Hot Rolled U Channel Steel Module of SS400

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 38000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Rolled U Channel Steel Module of SS400 Details

| Standard: | AISI,ASTM,BS, DIN,GB,JIS | Dimensions: | 51*25*3-305*80*13mm | Grade: | Q235 Q345 Q460 SS400 SS540 A36 S235JR/ST37-2 ST52-3/S355JR |

| Place of Origin: | China (Mainland) | Brand Name: | CNBM | Model Number: | 51*25*3-305*80*13mm |

| Shape: | U Channel | Application: | construction, machine, vehicle, engineering | Perforated Or Not: | Not Perforated |

| galvanized: | galvanized or not galvanized |

Packaging & Delivery

| Packaging Detail: | in bundles. |

| Delivery Detail: | 25days after confirming your order |

Hot Rolled U Channel Steel Module of SS400 Specifications

Size:51*25*3-305*80*13mm

Legth:6m, 9m, 12m

Grade:Q235,SS400,ST37-2,S235JR,A36

Material: Q195 Q215 Q235 Q255 Q275 Q345 Q390 Q460 SS400 SS420 SS540 A36 S235JR/ST37- 2 ST52-3/S355JR/S355JRG3 12Mn 16Mn

Standard:

Chinese Standard : 50*37*4.5---400*102*12.5

JIS standard: 50*25*4-200*80*7.5

Standard: ASTM JIS GB DIN

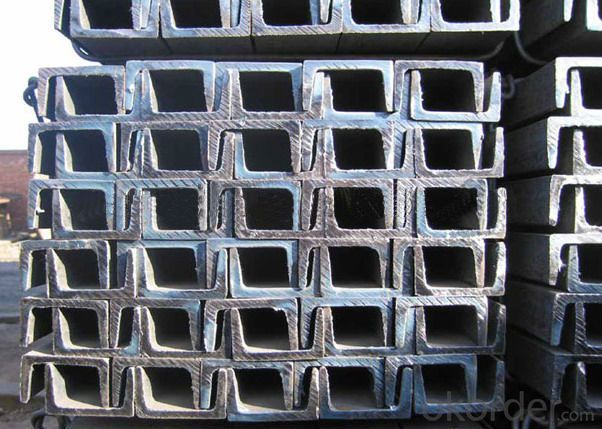

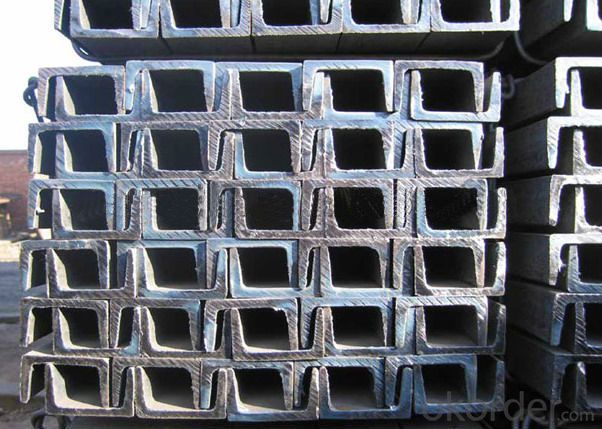

Hot Rolled U Channel Steel Module of SS400 Pictures

- Q: What are the different load distribution techniques for steel channels in floor systems?

- Some of the different load distribution techniques for steel channels in floor systems include continuous distribution, point distribution, and moment distribution. Continuous distribution involves evenly distributing the load along the length of the channel, while point distribution concentrates the load at specific points along the channel. Moment distribution accounts for the bending moments and distributes the load accordingly. These techniques help ensure efficient load distribution and structural integrity in steel channel floor systems.

- Q: Can steel channels be used in the telecommunications manufacturing industry?

- Certainly, the telecommunications manufacturing industry can make use of steel channels. These channels are widely employed across various sectors, including telecommunications, owing to their exceptional strength, durability, and adaptability. Within the telecommunications field, steel channels serve numerous purposes, such as housing cable trays, providing support for antennas and satellite dishes, constructing equipment racks, and enclosing vital components. By utilizing steel channels, telecommunications equipment and infrastructure can be securely and effectively supported and shielded. Moreover, steel channels can be readily manufactured and tailored to meet specific demands, rendering them highly suitable for the diverse requirements of the telecommunications manufacturing industry.

- Q: Are steel channels suitable for use in industrial settings?

- Yes, steel channels are highly suitable for use in industrial settings. Steel channels are versatile and robust structural components that provide excellent strength and stability, making them an ideal choice for various applications in industrial environments. One of the key advantages of steel channels is their high load-bearing capacity. Industrial settings often involve heavy machinery, equipment, and materials, which require strong and durable support structures. Steel channels can withstand significant loads and provide a reliable framework for various industrial operations. Moreover, steel channels are known for their resistance to corrosion and weathering. Industrial settings frequently expose materials to harsh conditions, such as moisture, chemicals, and extreme temperatures. Steel channels, especially those made from corrosion-resistant alloys, can withstand these environmental challenges and maintain their structural integrity over time. Another important factor that makes steel channels suitable for industrial settings is their versatility. Steel channels come in various shapes, sizes, and thicknesses, allowing them to be adapted to different requirements and applications. They can be easily fabricated, cut, and welded to create customized structures that meet specific industrial needs. Furthermore, steel channels offer excellent fire resistance, which is crucial in industrial environments where fire hazards are a concern. Steel has a high melting point and does not contribute to the spread of flames, making it a safe choice for industrial structures. In addition to their technical advantages, steel channels are also cost-effective in the long run. Steel is a durable material that requires minimal maintenance, reducing the need for frequent repairs or replacements. Moreover, steel is widely available and can be recycled, making it an environmentally friendly choice. In conclusion, steel channels are highly suitable for use in industrial settings due to their strength, durability, resistance to corrosion and fire, versatility, and cost-effectiveness. Whether it's for supporting heavy loads, creating customized structures, or withstanding harsh environments, steel channels offer reliable and efficient solutions for various industrial applications.

- Q: Can steel channels be used for supporting signage and billboards?

- Yes, steel channels can be used for supporting signage and billboards. Steel channels are known for their strength and durability, making them suitable for providing structural support to hold and secure various types of signage and billboards.

- Q: What are the different types of clamps used for steel channels?

- Steel channels require different types of clamps to serve their specific purposes. These clamps ensure stability and structural integrity in various applications. 1. Beam clamps: These clamps attach steel channels to beams or other structural members. They have a screw or bolt mechanism for easy installation and adjustment, providing a secure attachment point. 2. U-bolt clamps: U-bolt clamps are U-shaped and used to secure steel channels to pipes, rods, or other cylindrical objects. They offer a strong and reliable connection, commonly used for round or curved surfaces. 3. Pipe clamps: Pipe clamps support steel channels attached to pipes. They have a split design for easy installation around the pipe, secured with screws or bolts. 4. Rigid clamps: Rigid clamps are heavy-duty and provide maximum strength and stability. They create a rigid connection between steel channels and other structural components, preventing movement or flexing. 5. Channel clamps: Channel clamps connect two steel channels. They often have a sliding mechanism for easy adjustment and alignment, ensuring a secure and precise connection. Apart from these clamps, there may be variations or specialized options available for specific requirements. It is crucial to select the appropriate clamp based on the specific needs of the steel channel installation to ensure proper support and durability.

- Q: What are the guidelines for steel channel installations in corrosive environments?

- To ensure the steel channels installed in corrosive environments remain durable and long-lasting, it is crucial to adhere to specific guidelines. Consider the following recommendations: 1. Material Selection: Opt for steel channel materials specifically designed for corrosive environments, such as stainless steel or galvanized steel. These materials are known for their corrosion resistance. 2. Protective Coatings: Apply suitable protective coatings to the steel channels to prevent corrosion. Options include anti-corrosion paints, epoxy coatings, or zinc-rich coatings. The coating should act as a barrier between the steel and the corrosive environment. 3. Adequate Ventilation: Proper airflow and ventilation are essential in corrosive environments to minimize the accumulation of corrosive gases or chemicals. Ensure the installation allows for sufficient ventilation to prevent the buildup of corrosive elements. 4. Regular Maintenance: Regularly inspect and maintain the steel channel installation to detect any signs of corrosion or damage. Promptly address any issues by cleaning, repairing, or replacing affected sections to prevent further corrosion. 5. Avoid Contact with Dissimilar Metals: Prevent direct contact between the steel channel and dissimilar metals to avoid galvanic corrosion. If different metals must be in close proximity, use insulating materials or appropriate coatings to separate them. 6. Drainage: Design the installation to facilitate effective drainage of any liquid or moisture that may come into contact with the steel channel. Standing water or moisture can accelerate corrosion, so ensure proper drainage. 7. Professional Consultation: Seek advice from professionals or corrosion engineers experienced in dealing with corrosive environments. They can provide specific guidance based on the unique conditions of the environment and recommend suitable measures to protect the steel channel. By adhering to these guidelines, the risk of corrosion in steel channel installations in corrosive environments can be minimized, ensuring their long-term performance and structural integrity.

- Q: Are steel channels available in different lengths?

- Different lengths of steel channels are readily available. These channels, which can also be referred to as C-channels or U-channels, are made of steel and have either a C or U shape. They are commonly utilized in construction, manufacturing, and various other industries. Manufacturers typically produce steel channels in standard lengths, although these lengths may vary depending on the specific requirements of the project and the manufacturer itself. Some standard lengths for steel channels include 10 feet, 20 feet, and 40 feet. However, custom lengths can also be manufactured to meet the unique needs of a project. The availability of different lengths provides flexibility and versatility in construction and design. Whether it is for constructing frames, supports, or other structural elements, steel channels can be cut or joined together to achieve the desired length. This adaptability makes steel channels a favored choice in various applications, as they can be easily tailored to fit specific project requirements. To sum up, steel channels are indeed available in different lengths, including both standard sizes and custom lengths. Their availability in various lengths allows for their widespread use in a wide range of construction and industrial projects.

- Q: How do steel channels contribute to daylighting in buildings?

- Steel channels can contribute to daylighting in buildings by being used as structural components for large windows or skylights. These channels provide the necessary support and framing for these daylighting features, allowing more natural light to enter the building and reducing the need for artificial lighting.

- Q: Can steel channels be used for stair stringers in commercial buildings?

- Yes, steel channels can be used as stair stringers in commercial buildings. Steel channels are often preferred for their strength, durability, and load-bearing capabilities, making them suitable for supporting staircases in high-traffic areas such as commercial buildings. Additionally, steel channels can be easily fabricated and installed, providing a reliable and long-lasting solution for stair stringers in these settings.

- Q: How do steel channels contribute to the stability of a structure during tornadoes?

- Steel channels contribute to the stability of a structure during tornadoes in several ways. Firstly, steel channels are made of high-strength steel, which provides excellent resistance to both compression and tension forces. This strength allows the channels to withstand the powerful winds and forces that tornadoes generate. Moreover, steel channels are often used as structural members in the framing of a building. They are typically installed vertically or horizontally between the main columns and beams, creating a network of interconnected support. This framework helps distribute the load and forces generated by the tornado throughout the structure, preventing concentrated stress points and potential collapses. Additionally, steel channels can be strategically placed in load-bearing walls or as bracing elements to enhance the structural integrity of a building. These channels act as reinforcements, providing extra support and stiffness to the walls, which is crucial during tornadoes when the structure is subjected to intense wind pressures. This reinforcement helps to prevent the walls from buckling or collapsing under the extreme forces. Furthermore, steel channels are often utilized in the construction of storm shelters or safe rooms, which are specifically designed to protect occupants during tornadoes. These channels are incorporated into the walls, ceiling, and floor of these shelters, providing a robust and secure enclosure that can withstand the destructive forces of a tornado. Overall, steel channels play a crucial role in enhancing the stability of a structure during tornadoes. Their high strength, ability to distribute forces, and reinforcement capabilities make them an essential component in ensuring the safety and integrity of buildings in tornado-prone areas.

Send your message to us

Hot Rolled U Channel Steel Module of SS400

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 38000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords