Bearing Bearings 7017 Angular contact ball bearings 7017 Angular contact ball bearing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Sepcification:

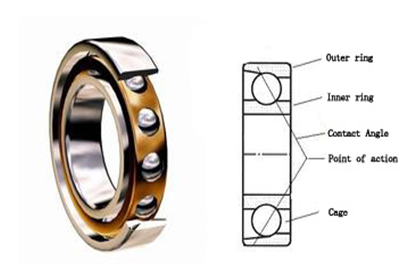

Angular contact ball bearings can bear radial load and axial load at the same time and also can bear pure axial load. Their ability of axial load is determined by contact angle and is increased with contact angle increasing; speed limit is higher; stiffness is big and can be pre-adjusted. They are applicable to high-speed and high-precision site.

Product application:

- spindle and other high speed precision mechanical spindle

- aircraft engine spindle

- high frequency motor

- printing machinery

- air compressor

- gas turbine

- jet engines

- turbines

-pump

| Design ations | Principal dimensions (mm) | 〆15º | 〆25º | ||||

| Limit speed | Limit speed | ||||||

| d | D | B | Basic load rating | Lubrication | Rated load | Lubrication | |

| Cr Cor | Grease Oil | Cr Cor | Grease Oil | ||||

| 70 Series single angular contact ball bearings | |||||||

| 7003 | 17 | 35 | 10 | 6.7 4.9 | 44000 66000 | 6.4 4.7 | 39000 59000 |

| 7004 | 20 | 42 | 12 | 9.6 6.3 | 37000 55000 | 9.2 6.0 | 33000 49000 |

| 7005 | 25 | 47 | 12 | 12.9 8.7 | 33000 49000 | 12.3 | 29000 44000 |

| 7006 | 30 | 55 | 13 | 15.7 11.6 | 27000 42000 | 14.9 10.9 | 23000 37000 |

| 7007 | 35 | 62 | 14 | 19.3 17.5 | 19000 33000 | 10.4 10.3 | 19000 33000 |

| 7008 | 40 | 68 | 15 | 19.9 19.1 | 18000 31000 | 18.9 18.2 | 16000 27000 |

| 7009 | 45 | 75 | 16 | 26.7 25.3 | 16000 27000 | 25.4 24.1 | 15000 25000 |

| 7010 | 50 | 80 | 16 | 27.6 27.5 | 15000 25000 | 26.2 26.2 | 14000 23000 |

| 7011 | 55 | 90 | 18 | 36.7 37.1 | 13000 21000 | 34.8 35.3 | 12000 19000 |

| 7012 | 60 | 95 | 18 | 37.8 | 13000 21000 | 35.8 38.0 | 11000 18000 |

| 7013 | 65 | 100 | 18 | 38.9 42.9 | 12000 19000 | 36.8 40.7 | 10000 17000 |

| 7014 | 70 | 110 | 20 | 49.9 55.5 | 11000 18000 | 47.2 52.7 | 9000 16000 |

| 7015 | 75 | 115 | 20 | 51.3 59.2 | 10000 17000 | 48.5 56.2 | 8500 15000 |

| 7016 | 80 | 125 | 22 | 61.6 70.4 | 9000 16000 | 58.3 66.9 | 8000 14000 |

| 7017 | 85 | 130 | 22 | 63.6 | 8500 15000 | 59.9 71.3 | 7500 13000 |

| 7018 | 90 | 140 | 24 | 66.9 | 8000 14000 | 63.2 79.7 | 7000 12000 |

| 7019 | 95 | 145 | 24 | 79.1 97.6 | 7500 13000 | 74.8 | 6500 11000 |

| 7020 | 100 | 150 | 24 | 81.2 103.3 | 7000 12000 | 76.7 | 6000 10000 |

| 7021 | 105 | 160 | 26 | 93.9 118.2 | 6500 11000 | 88.8 | 6000 10000 |

| 7022 | 110 | 170 | 28 | 110.4 139.8 | 6000 10000 | 104.4 132.8 | 5700 9000 |

| 7024 | 120 | 180 | 28 | 112.7 148.7 | 6000 10000 | 106.3 141.1 | 5700 9000 |

| 7026 | 130 | 200 | 33 | 144.8 190.8 | 5700 9000 | 136.8 181.0 | 5000 8000 |

| 7028 | 140 | 210 | 33 | 148.7 202.6 | 5000 8000 | 140.4 192.2 | 4600 7500 |

| 7030 | 150 | 225 | 35 | 168.4 232.5 | 4600 7500 | 159.1 220.6 | 4000 6500 |

| 7032 | 160 | 240 | 38 | 189.1 264.5 | 4000 6500 | 178.6 251.0 | 3800 6000 |

| 7034 | 170 | 260 | 42 | 205.6 299.3 | 3800 6000 | 194.2 284.0 | 3300 5300 |

| 7036 | 180 | 280 | 46 | 229.5 352.1 | 3500 5700 | 216.8 334.1 | 3000 5000 |

- Q: What is the selection principle of grease for plain bearings?

- 2. Selection of grease for sliding bearingsLoad 1-6.5MPa, shaft neck circumference speed below 1m/s, the maximum working temperature of 50-100 DEG C, the No. 2 lithium greaseLoad > 5MPa, journal circumferential speed 0.5m/s, maximum operating temperature 60 DEG C, roll No. 2 calender greaseThe load is less than 1MPa, the circumferential speed of the journal is below 1m/s, the maximum working temperature is 75 DEG C, and the No. 3 calcium base grease is usedLoad 1 - 6.5MPa, journal circumferential speed 0.5-5m/s, maximum operating temperature 55 DEG C, and use No. 2 calcium base greaseLoad > 6.5MPa, journal circumferential speed 0.5m/s below, maximum working temperature 75 DEG C, choose No. 3 calcium base greaseThe load is less than 6.5MPa, the shaft neck circumference speed 0.5-5m/s, maximum working temperature of 120 DEG C, the No. 2 lithium greaseLoad > 6.5MPa, journal circumferential speed 0.5m/s below, maximum working temperature 110 degrees, choose 2 calcium sodium base greaseCalcium base grease should be considered when the temperature is 75-120 degrees centigrade in humid environment;The working temperature should be below 75. The calcium base grease No. 3 should be considered. If not, the aluminum base grease can be used instead;The temperature at 110-120 DEG C, available barium grease or grease, lubrication, consistency to be smaller.

- Q: In what circumstances, lubricant viscosity should be smaller?

- It's not a temperature problem. You should use a little oilThe simplest way is to use the fire under the oil, if it will change the water, this kind of lubricating oil will not have no, you can use800 is usually OK

- Q: Which one is good for sliding bearings?

- Our company has perfect product research and development system, designed and developed a number of new products and patents.

- Q: How to change the sliding bearings of railway freight cars to rolling bearings?

- This is not very good, after all, the railway is demanding, and easily change, I am afraid can not meet the established requirements

- Q: What material is suitable for sliding bearings?

- 2. copper powder layer 0.20~0.35mm, with good bearing capacity and wear resistance, good thermal conductivity, can timely transfer the heat generated during the operation of bearings. The composite can be infiltrated into the gap of copper powder balls, and the bonding strength is improved.

- Q: What are the components of plain bearings?

- 2 pairs of open radial sliding bearings (bearing housings, bearing caps, stud screws, threaded holes, oil holes, oil tanks, split bearings)

- Q: What are the factors associated with the oil film pressure of dynamic sliding bearings?

- 1) a convergent wedge gap must be formed between the two surfaces that are relatively sliding

- Q: Now the self-lubricating sliding bearings can withstand the high speed, and if the speed is 30000 rpm, what kind of sliding bearings are chosen?

- Price a penny, goods, good price more expensive, Germany's good

- Q: What are the main applications of plain bearings?

- Plain bearings are mainly used in:Automobiles, motorcycles, hydraulic machinery,Metallurgical machinery, forging machinery, oil field machinery,Construction machinery, mining machinery, power facilities, etc.

- Q: Bearing bearing belongs to what type of

- The Bush may also be burnt due to excessive load, high temperature, impurities or abnormal viscosity of lubricating oil. The plain bearing is damaged after burning the tile.The bearing load in the bearing is composed of sliding bearings, so called single sliding bearing them there is no difference, as Bush is concerned, in order to reduce friction and wear, so use copper alloy, copper base aluminum tin alloy, tin alloy, Babbitt and so on, they are not standard

Send your message to us

Bearing Bearings 7017 Angular contact ball bearings 7017 Angular contact ball bearing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords