Hydraulic Jacking Bridge

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Hydraulic Jacking Flat Bridge's

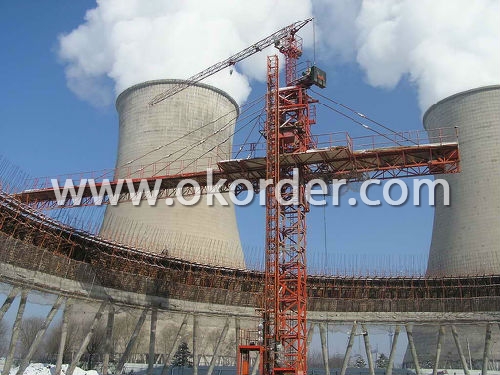

A new type of construction equipment which is used coordinated with multifunctional hoist in Cooling Tower's construction. It can be attached by hoist lifting, providing a platform for level transportation of the long reinforcing bars and concrete.

We have passed ISO9000 quality system authentication. We have powerful R&D centre and all of our products are equipped with advanced motor, safety device and steel material.

Features are follows:

The bridge body and the level bridge are well shaped structure with good rigiity and precise stress

The hydraulic jacking method ensures safety and convenience during the operation of the bridge

The operation scope can be adjested according to the constuction precedure of the building

At the top of the bridge there is a minor downward slew tower crane which is used for the lifting of steel bars and materials

To ensure the safety during the operation, it is installed with sensitive lifting,slewing,range -change,torque limting mechanisms and front-rear bridge torque alarms.

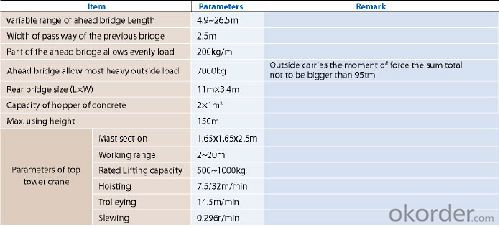

Specification

Range of ahead bridge Length (m) 4.9~26.5

Width of ahead bridge(m) 2.5

Evenly load of the ahead bridge (kg/m) 200

Max. load of the ahead bridge(kg) 7000

Rear bridge size(L×W) m 11×3.4

Capacity of concrete hopper (m3) 2×1

Max. height of bridge (m) 150

Working environment temperature 50℃

FAQ

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide &

protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity

is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

- Q: Is it possible to utilize a building hoist for lifting materials during demolition projects?

- <p>While a building hoist is typically designed for construction purposes to lift materials and personnel, it is not advisable to use it for demolition work. Demolition involves hazardous conditions with falling debris and unstable structures, which can compromise the safety and integrity of the hoist. Instead, specialized equipment like wrecking balls, hydraulic shears, and cranes are more suitable for demolition tasks. These are engineered to handle the heavy loads and unpredictable conditions associated with breaking down structures safely.</p>

- Q: This question asks for a comparison between manual and automatic lifting systems used in construction equipment, highlighting their distinct features and operational differences.

- <p>Manual lifting systems in construction equipment rely on human effort to lift and move materials. They are often less expensive, require less maintenance, and are suitable for lighter loads or smaller-scale projects. However, they are labor-intensive, can be slower, and pose higher risks of injury due to the physical demands. Automatic lifting systems, on the other hand, use mechanical or electronic means to lift and move materials. They are more efficient, can handle heavier loads, and reduce the risk of injury by minimizing manual handling. These systems are often more expensive and require regular maintenance but offer precision, speed, and ease of operation, making them ideal for large-scale construction projects.</p>

- Q: Is it possible to use a building hoist to lift multiple items simultaneously?

- <p>Yes, a building hoist can be used for lifting multiple objects at once, provided that the combined weight of the objects does not exceed the hoist's load capacity. It's important to ensure that the hoist is designed for such use and that safety precautions are strictly followed to prevent accidents. The objects should be secured properly to avoid any shifting during the lift, and the operation should be conducted by trained personnel to maintain safety standards.</p>

- Q: This question asks for the process of changing the height at which a building hoist operates.

- <p>Adjusting the height of a building hoist typically involves a few key steps. First, ensure the hoist is powered off and disconnected from any power source to ensure safety. Next, locate the hoist's height adjustment mechanism, which may be a set of bolts or a telescoping column. Loosen any locking nuts or bolts that secure the current height setting. Adjust the hoist to the desired height by raising or lowering the platform or mast. Once the desired height is reached, tighten the locking nuts or bolts to secure the hoist in place. It's crucial to check the manufacturer's guidelines for your specific hoist model, as the process may vary. Always follow safety protocols and consult with a professional if you're unsure about any steps.</p>

- Q: Is it possible for a single lifting device to simultaneously lift multiple objects with varying weights?

- <p>Yes, a single lifting device can be used to lift multiple objects at once with different weights, provided the total weight does not exceed the device's lifting capacity. The device must be designed to handle the combined weight and ensure even distribution of the load. Safety measures and proper securing of the objects are crucial to prevent accidents. It's important to follow the manufacturer's guidelines and never exceed the maximum load capacity to avoid damage or injury.</p>

- Q: How many floors are built to use the construction elevator? With six floors?

- The country stipulates above 7 floor to be installed elevator, of course 7 below can be installed not outfit, average 7 floor below is a ladder of ladder of ladder of ladder of ladder of ladder of ladder of ladder of ladder of stairs and so on

- Q: Elevator installation approach, need to give the total package (inspect) what data, come a master to answer the detail point

- Elevator random documents, material verification documents, product certificate.

- Q: Is it possible to use a lifting device to lift objects that are heavier than its specified maximum load?

- <p>No, a lifting device should never be used to lift objects that exceed its rated load capacity. Doing so can lead to catastrophic failure of the device, potentially causing serious injury or death. Always adhere to the manufacturer's specifications to ensure safety and prevent accidents. Overloading a lifting device can result in structural damage, compromised safety mechanisms, and increased risk of collapse or dropping the load. It is crucial to respect the load limits to maintain the integrity and reliability of the lifting equipment.</p>

- Q: Explain the distinctions between electric and electric-motorized building hoists.

- <p>Electric building hoists are powered by electricity and typically use a motor to lift and lower loads. They are designed for vertical transport of materials in construction settings. Electric-motorized hoists, on the other hand, are a specific type of electric hoist that emphasizes the use of an electric motor for operation. The primary difference lies in the level of automation and control. Electric-motorized hoists often have more advanced features like variable speed control and may be integrated into larger systems for automated material handling. Both are efficient, but electric-motorized hoists offer higher precision and control, making them suitable for more complex applications.</p>

- Q: The elevator is banned from using elevators for more than a class of high winds

- When the wind speed is more than 13 meters per second, the installation and disassembly is forbidden. When the wind speed exceeds 20m/s and the weather, such as hail, the elevator should not be used. This is the norm M/s is about 8, and 13m/s is about 6

1. Manufacturer Overview

| Location | JIANGSU,CHINA |

| Year Established | 1998 |

| Annual Output Value | Above US$10 Million |

| Main Markets | CHINA |

| Company Certifications | ISO 9001:2000; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 0.6 |

| No.of Employees in Trade Department | 300 People |

| Language Spoken: | English;Chinese; |

| b) Factory Information | |

| Factory Size: | Above25,000square meters |

| No. of Production Lines | Above 1 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Hydraulic Jacking Bridge

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords