HSS Steel Round Bar/High Alloy Round Tool Steel Bar/M2/M25M42/D2/H13

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 33 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of steel round bar:

Characteristic:Tungsten-molybdenum high speed steel developed by China,high performance in toughness ,hardness, high temperature hardness.

Festures of steel round bar:

Anneal temperature: 840-860

Relief annealing temperature: 720-760

Hardening temperature: 1210-1230

Hardening medium: salt bath under 600,aslo use oil cooling or air cooling

Normal temper temperation: 540-560 RC Rockwell Hardness after hardening and temperature: 63-66

Production Capacity: 1000 Tons/Month

Tech:EAF+LF+VD+ESR

High strength at elevated temperatures

Specifications of steel round bar:

| C | Si | Mn | W | Mo | Cr | V | P | S |

| 0.80-0.90 | 0.20-0.45 | 0.15-0.40 | 5.50-6.75 | 4.50-5.50 | 3.80-4.40 | 1.75-2.20 | ≤0.030 | ≤0.030 |

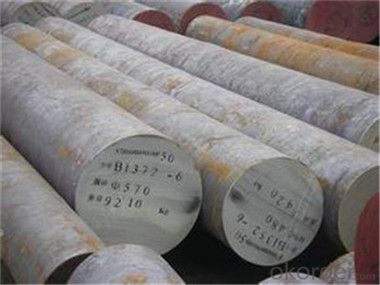

Images of steel round bar:

FAQ:

1. What is your package?

Packing situation: standard seaworthy packing or as customer required.

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q: What are the environmental considerations of steel round bars?

- Steel round bars have several environmental considerations. Firstly, the production of steel involves the extraction of iron ore, which can have negative impacts on ecosystems and habitats. The mining process can lead to deforestation, soil erosion, and the release of harmful pollutants into the air and water. Additionally, the manufacturing of steel round bars requires a significant amount of energy, which often comes from non-renewable sources such as coal and natural gas. The burning of fossil fuels for energy contributes to greenhouse gas emissions and climate change. The steel industry is one of the largest emitters of carbon dioxide globally. Furthermore, the transportation of steel round bars can also have environmental consequences. The long-distance shipping of steel products contributes to carbon emissions and air pollution. This is especially significant when steel is imported or exported over large distances. However, it is important to note that steel is a highly recyclable material. Recycling steel reduces the need for new production, conserves energy, and decreases the environmental impacts associated with mining and extraction. By choosing steel round bars made from recycled steel, individuals and industries can contribute to a more sustainable and environmentally-friendly approach. Overall, the environmental considerations of steel round bars include the impacts of mining and extraction, energy consumption during production, and transportation emissions. However, the recyclability of steel offers an opportunity to minimize these environmental impacts and promote a more sustainable steel industry.

- Q: Are steel round bars prone to fatigue failure?

- Yes, steel round bars are generally prone to fatigue failure due to cyclic loading and repeated stress, especially when exposed to high loads or stress concentrations. However, factors such as material quality, design, and proper maintenance can help mitigate the risk of fatigue failure.

- Q: Can steel round bars be used in the production of agricultural machinery?

- Yes, steel round bars can be used in the production of agricultural machinery. Steel round bars are commonly used in the manufacturing of various components and parts for agricultural machinery due to their strength, durability, and versatility. These bars can be used to construct essential parts such as axles, shafts, gears, and brackets that are required for the operation of agricultural machinery. Additionally, steel round bars can be easily machined and welded to meet specific design requirements, making them a suitable choice for agricultural machinery manufacturers.

- Q: How do steel round bars perform under static or stationary loads?

- Steel round bars perform exceptionally well under static or stationary loads. Due to their high tensile and compressive strength, they can withstand heavy loads without significant deformation or failure. The structural integrity and stability of steel round bars make them a reliable choice for various applications where static or stationary loads are involved.

- Q: How do steel round bars compare to aluminum or steel tubing?

- Steel round bars, aluminum tubing, and steel tubing all have their own unique properties and applications, so it is important to understand the characteristics of each material before making a comparison. Steel round bars are solid cylindrical bars made of steel. They are known for their high strength and durability, making them suitable for heavy-duty applications. Steel round bars have excellent tensile strength and can withstand high levels of stress and pressure. They are often used in construction, manufacturing, and engineering projects where strength and structural integrity are crucial. Steel round bars are also highly resistant to corrosion, making them suitable for outdoor and marine applications. Aluminum tubing, on the other hand, is made from aluminum, which is a lightweight and corrosion-resistant material. Aluminum tubing is known for its excellent thermal conductivity and electrical conductivity. It is often used in applications where weight reduction is important, such as in the aerospace and automotive industries. Aluminum tubing is also commonly used in the construction of heat exchangers and in electrical wiring systems due to its conductivity properties. Steel tubing, similar to steel round bars, is made of steel but is hollow in shape. Steel tubing is known for its versatility and wide range of applications. It is available in various shapes and sizes, including round, square, and rectangular, allowing for different structural designs. Steel tubing is often used in construction, automotive manufacturing, and industrial applications. It offers high strength and rigidity, making it suitable for applications that require structural support or the ability to withstand heavy loads. In comparison, steel round bars offer superior strength and durability compared to aluminum and steel tubing. They are ideal for heavy-duty applications that require high levels of strength and structural integrity. However, steel round bars can be heavier and more expensive than aluminum tubing, which is often preferred for lightweight applications. Steel tubing, on the other hand, provides versatility in terms of shape and size, allowing for more design options. Ultimately, the choice between steel round bars, aluminum tubing, and steel tubing depends on the specific requirements of the application, including factors such as strength, weight, cost, and corrosion resistance. It is important to carefully evaluate these factors and consult with experts to determine the most suitable material for a particular project.

- Q: How do steel round bars compare to other types of steel products?

- Steel round bars have several advantages over other types of steel products. Firstly, their cylindrical shape makes them highly versatile and easy to work with, allowing for various applications in construction, manufacturing, and engineering. Secondly, round bars have superior strength and durability, making them ideal for load-bearing structures and heavy-duty machinery. Additionally, their uniformity and smooth surface facilitate precision machining and fabrication processes. Lastly, steel round bars offer excellent resistance to corrosion and wear, ensuring a longer lifespan compared to other steel products. Overall, their unique properties and versatility make steel round bars a preferred choice for many industries.

- Q: How do you calculate the weight of a steel round bar based on its density and dimensions?

- To calculate the weight of a steel round bar, you need to multiply its density by its volume. The volume of a round bar can be calculated using the formula V = πr^2h, where r is the radius and h is the height. Once you have the volume, simply multiply it by the density of the steel to get the weight.

- Q: Can steel round bars be used in the manufacturing of jewelry?

- Yes, steel round bars can be used in the manufacturing of jewelry. While steel is not as commonly used as precious metals like gold or silver in jewelry making, it can still be utilized to create unique and industrial-inspired pieces. Steel round bars offer a sleek and modern aesthetic, making them suitable for contemporary or minimalistic designs. Additionally, steel is known for its durability and strength, ensuring that the jewelry will withstand everyday wear and tear. However, it is important to note that steel may not be suitable for individuals with metal allergies or sensitive skin.

- Q: Are steel round bars resistant to impact?

- Yes, steel round bars are generally resistant to impact due to their high strength and durability. They can withstand significant force without deforming or breaking, making them suitable for applications where impact resistance is required.

- Q: What is the composition of steel round bars?

- Steel round bars primarily consist of iron and carbon, along with small amounts of other elements like manganese, silicon, sulfur, and phosphorus. The primary element, iron, provides the steel bar with strength and structural integrity. The carbon content is vital in determining the bar's hardness and strength, where higher carbon levels result in a harder and stronger material. Manganese contributes to the overall strength and toughness of the steel, while silicon aids in enhancing its resistance to oxidation and scaling at high temperatures. Sulfur and phosphorus, considered impurities, are kept at low levels to prevent any negative impact on the mechanical properties of the material. In summary, the composition of steel round bars is meticulously controlled to achieve the desired strength, durability, and specific properties required for different applications.

Send your message to us

HSS Steel Round Bar/High Alloy Round Tool Steel Bar/M2/M25M42/D2/H13

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 33 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords