Hydroxypropyl Methy Cellulose HPMC ISO Factory Supply

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Building Construction Hydroxypropyl Methyl Cellulose (HPMC)

Brief introduction:

Hydroxypropyl Methyl Cellulose (HPMC) helps building materials apply more easily and perform better. They provide water retention and cohesiveness to mixtures. With special modification, it can be used to control thickening, water demand, workability, sag resistance, strength and other important properties of the final product.

It is widely used as thickener, adhesive, water preserving agent, film-foaming agent in building materials, industrial coatings, synthetic resin, ceramic industry, medicine, food, textile, agricultural, cosmetic and other industries.

Physical and chemical index:

Item | Specification |

CAS NO. | 9004-65-3 |

Appearance | white or light yellow powder |

Moisture Content | ≤5.0% |

PH | 4.0-8.0 |

Particle Size | min. 98% pass through 100 mesh |

Viscosity | 100cps-200000cps, 2% solution |

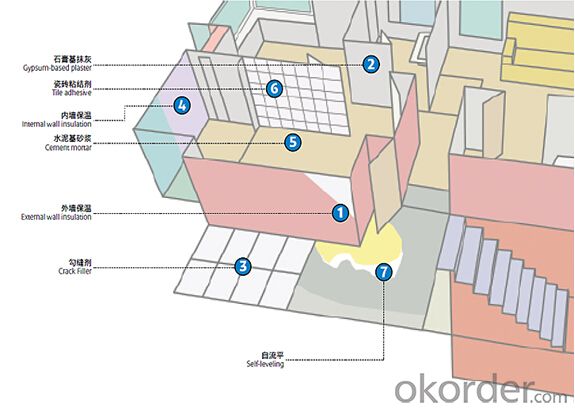

Application in Building:

External wall insulation system (EIFS)

>Bond strength: HPMC can provide the greatest degree of high adhesive bond strength of mortar.

>Performance: The mortar added HPMC has the right consistency, non-sagging. When using, the mortar is easy to work continuously, uninterrupted.

>Water retention: HPMC can wet the wall insulation easily, easy to paste, and also make other additional materials reach the best affects.

>Absorbent: HPMC can minimize the air-entraining volume, lower water absorption of mortar.

>Recommended brand: 75CMAX75000(S), 75CMAX100000(S), 75CMAX200000(S)

Interior and exterior wall interface agent

>Easy to mix, without of agglomeration: HPMC can significantly reduce the friction in the dry powder during the process of mixing with water, which makes it easy to mix and save the blending time.

>Water retention: HPMC can significantly reduce the moisture absorption by the wall. Good water retention can ensure the cement compound with a longer time, also can ensure that workers are able to carry out many times of scraping for the putty on the wall.

>Good working performance stability: even in high temperature environment, HPMC can still maintain good water retention. it is suitable for construction in the summer or hot areas.

>Increased water demand: HPMC can significantly improve the water demand of the putty materials. On the one hand, it improves the operational time after putty put on the wall, on the other hand, it can increase the coating are of the putty, which can make the formula more economical.

>Recommended brand: 75CMAX60000(S), 75CMAX75000(S)

Tile adhesive

>Water retention: HPMC can reduce the moisture absorbed by the substrate and the tile, retain the moisture in the adhesives as much as possible, making mortar still have adhesion after coating for a long time. Significantly extend open time and makes bigger coating area for the worker each time, and improve the efficiency.

>Improve bond strength, improve anti-slip performance: HPMC ensure non sagging of the tiles during working, especially for heavy tile, marble and other stone materials.

>Work performance: The lubricity of HPMC can increase the workability of the mortar significantly, which makes the mortar easy to coating and improve efficiency.

>Improve mortar wetting property: HPMC give mortar consistency, enhance the wetting ability of mortar and substrate, increase the binding strength of wet mortar, especially for the recipe with high water cement ration;

>Recommended brand: 75CMAX40000(S), 75CMAX75000(S), 75CMAX100000(S)

Crack Filler

>Workability: provide the right viscosity, plasticity, and easy to work;

>Water retention: can make the slurry fully hydrated, extending the working time and avoid cracking.

>Anti-hanging: HPMC can make a strong adhesion on the surface for the slurry and not sag;

>Recommended brand: 75CMAX40000(S), 75CMAX75000(S), 75CMAX100000(S)

Self-leveling mortar

>Prevent bleeding: HPMC can play a very good role to prevent the slurry sedimentation, bleeding.

>Maintain liquidity, and improve retention: low viscosity HPMC will not affect the slurry flow effect and easy to work. While possesses certain water retention, makes the good surface effect after self-levelling and avoid cracks.

>Recommended brand: 75CMAX400~600

Gypsum-based plaster

>Water retention: HPMC can retain moisture in the mortar, thus make gypsum completely solid. The higher the viscosity is, the stronger the water-retention capacity, vice versa..

>Sag resistance: allow the worker make the thick coating without causing ripple building.

>Mortar yield: For fixed weight of dry mortar, the exist of HPMC can provide more wet mortar.

>Recommended brand: 75CMAX75000(S), 75CMAX100000(S)

FAQ

Q1.Could we have the sample to test the quality?

Kindly send us your address, we are honored to offer you samples.

Q2. How does your company do regarding quality control?

CNBM a Chinese state-owned enterprise ranked 270th among the global fortune 500 in 2015,

have accreditation in line with standard:ISO 9001:2000,SGS,CIQ certificate.

Q3:What's your Delivery Time?

In generally, the delivery time is 25 days-30 days.We will make the delivery as soon as possible with the guaranted quality.

Q4:What is the convenient way to pay?

L/C , T/T ,Paypal, Western Union and Escrow are accepted,and if you have a better idea , please feel free to share with us .

Q5:Which mode of transport would be better?

In general,we advice to make delivery by sea which is cheap and safe.Also we respect your views of other transportation as well.

- Q: Chemistry is often said that the catalyst can change the material reaction rate, rate and speed What is the difference

- Rate refers to: the amount of time in the unit reaction, and speed, and the speed simply refers to the speed

- Q: why is palladium/platinum a good catalyst?

- Platinum As Catalyst

- Q: How are a catalyst and an intermediate similar? How are they different?

- A catalyst speeds up the rate of a reaction by lowering the activation energy barrier which is, presumably, the energy required to achieve the reaction intermediate. Catalysts are also not consumed in the reaction, they are regenerated towards the end. A reaction intermediate is a configuration that a molecule takes prior to achieving it's lowest energy form which would signify the end of the reaction. Intermediate usually are hard to isolate because of the incentive to go to the most stable configuration. How are they different? A catalyst is not a part of the reaction product and it doesn't get consumed. An intermediate in a reaction is transformed into the product. How are they similar? Well, catalysts drive the reaction and make it easier for the reaction for follow through. Since intermediates are high energy and thermodynamics tells us that low energy is favorable, the incentive for a high energy intermediate to drive down to it's stable for can also drive a reaction. I hope that helps. I hope it makes sense.

- Q: I was hoping to buy a land rover lr4 or lr2, but with the lr4 having gas mileage in the mid teens, i wanted to know if there is a way to improve it. I dont drive on the highway too much. I'd like to know if there is anything else to improve mileage too. I drive a lot of people around for functions, family, and others and I looked at other suvs but those two looked the best.

- Fuel catalyst is another name for fuel additive, the companies that make these additives make all kinds of claims how it increases power and reduces emiissions.. blah blah blah. Fuel catalyst is nothing more then a octane booster (gas engines) or cetane booster (diesel engines), it like all the other bogus products are worthless, octane booster will only show an improvement in performance IF the octane level in your current fuel supply is too low, higher octane fuel burns slower then lower octane fuel, that's how it quenches pinging and preignition both of which are caused by incorrect engine design and/or settings. Always use the lowest octane fuel that the engine will tolerate, if you have to pull advance out of the total timing then it needs more octane to run full timing and make max power, the only thing you can do to improve the quality of fuel in your tank is add a stabililizing additive such as (Stabil), it treats the fuel and prevents it from going stale or turning to varnish, it's especially useful when the vehicle is parked for long periods with fuel in the tank and carburetor, normally after a month or two of being parked the fuel in the carb turns to varnish and clogs the jets, with Stabil the fuel doesn't change composition.

- Q: Can manganese dioxide be used as a catalyst for various chemical reactions?

- Catalyst in the reaction process involved in the reaction, after the completion of the reaction was reduced to the original ingredients.For example: heating decomposition of potassium permanganate when added potassium permanganate potassium potassium permanganate decomposition process, the potassium permanganate is involved in the reaction, The specific way is not clear.Finally, the occurrence of potassium permanganate before and after the reaction of the catalyst changes in morphology, particles into powder, powder particles and so on.

- Q: Why extract the genome, the digestion is always not cut

- The enzyme, like the general catalyst, only catalyzes the thermodynamics of the permissible chemical reaction, shortening the time to reach the chemical equilibrium without changing the equilibrium point. The enzyme as a catalyst has no qualitative and quantitative changes before and after the chemical reaction. The mechanism of action of enzymes and general catalysts is to reduce the activation energy of the reaction.

- Q: In the chemical reaction will have to use the catalyst reaction, such as H2O2 === (MnO2) H2O + O2 ↑, then the catalyst in the end to participate in the reaction (that is, the catalyst itself is the reactant) If so, why are some of these substances in the reaction (these substances refer to the catalyst) in the reaction after the quality and nature of the change does not change?

- In the chemical reaction can change the chemical reaction rate of other substances (both can also improve), and its own quality and chemical properties in the chemical reaction before and after the material did not change called catalyst (also known as catalyst)

- Q: Chemistry: Does the catalyst participate in the reaction?

- The catalyst does not participate in the reaction, except that the reaction rate is changed.

- Q: how do catalysts help in green chemistry?

- Catalysts reduce the energy barrier for reactions, meaning they require less energy to make the forward reaction go. This means less heat, light, or other energy sources are required to perform the same reaction without a catalyst. Also, by definition, a catalyst is not consumed in a reaction and can therefore be recycled many many times before replacement is necessary.

- Q: What are the characteristics of the catalyst in the catalytic reaction?

- The role of the catalyst in the chemical reaction is to change the rate of chemical reaction, and its own quality and chemical properties do not change.

Send your message to us

Hydroxypropyl Methy Cellulose HPMC ISO Factory Supply

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords