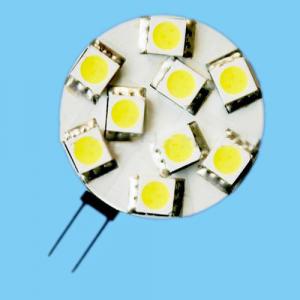

Hot Sale 1W G4 SMD LED Light With 6 Pcs Taiwan SMD5050 LED Chip

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 1000 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

SMD G4 led lamp specifications:

| Reference numbe | FT-G4-1W-S01-5050 |

| Base | GX4.0 |

| Power | 1W |

| Beam angle | 180° |

| Input voltage | 12V DC |

| LED Qty | 6pcs High Bright 5050 SMD |

| Colors | warm white, cool white |

| CRI Ra= | 70 |

| Luminance | day white 6500K: 60 LM warm white 3000K: 70 LM |

| Dimension | Φ25 mm x L41.5 mm |

| Net weight | 12g |

Feature

High-purity aluminum reflector, light housing and heat sink

High intensity tempered glass

High powerful LED light source

High efficiency imported constant current power source Architectural decorative lighting.

LED work light lamp Application:

· Landscape light, Reading lamp, Cabinet lights, Night Light, Tail light, Instrument Cluster Light, Under hood light, DashLight,

· Dome Light, License Plate Light, Reverse Light, Parking Light etc, anywhere that fits for a G4 lamp base.

Customing Options:

We support OEM/ODM

We can manufacure led lighting products by your technical data/picture/draft

Packing and delivery

Package:

Standard packing inside, cartons outside

Delivery:

Shipping Service | Estimated Delivery Time |

DHL | 2-8 business days |

FedEx | 3-8 business days |

TNT | 2-10 business days |

UPS | 1-7 business days |

EMS | 6-14 business days |

ePacket | 7-12 business days |

China Post Air Mail | 7-15 business days |

China Post SAL | 14-30 business days |

By sea | 30-40 business days |

1. 3-10 business days for Sample Orders; 7-40 business days for Bulk Orders.

2. "Business days" means Monday-Friday, excluding holidays.

3. DHL and UPS cannot ship to military or P.O. boxes address.

4. The Shipping Service above is for reference only, for any other questions, please feel free to contact us.

- Q: Indoor full color LED display module and LED what is the difference between a full color?

- (1): LED full color light emitting module display module is generally yellow green, pure green module price is more expensive; SMD full color LED display using pure green tube coreThe display module (2): LED full color pixel visual feeling is thick, low brightness, easy to have the mosaic phenomenon; patch LED full color consistent, high brightness;(3): maintenance module LED full color display is not easy to maintain, the whole module replacement cost is high; SMD full-color LED screen for easy maintenance, repair and replacement of single lamp;

- Q: What should I notice when I want to solder 1206 LED patch type luminous tube on fine copper wire?,

- It is best to use a hot-air gun heat transfer high air volume adjustable low moment welding, the specific heat jump to the appropriate place to see what you use what kind of welding wire, welding wire of different because of the different melting point impurities also some differences. The air volume is too high, easy to blow the original

- Q: How does the LED placement lamp distinguish the positive and negative poles? There is no sign on the light. Thank you

- You can also use the ohmmeter's ohmmeter. To dial multimeter, to "ohm X1" file, the light emitting diode when the red pen is connected to the positive terminal of SMD LED, the black probe is connected to the negative terminal of SMD LED.

- Q: How to detect LED SMD beads

- The output voltage of the digital clock diode file is not high, generally below 2.5V, so the measurement of LED lamp does not work, the best way is to external electrical measurement. If there are a lot of beads to measure it, can take a constant current power measurement.

- Q: Does anyone know what the current rating of a white high brightness LED patch is? Where can I find out?

- LED high power and low power, small white rated current and LED wafer, such as a chip is 20MA two 40MA.... High power 0.5W, 100-150MA, 1W, 350MA current rating in the relevant product specifications

- Q: How many volts is a single LED on the LED patch band?

- 3V or so, generally three, a group plus a resistor, power supply with 12V

- Q: What are the storage requirements of SMT patch LED (LED)?

- Keep in storage- the original sealing bag packing in the condition of the <40 C and <90% RH degrees for 12 months, more than the storage period will bake.Please check the leak before opening the packing bagIn opening the sealed bag, should be placed in SMD LED and C 60%RH. < < 30 degrees under the conditions in the above conditions, SMD LED must be in the open package using reflow within 24 hours. If placed more than 24 hours, you need to bake- baked, SMD LED in C + 80 degrees 5 degrees C and <=10%RH relative humidity in the oven for 24 hours? remove the pouch before baking, and do not open the oven door frequently

- Q: Patch LED features

- The principle of luminescence is that of cold luminescence, not by heating or discharging light, so the component life is about 50~100 times longer than that of tungsten filament bulb, and about one hundred thousand hours.

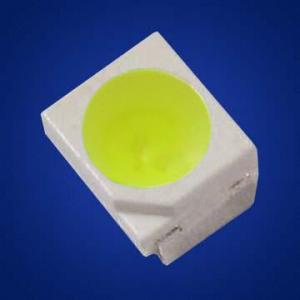

- Q: What is patch LED?

- LED is usually the lead pins form, need to be drilled on the printed circuit board, the LED pin is inserted in the hole, welded with wave soldering machine; and the patch type LED is used in welding surface, flat welded on the circuit board.

- Q: What is the difference in performance between the LED plug-in and the LED patch?

- 1, the patch is relatively easy to heat dissipation, can be directly welded on the aluminum substrate, heat faster.2, in general, there is a straw type shell, general lighting has front facing directivity, just look at it, brightness will be the biggest. The patch has a relatively wide divergence angle and is more suitable for fluorescent lamps.

Send your message to us

Hot Sale 1W G4 SMD LED Light With 6 Pcs Taiwan SMD5050 LED Chip

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 1000 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords