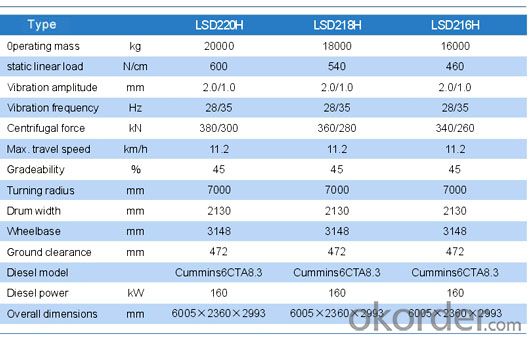

Hydraulic Single Drum Vibratory Road Rollers LSD220H

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 35 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hydraulic heavy duty vibratory rollers are suitable for compaction of non-cohesive materials such as gravel, crushed stone, sand-macadam mixture, sandy soil and rock filling etc. on base course, sub-base and embankment fill construction,which are ideal equipment for high-class highway, railway, airport, harbors, dams and large-scale industrial ground.

Cummins turbocharged diesel engine with rich power surplus in good performance above an elevation of 4000 meters.

Hydrostatic wheel & drum travel drive operated by a single lever at four range infinitely variable speeds, hydraulic pump and motors made from SAUER, REXROTH international advanced companies.

Adjustable frequency and amplitude vibration device with SAUER 90 series vibrating pump and motor.

REXROTH planet gear reducer integrated with wet multi-disc brake with oil-cutoff braking for reliable safety.

Unique streamline shape appearance with circle arc windscreen and curve engine hood for excellence sight.

Welcome you to visit our factory in China. Anything we can do, please feel free to let us know. We are sure your inquiries will get our prompt attention.

- Q: Roller vibration pump solenoid valve is new. Point road no problem. Sometimes there is no vibration. Sometimes not stop, you can always, flameout, restart no longer. Is it the pump problem? Under the guidance of an old master

- Upstairs said is extremely, check control circuit. I add the following points: 1: ask: do you say the solenoid valve for the new? Why is it new? What was the trouble before?. 2: asked: "you say that the circuit is no problem, how to judge?" According to where? I put forward the inspection idea: first, judge the circuit problem: take the solenoid valve coil at both ends, turn on the power, open the Qiang Qiangzhen or weak earthquake. With a screwdriver into the coil inside the hole, if there is magnetic, that the line is through, the size of the shock, try. Instead, the coil is not called. There's something wrong with the line.

- Q: Is the steel roller roller a vibratory roller?

- There are many types of rollers, which are divided into diesel and gasoline hand vibration rollers according to the difference of hydraulic oil burning. The oil used in the maintenance parts is also different! You can Baidu Shandong Jin Yao under detailed instructions!

- Q: Where can I find someone who rents a roller? One hundredExcuse me, is there a master who rents road rollers here in Sichuan, Meishan? Or you know all you can rent a road roller. I am looking for a few roller rental information, are empty. Who can help me find a rent roller, really mad!! Thanks

- I know there is a road roller in Meishan, and he knows quite a lot of people who do road rollers, loaders and excavators.

- Q: What is the concept of the static line pressure of roller?

- I can give you a method for calculating the line pressure: the line pressure = the weight of the steel wheel, W (kg) divided by the width of the steel wheel, L (CM)What is line pressure?. This is where the pressure is concentrated in the narrow part of the contact surface. In fact, the state of the line.

- Q: What's the difference between the German BMW roller and the German BMW? Which is better? Thank you for your advice

- BMW is roller imported from the German company BMW; BMW case is the German BMW company in Shanghai China company, BMW roller assembly, in order to distinguish the two different names, the price is also different; BMW Dalian canal Yici engine, some structure also is domestic production; there are great differences between BMW and Germany the quality of! Currently the best brand roller is Sweden Dynapac produced Dynapac roller!

- Q: Vibratory roller pressure and steel roller compacted what is different

- You should make the cement stabilized layer of double steel wheel vibratory roller, you should first use vibratory roller vibration compaction, and then do not open vibration to smooth surface. Just do not open the vibration pressure several times, the static pressure only to surface dense, but the bottom is still more loose

- Q: What documents do I need to open the road roller?

- 1, roller operation certificate 2, yes, 3, own registration examination hundreds of pieces, into the training course, then forget it

- Q: Brief introduction of tyre roller

- A tire roller is a machine operated by a plurality of pneumatic tyres for the road. The roller of tyre roller adopts pneumatic tyres, usually 3~5 front wheels and 4~6 rear wheels. If the change of inflation pressure can change the ground pressure, the range of pressure regulation is 0.11 ~ 1.05 mpa.The tire roller adopts hydraulic, hydraulic or mechanical transmission system, single shaft or full axle drive, wide base tire, articulated frame structure, three point support. Compaction process has the role of rubbing, so that the compaction layer particles are not damaged and embedded, homogeneous and dense. Good maneuverability, fast speed (up to 25 km / h).

- Q: That will not corrode the pavement, such as diesel oil, salad oil as are oil corrosion, although not corrosion of asphalt, but the corrosion wheel is not good, who have the sticky proof measures better, thank you "Nd}S + E, bbs.3c3t SqS + H human Y ~ ~ V

- Tyre roller is not allowed in modified asphalt pavement!! If forced to use, the only way is that the rubber wheel is opened slowly, followed by three people holding a mop covered with diesel, while walking on the rubber wheel above, this is the only non stick method. But pavement damage is not recommended. The biggest drawback is that the modified asphalt mixture rolling temperature is more than 150, and the tires are also damaged. Therefore, the specification is not allowed. (tyres, tyres, nearly smooth, without lines)

- Q: Why does the roller shake from the building when it's past the building?

- Roller vibration force is generally around 30 tons, that is to say, with a hammer of about 8 tons on the ground, so the building will shake ah. Sometimes, when the roller does not vibrate, the building also shakes. That is because the ground is uneven and the steel wheel of the compactor impacts the rough ground.

Send your message to us

Hydraulic Single Drum Vibratory Road Rollers LSD220H

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 35 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords