concrete mixing station will write like this, the benefit of writing is simple and convenient, because the concrete three words are really too complicated! Zhengzhou zhengchen industrial production commodity concrete mixing station equipment.

Send your message to us

asphalt mixing plant LB800 capacity 64t/h,good reputation in russian,Top 10 in 2014,hot sale LB1500 in russian

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords