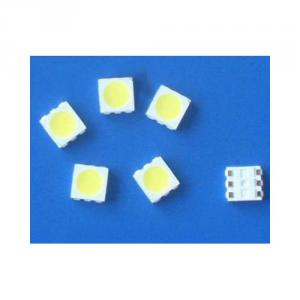

Hot Selling 1W High Power 5050 SMD Led Diode

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 1000 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features:

1.Long lifespan: Use silica gel packages, effectively improve the heat dissipation performanc, can be used than 50,000hrs.

2.High energy efficiency:save 80% power than sodium lamps.

3.Environmental friendly: no lead,no mercury and no pollution.

4.More safety:good impact resistance, no UV rays, no IR rays.

5.Quick response: achieves high lumens within in nanoseconds.

6.No flicker, no strobe for less visual fatigue.

Notes:

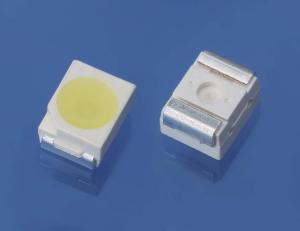

1. All dimensions are in millimeters.

2. Tolerance is ±0.25mm unless otherwise specified.

3. Lead spacing is measured where the leads emerge form

4. Specifications are subject to change without noticed.the package.

Specification

Absolute maximum ratings (Ta=25°C)

| Parameter | Symbol | Value | Unit |

| Power dissipation | Pd | 1700 | mW |

| Forward current | If | 500 | mA |

| Reverse voltage | Vr | 5 | V |

| Operating temperature range | Top | -40 ~+100 | °C |

| Storage temperature range | Tstg | -40~+100 | °C |

| Pulse Forward Current | Ifp | 700 | mA |

| Electrostatic Discharge | ESD | 2000(HBM) | V |

| Junction temperature | Tj | 105 | °C |

Electrical and optical characteristics(Ta=25°C)

| Parameter | Test Condition | Symbol | Value | Unit | ||

| Min | Typ | Max | ||||

| Forward voltage | If=350mA | VF | 2.8 | 3.5 | V | |

| Luminous intensity | If=350mA | Φ | 90 | 110 | Lm | |

| Viewing angle at 50% Iv | If=350mA | 2 θ 1/2 | 120 | Deg | ||

| Reverse current | Vr=5V | Ir | 10 | μA | ||

Application:

1. Lightings

2. Miner's lamp

3. Optical indicator

4. Signal & symbol luminaire.

5. Substitution of Micro incandescent lamps

6. Indoor & outdoor displays

7. Backlightings (LCD, cellular phone, switches, keys, displays, advertising)

Our advantages

1.16 years experience in manufacturing, Encapsulation Center for LED in Xiamen

2.LED components supplier for LG,TPV,Lite-on, Mitsubishi

3.Well-trained and experienced staffs to help you slove your problem

4. A experienced R&D team to help design new products

5. Strict QC system for high quality

6. Guaranteed delivery time

- Q: 0603,0805,1206,3020,3528,5050,355 what is the current and voltage of these patch LED? Please give advice!

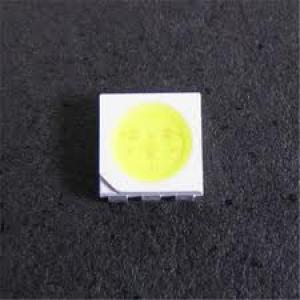

- LED patch: 0603, 0805, 1206, 1210, 5050. The 0603: conversion to metric is 1005, that of the LED element length is 1.0mm, width is 0.5mm. The trade is abbreviated as 1005, and the English name is 0603. The 0805: conversion to metric is 2125, that of the LED element length is 2.0mm, width is referred to as the 2125 inch 1.25mm. industry, it is 0805. The 1206: conversion to metric is 3216, that of the LED element length is 3.2mm, width is 1.6mm. The trade is abbreviated as 3216, and the English name is 1206. The 1210: conversion to metric is 3528, that of the LED element length is 3.5mm, width is 2.8mm. The trade is abbreviated as 3528, and the English name is 1210. The 5050: This is a metric called, said that the LED element length is 5.0mm, width is 5.0mm. Industry abbreviation 5050

- Q: What is the difference between SMT LED packaging with silicone and epoxy resin transparent package? What is the market situation of these two types of packaging?

- To package with epoxy SMD beads are used in a lot of outdoor display, because the epoxy adhesive with good adhesion to all better PPI support in outdoor use, our high quality and inexpensive epoxy epoxy call for samples

- Q: How does the LED placement lamp distinguish the positive and negative poles? There is no sign on the light. Thank you

- The light emitting diode is fixed regardless of color. The light emitting diode 1, line: foot length is positive, the negative is short. The electrodes inside the tube can also be carefully observed, while the smaller ones are positive and the large ones, similar to the bowl, are negative. 2, SMD: overlooking the side with the color line is negative, the other side is positive.

- Q: What is patch SMD-LED?

- SMD LED is the surface mount light emitting diode. It is a solid state semiconductor device that converts electricity directly into light. The heart of LED is a semiconductor wafer, one end of which is attached to a bracket, one end is negative, and the other is connected to the positive electrode of the power to encapsulate the entire wafer with epoxy resin.

- Q: What is the difference between patch LED beads and LED beads: General

- A pin of the lamp, and outside a resin cap, because the reason LED beads can spotlight cap;There is no pin on the patch and there is no resin cap outside. Because of the lack of cap, the LED patch can not be concentrated.Patch is based on small power, the shape is relatively small (usually 0.5 and 0.5W products)It's called patch because some small ones need Mounter to machine.The ordinary LED lamp, solder joints than SMD beads, now is the largest artificial welding. Regular watts count from 1-300W

- Q: Patch LED light does not flash, why?

- There are three main reasons:1, the temperature is too high, resulting in LED lights, dead lights.2, do not do anti-static measures, electrostatic breakdown chip, resulting in damage to the LED light.3, the use of LED lamp quality is too bad, the purchase price reasonable LED lights

- Q: How many volts is a single LED on the LED patch band?

- 3V or so, generally three, a group plus a resistor, power supply with 12V

- Q: What is the difference in performance between the LED plug-in and the LED patch?

- No difference, because the core of the two is the same, are diode PN junction, but no packaging, the production process is a little different

- Q: How do led patches measure good or bad?

- Use the two stage tube test of the multimeter, the red pen is connected, and the black pen is negative. If there is a bee, the sound is bad, and if the light is bright, it is good

- Q: SMD LED lamp working voltage?

- Voltage range of white LED lamp: 3.0-3.4VThe pressure drop of the red LED is 2.0--2.2VThe yellow light emitting diode has a pressure drop of 1.8 - 2.0VThe green light emitting diode has a pressure drop of 3 - 3.2VThe blue light emitting diode has a pressure drop of 3.0-3.4VSMD voltage is basically the same as double lead line. Current is generally 20~60mA, and some work current can exceed 100mA.

Send your message to us

Hot Selling 1W High Power 5050 SMD Led Diode

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 1000 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords