Hot sale seamless steel pipe with best price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

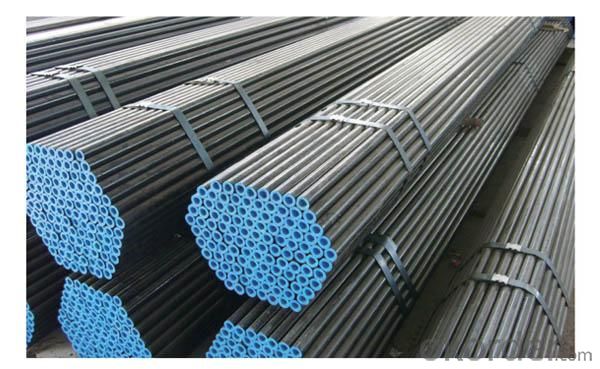

1、Structure of Hot sale seamless steel pipe:

carbon seamless steel pipes are widely used in gas, water and oil, transpotation;constructions;Bridge,highway,windows of model steel door; building materials;fences;heating facilities Fluid Pipe;conduit pipe,scaffolding pipe.etc.

2、Main Features of Hot sale seamless steel pipe:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

3、Hot sale seamless steel pipe Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4) Surface:black lacquered,varnish coating or galvanized.

5) Ends:Beveled or square cut,plastic capped,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Hot sale seamless steel pipe:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

6、Hot sale seamless steel pipe Images:

- Q: What are the different types of supports used for aboveground steel pipes?

- There are several types of supports commonly used for aboveground steel pipes, including pipe hangers, pipe clamps, pipe saddles, and pipe shoes. These supports are designed to provide stability and prevent excessive movement or vibration of the pipes, ensuring their proper alignment and preventing damage.

- Q: The difference between 12Cr1MoVG alloy steel tube and 15CrMo

- 15CrMo is a steel Pearlite Heat-resistant steel, has high heat resistance at high temperature (b = 440MPa) and antioxidant activity, and has certain ability of anti hydrogen corrosion. Because of the high content of Cr, C and other alloy elements in steel, the tendency of hardening of steel is obvious, and the weldability is poor.

- Q: How to establish a concrete-filled steel tubular column model in ANSYS?

- A two unit model or a composite unit model can be adoptedTwo units are constructed of steel tubes and concreteA composite unit may be either a fiber element or a section conversion attribute

- Q: What connections are there for concrete filled steel tubular column foundations?

- Application of double beam connection node usually uses "I" shape columns and steel bracket which is around the construction technology of a modern steel concrete column girder casting formed in the steel pipe outside through the two structures, the bearing pin four axis and four angles on the common components of stress transfer. The construction technology in the application is usually used at both ends of the stress transfer construction mode, through the four steel bracket to the corresponding shear stress, avoid crack width because the node contact produces clear, delayed cracks, improve anti cracking ability of regional nodes.This node model in the connection when the longitudinal reinforcement without through the tube, without bending the construction can be carried out directly, with easy construction technology, construction control difficulty, the economic benefits of construction at the same time, the advantage of low reinforcement to save. In this joint engineering technology, the key pride is to control the stress transfer of steel bracket.

- Q: Seamless steel tube 89X4 meters, how heavy?

- According to the theory, each meter is 8.3844 kilograms. If you want to be precise, you'll lose your own weight.

- Q: What are the uses of seamless steel tubes?

- A large number of pipes used for conveying fluids, such as pipelines for transporting petroleum, natural gas, gas, water, and certain solid materials.

- Q: What are the common sizes of steel pipe fittings?

- Depending on the particular application and industry regulations, the sizes of steel pipe fittings can vary. Nevertheless, there are numerous standard sizes that are commonly utilized in various industries. These sizes encompass a range from ¼ inch to 48 inches in diameter. Among the most frequently used sizes are ½ inch, ¾ inch, 1 inch, 1 ¼ inch, 1 ½ inch, 2 inch, 2 ½ inch, 3 inch, 4 inch, 6 inch, 8 inch, 10 inch, 12 inch, 14 inch, 16 inch, 18 inch, 20 inch, 24 inch, 30 inch, 36 inch, 42 inch, and 48 inch. These sizes are often obtainable in different lengths to accommodate diverse installation requirements. To determine the appropriate size of steel pipe fittings for a specific project, it is crucial to refer to industry standards and specifications.

- Q: Can steel pipes be used for irrigation pumps?

- Yes, steel pipes can be used for irrigation pumps. Steel pipes are commonly used in irrigation systems due to their durability, strength, and resistance to corrosion. They can handle the high pressures and flow rates required for efficient irrigation, making them a suitable choice for connecting and transporting water from irrigation pumps.

- Q: What quota is reserved for buried DN20 steel pipe?

- It is an embedded sleeve control sub item, if the reserved hole, then there is no need to cover, special subject structure adjustment factor of the cost of the water supply and drainage engineering, water supply and drainage engineering he is buried under the charge.

- Q: How are steel pipes repaired if they develop leaks?

- Steel pipes can be repaired if they develop leaks through various methods such as welding, clamping, or using epoxy compounds. The specific repair technique depends on the size and location of the leak as well as the type of pipe, and it is typically carried out by trained professionals with the necessary equipment and expertise.

Send your message to us

Hot sale seamless steel pipe with best price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords