hot sale Suspension Platform Model:ZLP300

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 200 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

TRUEMAX was established in 2003 at Hangzhou, China. In the past 10 years, TRUEMAX has established over 10 manufacturing base, to offer the one-stop services in construction machinery filed, including R&D, designing, manufacturing, quality control and delivery.

With core principle of “True to Quality, Ture to Customer”, our product has been exported to more than 100 countries with high customer appreciation & brand popularity.

TRUEMAX provide the full series of construction machinery and one-stop overall solution. Our product range covers pre-fabrication including aggregate crushing, dedusting and block making; concrete series including mixing, batching, pumping & placing; construction series, such as tower crane, building hoist, suspension platform and lifting basket; light construction machinery, including compacting, cutting, surface finishing machines & rebar processing machines.

Especially the concrete placing boom, we’re the No. 1 in term of products variety, with top quality placing boom of placing radius ranging from 10 meters to 51 meters over 10 different series, the excellent quality & performance has been tested & approved by being used in lots of world famous high buildings.

The manufacturing base of TRUEMAX adopts 6S management system. Quality control system are implemented strictly in the whole procedures, including components purchasing, fabricating and manufacturing, packing and dispatch pre-inspection, ensuring the perfect quality assurance for all of our products. With international certificates like ISO9001:2008, CE & SGS, TRUEMAX guarantee the international first-class level for all of our products.

At present, TRUEMAX is the“Grade A Export Enterprise of China Customs”, “Famous Export Brand of Zhejiang”, “ Famous Export Brand of Hangzhou”, “High & New Technology Enterprise of Hangzhou”, “Top 100 innovation-type foreign trade enterprise of Hangzhou”&“ Key enterprises of Xiacheng district, Hangzhou”, with support from Zhejiang Public Foreign Trade Service Platforms consecutively in 2012 and 2013.

“Quality achieves outstanding success, innovation leads the bright future”, our working principle has leads the rapid expansion of TRUEMAX, with branches and spare parts distribution centers established oversea step by step. We’re targeting to complete the global layout of TRUEMAX Agent within next 2 years, and “TRUEMAX 6S” stores within 5years.

In the coming days, TRUMAX will continue to forge ahead, make our best efforts to create the best platform for career performance, as well as to realize the maximized mutual benefit with all TUREMAX friends, partners, agents & clients.

“View Broad, Ambitions Boundless”, at a new height, we wish to join hands with all the ambitious friends together, contributing to the consummation of the first-class quality construction machinery industry, and creating the new glory constantly

Due to credible quality, supreme after–sale service, reasonable price, and esthetic appearance, we have established a long term business and technical cooperation relationship with customers all over the world.

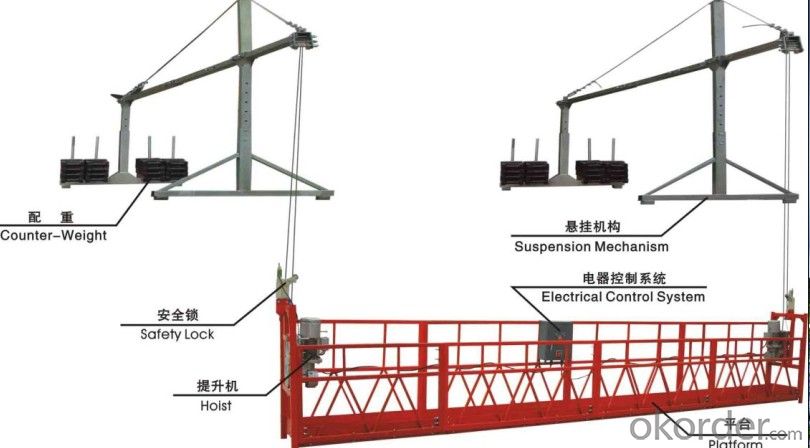

1)The length of platform can be adjusted within 1m-7.5m.

2)The working height can be adjusted within 1m-200m.

3)The Voltage can be adjusted with your need: 220V/380V/415V/440V, etc.

- Q: Who has a good way to clean the basket and the basket?

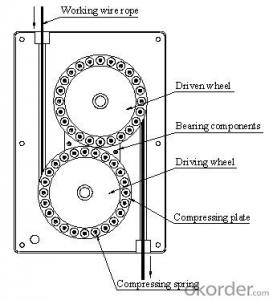

- 1, timely removal of electric basket, hoist table full and dirt on the work wire rope, to avoid lifting machine into, out of the mouth, into the debris, damage to the machine parts. Note that there is no sound or smell, after work cover, to avoid rain, debris and other intrusion. Avoid collision during installation, transportation and use so as to avoid damage to the casing.

- Q: What issues should I pay attention to when removing the galvanized basket?

- 1, before the demolition of the basket to conduct a comprehensive inspection, record damage. 2. Park the platform on the flat ground and remove the rope and tie down the iron. 3, the power cut off Lida electric basket.

- Q: Construction plan for mounting basket on steel pipe support frame

- (3) the front and rear beams are respectively arranged before and after stent insertion within the casing, with the beam to the front and rear beams set, and according to the situation before the selected overhanging beam, the distance between the front and rear supports should be put to the maximum, will be placed on the front seat pillar rod sleeve. The small connecting sleeve is arranged on the inserting rod sleeve of the back support, and is fixed by bolts, and the bracket is assembled and completed.

- Q: Construction basket operation certificate is not able to operate?

- 6, support should be used before the lifter and platform is connected firmly, the safety rope and the safety lock connection is reliable, the action is normal, the suspension wire node is reliable, the connecting bolt, pin is loose, the suspension mechanism of the node and the wire rope weight is normal and reliable and various limiting device is sensitive and reliable to check and acceptance, and to strengthen the daily inspection, repair and maintenance.

- Q: How are the baskets assembled?

- 2, installation sequence: first, according to "basket construction program" on-site measurement, verify the installation position of the basket. The upper part of the bracket, the gantry crane basket counterweight, wire rope is transported to the roof installation position of the basket body, lifting machine is transported to the corresponding ground installation position. Assemble the upper support and the basket. Release wire rope, cable and safety rope. Switch on the power. The steel wire rope wear. The lifting basket. The debugging and check the basket. 9 installation acceptance

- Q: Request a basket construction quota

- The use of construction basket wall repair and brushing the wall paint, how to calculate the cost of measures (experts). According to the actual situation, the selected quotations, such as scaffolding construction, construction measures should apply scaffolding quota items. Such as hanging basket construction, it should be calculated by the use of basket construction measures

- Q: How to grasp the proper use of basket

- The first point is must pay attention to grasp the good plan targeted and feasibility, can not speak generally, should be based on the specific construction scheme, the use of a good grasp of the building to building basket, the basket cover the entire face, do not stay dead, so as to guarantee the safety of.

- Q: How to transplant basket?

- If it is new, then add the soil in the new pot, and then cut down the plant and plug it on the surface of the new soil, pay attention to it!! The soil can not be over the heart. Just water it. No matter what kind of transplant, it's the same thing

- Q: What are the lifting modes of the electric gondola?

- Lifting machines have different lifting methods and different installation positions, so the two hoists have two different mounting processes. Hoist hoist is installed at the top of the building lift, give up the arm instead of pulley operation, all lifting is controlled by the roof of the control personnel

- Q: What are the specifications associated with the gondola?

- In winter fog construction, should wait for fog to disperse, and in the sunshine is more abundant, can use electric hanging basket, otherwise, prone to wire rope slip, and may occur equipment accident.

Send your message to us

hot sale Suspension Platform Model:ZLP300

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 200 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords