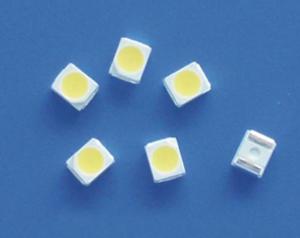

G4 SMD LED Light

- Loading Port:

- Shanghai

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 100 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Introduction

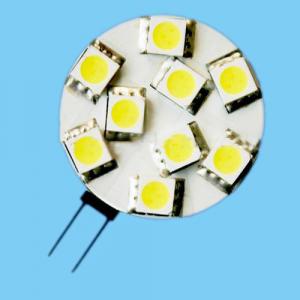

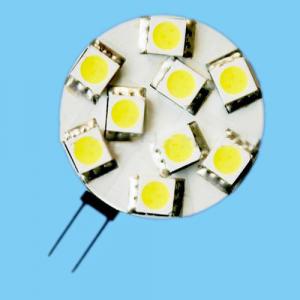

G4 SMD LED Ligh

Specification

Base: GX4.0

Power: 1.8 W

Beam angle: 120 °

Input voltage: 10-30V DC

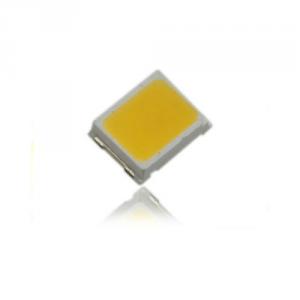

LED Qty.: 9pcs High Bright 5050 SMD

Colors: warm white, white

CRI Ra=70

Luminance: day white 6500K: 135-160 LM

warm white 3000K: 115-140 LM

Dimension: Φ28mm x L32mm × H8mm

Constant Current

Net weight: 8g

Side Pin and Back Pin

Applications

The LED Light is widely used in Super Market, Hotel, Tavern, Night Club, Disco Hall, Karaoke Room, Coffee House, Bank, Meeting Room, Exhibition Hall, Show Window, Living House and so on.

Packaging & Delivery

Package:

1 x Box

Delivery:

Shipping Service | Estimated Delivery Time |

DHL | 2-8 business days |

FedEx | 3-8 business days |

TNT | 2-10 business days |

UPS | 1-7 business days |

EMS | 6-14 business days |

ePacket | 7-12 business days |

China Post Air Mail | 7-15 business days |

China Post SAL | 14-30 business days |

By sea | 30-40 business days |

1. 3-10 business days for Sample Orders; 7-40 business days for Bulk Orders.

2. "Business days" means Monday-Friday, excluding holidays.

3. DHL and UPS cannot ship to military or P.O. boxes address.

4. The Shipping Service above is for reference only, for any other questions, please feel free to contact us.

- Q: What determines the brightness of the patch LED?

- The current through the lamp itself. If the same lamp, so it is necessary to ensure consistency in the different current circuit, the test voltage of little significance, especially in the case of parallel lamp, current a few beads each share is not the same, some big, some small.

- Q: What is the principle used in SMD LED lamp, should pay attention to what the problem?

- Pin forming, 1, LED pin molding must be completed before welding, bending angle must be more than 3mm of the gel to bend the stent. Pin over 2 times in the same place can not fold number, pin bent to 90 degrees, and then returned to the original position for 1 times; 2, pin forming must use fixture or by professional personnel to complete the first, pay attention to avoid the epoxy body caused by excessive internal wire fracture; 3, to ensure the distance between pin pin forming consistent with the circuit board; 4, when LED has good welding in the welding process or after, please don't bend light feet, to avoid damage to the lamp.

- Q: What is the difference between SMT LED packaging with silicone and epoxy resin transparent package? What is the market situation of these two types of packaging?

- To package with epoxy SMD beads are used in a lot of outdoor display, because the epoxy adhesive with good adhesion to all better PPI support in outdoor use, our high quality and inexpensive epoxy epoxy call for samples

- Q: Indoor full color LED display module and LED what is the difference between a full color?

- (1): LED full color light emitting module display module is generally yellow green, pure green module price is more expensive; SMD full color LED display using pure green tube coreThe display module (2): LED full color pixel visual feeling is thick, low brightness, easy to have the mosaic phenomenon; patch LED full color consistent, high brightness;(3): maintenance module LED full color display is not easy to maintain, the whole module replacement cost is high; SMD full-color LED screen for easy maintenance, repair and replacement of single lamp;

- Q: LED patch lamp band, how to calculate how many watts a meter, such as 3528-60 beads is how much?

- 3528 single lamp is 0.06W 0.06*60 lamp =3.6W 3528-60 bead is 3.6W/ meters

- Q: LED patches have several ways of welding. Which ones can be reflow? What can be done by eutectic welding? Is the welding of viscose and lens material is required?

- Of course, the reflow soldering is generally divided into three sections of six principle of oven temperature is 150 degrees, 190 degrees, 220 degrees, with a PC lens products can not reflow soldering, PC deformation at 150 degrees, can be heated by a soldering paste on the heating plate.

- Q: What is patch LED?

- LED is usually the lead pins form, need to be drilled on the printed circuit board, the LED pin is inserted in the hole, welded with wave soldering machine; and the patch type LED is used in welding surface, flat welded on the circuit board.

- Q: Notes on patch LED

- Storage bags are sealed and stored at a temperature of <40 DEG C.

- Q: LED package and LED SMD LED lamp, what is the difference? Will the release agent be used in that part?

- They differ in form and belong to the SMDLED category. Encapsulation uses liquid silicone and epoxy resins as well. The patches are basically made of epoxy resin. Relatively speaking, the amount of liquid silica should be relatively large.

- Q: Such as title, please have welding patch LED lamp experience expert guidance, do not search from the Internet to the theoretical knowledge, thank you!

- The welding speed and welding time because certainly give light foot heat, so the speed must be fast, tin wire and tip with better, while heating to tin iron head, avoid heating time is too long.

Send your message to us

G4 SMD LED Light

- Loading Port:

- Shanghai

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 100 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords