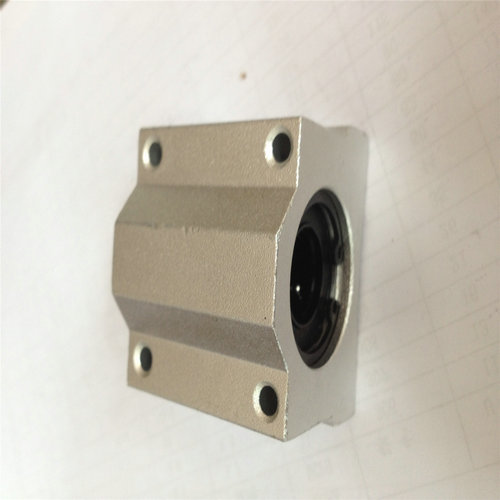

slide bearing absorber bushing plain bearing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

plain bearing, slide bearing, absorber bushing

1.Good load capacity and anti-wear.

2.Widely used in the Lead-free field.

Plain bearing, slide bearing, absorber bushing

We CHANGSHEG BEARING is a direct manufacturer specialized in producing bushings with more than 10 years . We believe that we can provide you the best products and services!

du bush, pump bush, shock absorber bushings

| Max.Load | Static | 250N/mm2 |

| Dynamic | 140N/mm2 | |

| Oscillating | 60N/mm2 | |

| PV limit | Dry | 3.6N/mm2.m/s |

| Oil | 50N/mm2.m/s | |

| Temp.limit | -195°C~+280°C | |

| Friction Coeff. | 0.03~0.20μ | |

| Speed limit | Dry | 2m/s |

| Oil | 5m/s | |

| Thermal conductivity | 2.41Kcal/M.br.c | |

| Coeff. Of linear expansion | 27×10-6per°C | |

- Q: Do you have a standard model?I design a rotating pan head, the motor is a cantilever state, the motor shaft is particularly easy to bend, want to add a sliding bearing on the shaft, but the sliding bearings know too little, help ah!

- See how large your specifications, linear sliding bearing IKO is better, there are standard products. You will see the thickness of the shaft, can contact our company 51105080-103, Shanghai sidaquan Bearing Co. Ltd.

- Q: What's the connection between the crankshaft and the sliding bearings?

- The crankshaft bearing is split sliding bearing is installed in the main bearing crankshaft, connecting rod and crankshaft support operation, is to open sliding bearing is mounted on the connecting rod hole and crankshaft crank shaft (connecting rod), the connecting rod is connected with a crankshaft.

- Q: What effect does the sliding bearing have on the top gap?

- There must be a gap between the clearances.The fit between the sliding bearing and the shaft is clearance fit. The top gap is normally pressed by lead. The top clearance is 1/1000 or 1/1000 of the axle neck, and five of the gap is 1/2 of the top clearance.

- Q: Sliding bearings relative clearance 0.001 what?

- Accuracy should be up to 0.001 of the standard

- Q: Brief introduction of oilless plain bearings

- he oil film also has a certain vibration absorption capacity.But the starting friction resistance is larger. The shaft supported by the bearing is called the shaft diameter, and the part corresponding to the shaft diameter is called the bush. In order to improve the friction properties of the bearing surface, the antifriction material layer, which is cast on its inner surface, is called the bearing lining.

- Q: What are the conditions for forming sliding bearings and dynamic oil film lubrication?

- Well sealed, oil pressure normal, extreme pressure of oil meets demand.

- Q: Bearing is the bearing?

- The sliding shaft and the shaft seat is not the same, not a class.

- Q: Establishment of oil film bearing capacity of dynamic sliding bearing and several conditions to ensure full liquid lubrication

- Establish three conditions: relative speed, reasonable wedge, adequate lubrication. This is a necessary condition.

- Q: What are the common sliding bearing bushing materials? What are the characteristics of each?

- 1) grey cast iron, which is used in low speed, light load and no impact load, and is commonly used in HT15-33 and HT20-40.2) copper base bearing alloy. Commonly used ZQSn10-1 bronze and ZQA19-4 bronze, suitable for medium speed, high turbidity and impact load conditions.

- Q: The difference between rolling bearings and plain bearings in ball mill

- But according to my personal inference, establishes first should be the production process - rotary grinding method, then in order to solve the problem of rotary bearing will lead to bearing hollow ball mill, but at the time of the machining level and the production process of hollow bearing cooling considerations, and ultimately selected the sliding bearing. This inference is based on technological transformation and upgrading as a clue. So it's for reference only. Secondly, compare the advantages and disadvantages of bearing and bearing the problem itself is wrong, bearing and bearing you concept is not clear, take the two kinds of commonly used ball mill bearing is divided into sliding bearing and rolling bearing, what you said is referred to as sliding bearing bush (or known).

Send your message to us

slide bearing absorber bushing plain bearing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords