HRCV SLEWING BLOCK, SLEWING CONTROL DEVICE FOR TOWER CRANE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1 Characteristic

HRCV slewing controller is a hoisting slewing controller developed by our company according to service condition of customer.

The main technical feature as follows:

(1) This product combined the controller and thyristor module,the connection of the users is simple and easy.Prevent the damage of the controller and thyristor module caused by mis-wiring of the customer.

(2) Realize the best optimization of AC voltage control curve and DC voltage control curve.

(3) With the function of inching during operation, realize the accuracy.

(4) The electronic components adopt the imported industrial grade chip, on the control panel directly with power supply and direction indicator light.

(5) Adopt the coating treatment on the printed circuit board,enhance the dust prevention and anti-condensation capacity of the circuit board.

2 Operation condition

(1) Application of environment condition

working temperature: -10 °C~ + 40 °C

relative humiduty: maximum 50% (when the temperature is 40 °C)

maximum 95% (when the temperature is 20 °C)

(2) Grid quality

voltage continuously fluctuate no more than ±10%

(3) Rated voltage

50HZ/60HZ, AC380V/440V three-phase voltage

50HZ/60HZ, AC48V/55V voltage by one phase

3 Output parameter

(1) voltage output

three-phase voltage output: 50HZ AC140V~380V;

eddy current voltage: DCOV~20V

(2) electricity output

according to the size of the rotary engine,electricity output choose 106A,162A,273A and so on.

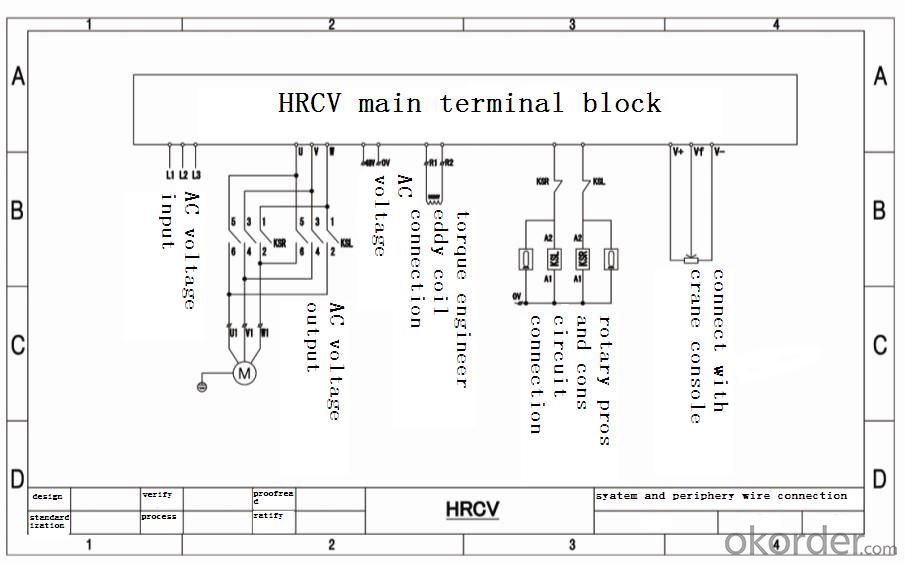

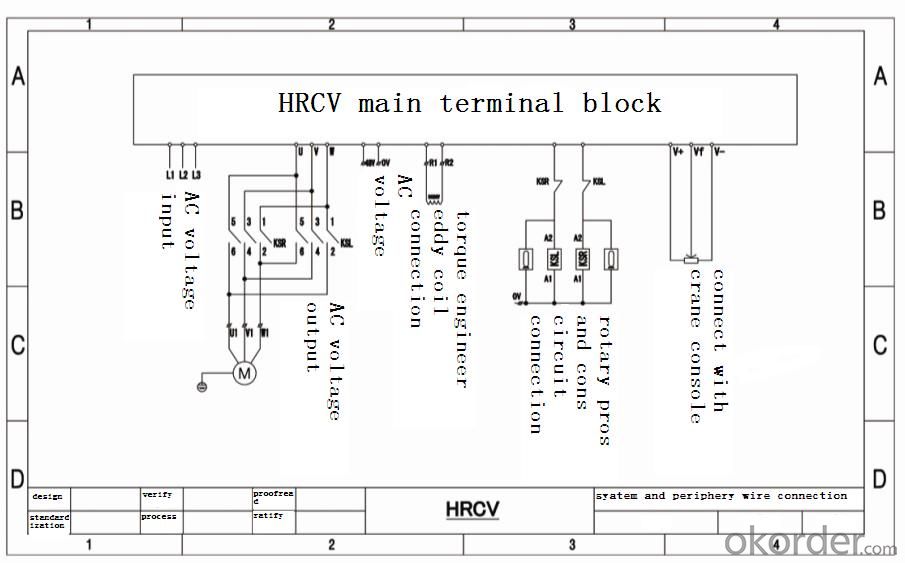

4 HRCV slewing controller wire connection sketch map

- Q: What are the mixing arms of the concrete mixer?

- Mixing arm concrete mixer is a component of the mixing arm itself and divided into lateral mixing arm (positive and negative points), stirring arm (also have positive and negative points), stirring arm below is the bearing seat connected, connected with 4 sets of high strength bolts with stirring arm. The top is equipped with wear-resistant mixing blades, connecting with mixing blades, high-strength bolts 2 sets. In addition, some manufacturers have designed mixing side bonded shaft swivel, is installed in the interval between the stirring arm fixed and rotated in two ways.

- Q: Changsha Sanlian Building Machinery Fittings Factory

- In addition, you can check the input path, or the name of the unit on the map. It will remind you that there is no unit in Changsha and no way. In addition, we received a fax, saying that you want to order what goods, may wish to go to the other party's local industrial and commercial Red Shield network to check whether there is this unit

- Q: What is equipment manufacturing and machinery manufacturing? What's the difference between them?

- Equipment manufacturing, also known as equipment industry, mainly refers to the capital goods manufacturing industry, is to meet the needs of the development of the national economy departments and national security needs and manufacture all kinds of technical equipment industry collectively. According to the national economy sector, its range of products including investment manufactured goods machinery electronics and ordnance industry, belonging to the metal products industry, general equipment manufacturing industry, special equipment manufacturing, transportation equipment manufacturing, electrical equipment and equipment manufacturing industry, electronics and communications equipment manufacturing, instrumentation and cultural office the equipment manufacturing industry in the 7 major categories of 185 kinds.

- Q: What are the principles, performances and uses of the commonly used construction machinery equipment?

- 1.: concrete pump principle: concrete pump driven by motor pump system, the conveying capacity of constant power control of hydraulic system of concrete pump automatic control, manual control can also be used to select the concrete delivery volume. Performance: 1. using the hydraulic system of double pump double open circuit, the main pump valve swing circuit and S circuit are separate for fault diagnosis and removal; 2. pumping hydraulic circuit adopts the main valve pilot pressure control; 3. hydraulic system has safe relief protection, while the main pumping system overpressure, oil pump automatic pressure cutting off; 4. switching circuit with constant voltage supply with the energy storage device, so as to guarantee reliable swayingforce large and have the advantages of energy saving effect; 5. pumps and valves are used continuously, the world famous brand is more reasonable and more reliable and easily realized commodity concrete transport quantity adjustment; 6. hydraulic pipeline with cone seal pipe joint sealing material; 7. pumping circuit adopts a valve block mode of high and low voltage switch, convenient, no leakage; 8. with oil and oil filter technology, foreign body into the hydraulic system. Further improve the hydraulic system reliability and component life; 9. hydraulic hose hose. Use: widely used in commercial concrete demand for large, high grade and strict quality requirements, long conveying distance of high-rise buildings, municipal construction, electric power, energy, transportation and other civil and industrial buildings, especially the construction of the narrow space more show its true colour of a hero.

- Q: What measures can effectively reduce the construction accident rate?

- Hefei construction workers training _ fail safe design: in the part of the system, equipment malfunction or damage, can also ensure the safety of safety and technical measures known as fault - Safety Design in a certain period of time (fail-safe). Generally speaking, through careful technical design, the system and equipment are in a low energy state when the fault occurs, thus preventing the unexpected release of energy. For example, a fuse in an electrical system is a typical fault - Safety Design; when the system is overloaded, the fuse is fused and the circuit is disconnected to ensure safety. Although the fail safe design is an effective measure of safe technology, but considering the fail safe design itself may not work due to failure, so the choice of safety technical measures should not give priority to the use of.

- Q: Where are the mechanical pressurization air supply facilities set up?

- When the smoke proof staircase and antechamber antechamber, fire elevator or common antechamber parts can be opened outside the window, can use the natural ventilation, resulting in a stairwell with or common antechamber in the use of natural smoke exhaust with pressurized air supply arrangement of diversified combinations, and the two exhaust can not be shared.

- Q: What is a door rack for a construction site? How high is it generally?

- This depends on the erection of the height of the general 3 steps and within 5-6 yuan a meter, assuming the erection of 4.5 meters high, 22.5-27 yuan a square. This is calculated in accordance with single-layer, the higher the more expensive, 9 meters in 65 yuan or so square. In accordance with the establishment of meters, in accordance with the erection of the volume of the calculation.

- Q: Where are the hanging baskets for the building?

- It is strictly prohibited to use hanging baskets as vertical transport facilities for personnel and materials; no staff member is allowed to climb from a basket to a B basket

- Q: What are the sub projects of a construction project?

- Lime soil, sand and gravel foundation, geosynthetics foundation, fly ash foundation, dynamic compaction, foundation grouting, preloading foundation, vibroflotation foundation, jet grouting foundation, cement mixing pile foundation, soil and lime soil compaction pile foundation, cement fly ash gravel pile, cement soil pile foundation. Based on sand pile foundation

- Q: What is the difference and connection between equipment manufacturing and machine building?

- In accordance with the standards of classification, including metal products, general machinery manufacturing, machinery manufacturing, transportation equipment manufacturing, electronic and communication equipment manufacturing industry, electrical machinery and equipment manufacturing, instrumentation and office machinery manufacturing seven deducted 186 small consumer related manufacturing industry after class. Equivalent to the European countries referred to as "capital goods manufacturing", that is, we often say "the production of means of production industry."".

Send your message to us

HRCV SLEWING BLOCK, SLEWING CONTROL DEVICE FOR TOWER CRANE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords