HR Carbon etc Hot Rolled Steel with Standard Q235 Q345 SS400

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot rolled steel Description:

Rolled to its final dimensions while it’s hot enough to scale, our hot-rolled steel is an amalgamation of the various qualities of steel. It can be in the form of plates, sheets and coils. Our hot rolled steel sheets and coils are applied to wide range of uses such as automobile, electrical appliance, machinery manufacturing, container manufacturing, shipbuilding bridge, pipeline, and receive high acclaim from our customers for its excellent quality.

Quick Details

Standard:AISI, ASTM, BS, DIN, GB, JIS

Grade:hot rolled

Thickness:2mm-60mm

Model number:Q195-Q235-Q345

Type:steel coil

Technique:Hot Rolled

Surface Treatment:Can provide galvanized

Application:Flange Plate

Special Use:Wear Resistant Steel

Width:1000-1800mm

Length:Coil or cliens requirements

Packaging & Delivery

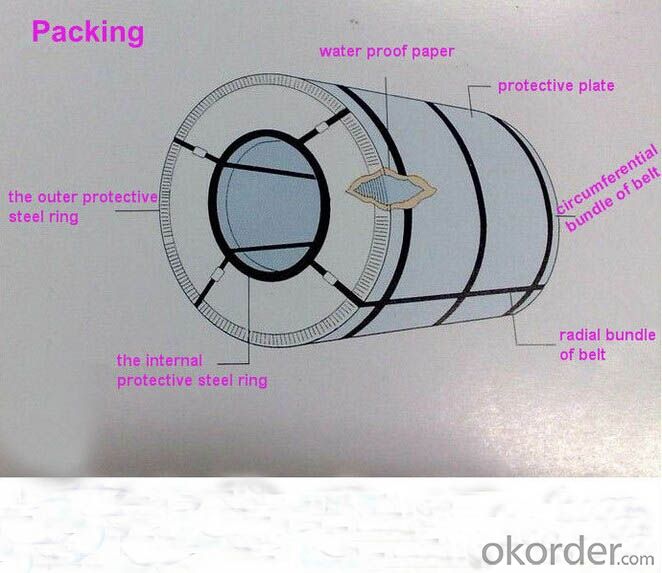

Packaging:standard sea export packing, or we can also package according to the customers' requirments

Delivery Detail:about 20 working days

Specifications

| Commodity | Hot rolled steel Coil |

| Thickness | 2.0-60mm |

| Width | 1000-1800mm |

| Material | Q195-Q235-Q345 |

| One Coil weight | About 20 tons |

| Surface treatment | Oiled or unoiled as the requirement |

| Packing | Seaworthy packing, each coil packed hot rolled steel strip, put 1 or more coils in one pallet, then packed with plastic membrane, then packed with pp bags (inside the bag is plastic membrane), last protect the corner with hot rolled steel strip. |

| Supply ability | 6000 ton per month |

| Delivery time | 10-25 days |

| Application | Roof, outer walls, ovens, lined plastic window, light steel keel. |

FAQ:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4.What is the validity of your quotation?

Normally 7 days.

5.What is your advantage?

24 hour quick response /Customer oriented/ Credit foremost/ Top quality Excellent

- Q: What are the different types of steel coils available?

- There are several different types of steel coils available, each with its own specific properties and uses. 1. Hot Rolled Steel Coils: These coils are produced at high temperatures and are commonly used in applications that require a smooth and polished finish, such as automotive parts, construction materials, and machinery. 2. Cold Rolled Steel Coils: These coils are processed at lower temperatures to improve the surface finish and dimensional accuracy. They are widely used in industries such as automotive, appliances, and electronics, where a high level of precision is required. 3. Galvanized Steel Coils: These coils are coated with a layer of zinc to protect the underlying steel from corrosion. They are commonly used in construction materials, roofing, and automotive parts that are exposed to harsh environmental conditions. 4. Stainless Steel Coils: These coils are made from a combination of iron, chromium, and other elements to provide excellent corrosion resistance and high strength. They are widely used in applications that require hygiene, such as food processing equipment, medical instruments, and kitchen appliances. 5. Electrical Steel Coils: These coils are specifically designed for applications that require magnetic properties, such as transformers, electric motors, and generators. They have low core losses and high permeability to efficiently transfer electrical energy. 6. Pre-painted Steel Coils: These coils are coated with a layer of paint or other protective coatings to enhance their aesthetic appeal and provide additional protection against corrosion. They are commonly used in the construction industry for cladding, roofing, and siding. 7. Tinplate Steel Coils: These coils are coated with a thin layer of tin to prevent corrosion and provide a barrier against moisture and oxygen. They are widely used in the packaging industry for cans, containers, and other food or beverage packaging. These are just a few examples of the different types of steel coils available in the market. Each type has its own unique properties and applications, making them suitable for various industries and purposes.

- Q: in a lab at school we did heat treatment of steelwhat are the possible phases present in the steel sample in as-received, as-quenched and as-tempered conditions? specifically when is it ferrite, austenite and pearliteis the steel originally in the ferrite phase? then when headed turns into austenite and when quenched martensite is formed and when tempered cermentite is formed...........where is pearlite involved and am i correct about the ferrite?

- hey from what i learned in uni last sem, steel is originally ferrite form at first at room conditions. it will undergo poly morphic transformation to become FCC structure austenite form at 912 degree celcius. under conditions, it can become pearlite (which is a combination of ferrite and cementite) or bainitie( a finer form of pearlite). queching conditions to room temperature will form martensite which is the strongest but brittle steel form. tempered cementite is formed when we quench it and then raise temperatures before sir cooling. hope it helps, pls vote me best answer is i deserve it. thanks

- Q: What is the average cost of shipping steel coils?

- The average cost of shipping steel coils can vary depending on various factors such as the distance, weight, dimensions, and shipping method. It would be best to contact shipping companies or freight forwarders for accurate and up-to-date pricing information.

- Q: What are the different types of steel coil finishing machines?

- There are several different types of steel coil finishing machines, including slitting machines, cut-to-length machines, and coil coating machines. Slitting machines are used to cut steel coils into narrower strips, while cut-to-length machines are used to cut steel coils into specific lengths. Coil coating machines are used to apply a protective coating or finish to the surface of steel coils.

- Q: How are steel coils inspected for surface finish variations?

- Steel coils are inspected for surface finish variations using visual examination, mechanical methods such as gauges and calipers, and non-destructive testing techniques like magnetic particle inspection or ultrasonic testing.

- Q: How are steel coils inspected for paint adhesion?

- Various methods and techniques are utilized to inspect the adhesion of paint on steel coils. One commonly employed method is the tape test, which involves pressing adhesive tape onto the painted surface and swiftly removing it. The amount of paint that is lifted off by the tape is then examined to assess the adhesion. If the paint adheres well to the steel, only a minimal amount of paint will be removed. Another method employed is the crosshatch adhesion test. This test entails making parallel cuts on the painted surface using a sharp blade, creating a crosshatch pattern. A piece of adhesive tape is then applied over the cuts and rapidly pulled off. The evaluation of the paint that is removed from the crosshatched area determines the adhesion. Furthermore, a visual inspection is frequently conducted to evaluate the overall appearance and adhesion of the paint. Inspectors search for any indications of cracking, peeling, or bubbling, which may indicate poor adhesion. They also check for any areas where the paint may have chipped or flaked off. Moreover, various laboratory tests can be conducted to assess the paint adhesion on steel coils. These tests may include techniques like the pull-off test, where a specialized device is used to measure the force required to remove a small section of the paint from the surface. Other tests may involve subjecting the painted surface to extreme temperature or humidity conditions to assess the paint's performance under different environmental factors. In summary, a combination of visual inspections, tape tests, crosshatch adhesion tests, and laboratory tests are employed to thoroughly inspect steel coils for paint adhesion. These tests ensure that the paint adheres effectively to the steel surface, resulting in a durable and long-lasting finish.

- Q: How are steel coils inspected for quality assurance?

- Steel coils are inspected for quality assurance through a rigorous process that involves various tests and checks. Firstly, visual inspection is conducted to look for any surface defects such as scratches, dents, or rust. This ensures that the coils are in good condition and free from any obvious flaws. Next, dimensional inspection is performed to verify the dimensions and tolerances of the coils. This involves measuring the width, thickness, and length of the coils to ensure they meet the specified requirements. Any deviations from the standard dimensions are noted and addressed. Additionally, mechanical testing is carried out to assess the strength and durability of the steel coils. This includes conducting tensile tests to measure the strength and elasticity of the steel, as well as impact tests to evaluate its ability to withstand sudden loads or shocks. Furthermore, chemical analysis is conducted to determine the composition and purity of the steel. This involves taking samples from the coils and analyzing them in a laboratory to check for the presence of any impurities or elements that may affect the quality of the steel. To ensure the coils meet specific industry standards, non-destructive testing methods such as ultrasonic testing or magnetic particle inspection may be employed. These techniques allow for the detection of internal defects or irregularities that may not be visible to the naked eye. In addition to these tests, the coils may undergo surface treatment inspections, such as galvanization or coating checks, to ensure the protective layers are applied correctly and meet the required specifications. Overall, steel coil inspection for quality assurance involves a combination of visual, dimensional, mechanical, chemical, and non-destructive testing methods. These comprehensive inspections help to ensure that the steel coils meet the necessary quality standards and are suitable for their intended applications.

- Q: How are steel coils used in the production of steel framing systems?

- Steel coils are used in the production of steel framing systems as they are the primary raw material. These coils are unwound and fed into a roll forming machine, where they are shaped into the desired profiles and lengths. The steel framing systems, including studs, tracks, and joists, are then fabricated from these formed coils, providing structural support and stability to buildings and structures.

- Q: my homework is a breif description on steel pipe. for plumbing/gas.please help me i dont have a clue where to start, something about the thread and where its used.Thanks,

- Here are a few quick things for you to check into on your own. First, there are a wide variety of materials that pipes can be made from such as carbon steel, stainless steel, aluminum, etc. Second, pipes can be of welded construction or seamless. Sometimes seamless pipes are called DOM (drawn over mandrel). Third, with the types of each pipe are a variety of grades. For example, steel pipe can be listed as A53, A106, A500, A513, etc. Each one of these grades has a different application because of their chemical composition and method of manufacture which effects its strength. Fourth, there is a difference between a 4 pipe and a 4 tube. Last, pipes for fluids are typically threaded with NPT threads. These threads are tapered so that as the pipes are screwed together they become tighter and therefore leak proof. I probably over complicated things but I hope this helped you. Good luck.

- Q: What are the environmental and social impacts of mining, processing and using steel?

- I don't think society as we know it could exist without it. As for the enviroment there is damage from mining, processing and from using steel equiptment.

Send your message to us

HR Carbon etc Hot Rolled Steel with Standard Q235 Q345 SS400

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords