Hot Sale! Aluminum Colored Roof Tile Making Machine Made in China

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

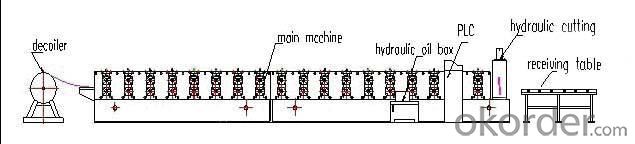

Main parameters of Aluminum Colored Roof Tile Making Machine Made in China

No. | main parameters of Roll Forming Machine | |

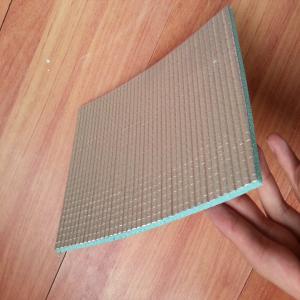

1 | Suitable to process | colored steel,galvanized plate,aluminum plate |

2 | Width of the plate | 1000mm |

3 | Roller | 16rows |

4 | Dimensions | 8500*1600*1100mm |

5 | Power | 5.5+4kw |

6 | Thickness of the plate | 0.3-0.8mm |

7 | Productivity | 8-12m/min |

8 | Material of the cutting blade | Gr12 steel,hard treatment |

9 | Diameter of the roller | Φ70mm |

10 | Weight | 6t |

11 | Voltage | 380V |

14 | Control system | PLC control |

PS: the parameters above are for reference; we produce according to customers' profile drawing.

Decoiler-----Feeding&Guiding-----Roll Forming------Hydraulic Cutting------Receiving Table

1. Shear of Aluminum Colored Roof Tile Making Machine Made in China

The cutter is controlled by hydraulic system, and the material of the blade is Gr12 steel.

- Q: What steps are required during the installation of the cement tile machine?

- Host installation: the user in accordance with the size of the foundation map dug the foundation, according to the requirements of the drawings for the foot of the embedded hole or under the embedded iron with concrete pouring, for the installation of embedded holes into the anchor bolts (M24 × 360) and then Grouting, embedded iron can be a one-time cast into the installation and direct welding with the host, based on the plane must be level, the smaller the better the better.

- Q: Analysis on the Problems of Cement Shade Machine

- bad weather; the surface of the problem will be wiped or shovel, Let the cement completely dry; coated with a layer of all-round anti-alkali color tile paint.

- Q: The processing method of the tile machine

- Mold release agent spray too little. Can be appropriate to increase the fuel injection pressure. The center of the tile plate is partial.

- Q: What are the advantages of cement tile machine?

- advanced and efficient. A new generation of equipment to add a remote control, diagnostic system, thousands of miles away on the operation of the data analysis, so that customers on the equipment maintenance easier.

Send your message to us

Hot Sale! Aluminum Colored Roof Tile Making Machine Made in China

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords