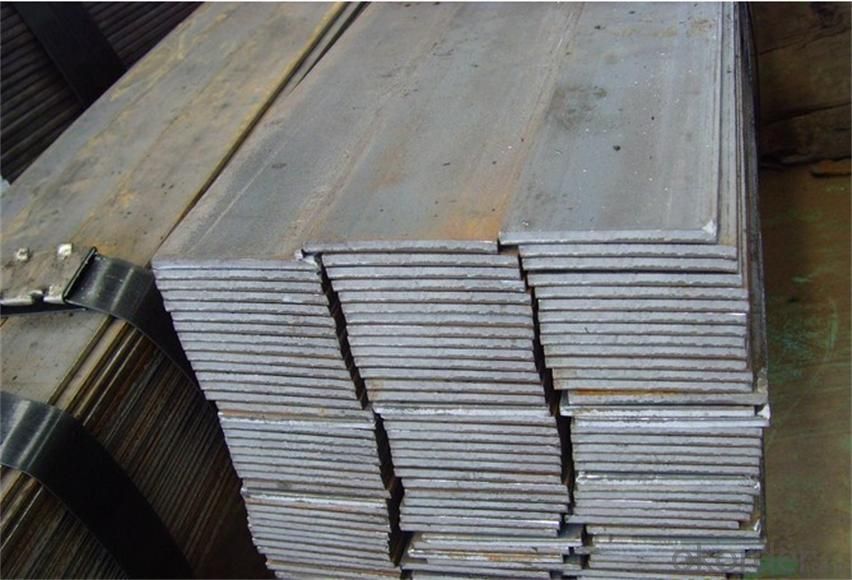

Hot rolled steel flat bar in Grade Q235 for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering hot rolled steel flat bar in Grade Q235 for construction at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot rolled steel flat bar are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel Flat Bar for construction are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Chinese Standard (H*W*T) | Weight (Kg/m) | 6m (pcs/ton) | Light I (H*W*T) | Weight (Kg/m) | 6m (pcs/ton) | Light II (H*W*T) | Weight (Kg/m) | 6M |

100*68*4.5 | 11.261 | 14.8 | 100*66*4.3 | 10.13 | 16.4 | 100*64*4 | 8.45 | 19.7 |

120*74*5.0 | 13.987 | 11.9 | 120*72*4.8 | 12.59 | 13.2 | 120*70*4.5 | 10.49 | 15.8 |

140*80*5.5 | 16.89 | 9.8 | 140*78*5.3 | 15.2 | 10.9 | 140*76*5 | 12.67 | 13.1 |

160*88*6 | 20.513 | 8.1 | 160*86*5.8 | 18.46 | 9 | 160*84*5.5 | 15.38 | 10.8 |

180*94*6.5 | 24.143 | 6.9 | 180*92*6.3 | 21.73 | 7.6 | 180*90*6 | 18.11 | 9.2 |

200*100*7 | 27.929 | 5.9 | 200*98*6.8 | 25.14 | 6.6 | 200*96*6.5 | 20.95 | 7.9 |

220*110*7.5 | 33.07 | 5 | 220*108*7.3 | 29.76 | 5.6 | 220*106*7 | 24.8 | 6.7 |

250*116*8 | 38.105 | 4.3 | 250*114*7.8 | 34.29 | 4.8 | 250*112*7.5 | 28.58 | 5.8 |

280*122*8.5 | 43.492 | 3.8 | 280*120*8.2 | 39.14 | 4.2 | 280*120*8 | 36.97 | 4.5 |

300*126*9 | 48.084 | 3.4 | 300*124*9.2 | 43.28 | 3.8 | 300*124*8.5 | 40.87 | 4 |

320*130*9.5 | 52.717 | 3.1 | 320*127*9.2 | 48.5 | 3.4 | |||

360*136*10 | 60.037 | 2.7 | 360*132*9.5 | 55.23 | 3 |

FAQ

Q1: What makes stainless steel stainless?

A1: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q2: Can stainless steel rust?

A2: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

- Q: Can steel flat bars be used in the manufacturing of material handling equipment?

- Yes, steel flat bars can be commonly used in the manufacturing of material handling equipment. They provide strength, durability, and stability, making them suitable for various applications such as conveyor systems, lifting equipment, and storage racks. Additionally, steel flat bars can be easily welded, bent, and formed into desired shapes, allowing flexibility in design and customization for specific equipment requirements.

- Q: What are the different types of finishes available for steel flat bars?

- Steel flat bars offer a variety of finishes, each with their own advantages and aesthetic appeal. Here are some of the most common finishes: 1. Mill Finish: The standard finish for steel flat bars is achieved through hot rolling, resulting in a plain and smooth surface. This creates an industrial and clean look. 2. Hot Rolled Pickled and Oiled (HRPO): This finish involves an additional process where the steel flat bar is pickled in an acid bath to remove impurities, and then oiled to prevent rust. HRPO finish offers improved corrosion resistance and a slightly smoother surface. 3. Cold Rolled: For a smoother and more precise surface, the steel flat bar is passed through rollers at room temperature. Cold rolled finish is popular for applications requiring a high-quality appearance. 4. Galvanized: To protect against corrosion, the steel flat bar is coated with a layer of zinc. This galvanized finish is highly durable and suitable for outdoor use. 5. Powder Coated: A dry powder is applied to the steel flat bar and baked to create a strong and protective finish. Powder coating comes in various colors and offers excellent resistance to chipping, peeling, and fading. 6. Brushed: Achieved by rubbing the surface with a wire brush or abrasive material, a brushed finish creates a textured and satin-like appearance. It is often used for decorative purposes and helps conceal scratches or imperfections. 7. Polished: This finish involves grinding the surface to a smooth and reflective appearance. Polishing is commonly used in architectural or decorative applications for a high-end, mirror-like look. These examples highlight the range of finishes available for steel flat bars. The choice of finish depends on factors such as the intended use, desired appearance, and environmental conditions affecting corrosion resistance.

- Q: Are steel flat bars suitable for structural applications?

- Certainly, steel flat bars are appropriate for structural purposes. They find extensive use in the construction field for beams, columns, and braces. Steel flat bars possess numerous advantages that render them well-suited for structural applications. First and foremost, steel is renowned for its robustness and durability, and this characteristic extends to flat bars as well. They exhibit a high tensile strength, enabling them to withstand substantial loads and provide structural stability. Furthermore, steel flat bars exhibit exceptional resistance to bending and twisting forces, instilling confidence in their reliability for structural endeavors. Moreover, steel flat bars are adaptable and conveniently modifiable to satisfy specific design requirements. They can be effortlessly cut, welded, drilled, and shaped to create diverse structural elements, thereby affording flexibility in construction projects. Additionally, steel flat bars are available in various sizes and thicknesses, facilitating customization to accommodate precise structural needs. Furthermore, steel proves to be a cost-effective material for structural applications. It is readily accessible and boasts a lengthy lifespan, thereby diminishing the necessity for frequent maintenance or replacements. Steel also possesses commendable fire resistance properties, a vital characteristic in ensuring structural safety. To conclude, steel flat bars are undeniably appropriate for structural applications, owing to their strength, durability, versatility, and cost-effectiveness. They enjoy widespread utilization within the construction industry and offer a multitude of benefits that solidify their status as a dependable choice for various structural components.

- Q: How do steel flat bars contribute to the energy efficiency of buildings?

- Steel flat bars can contribute to the energy efficiency of buildings in several ways. Firstly, steel is a highly durable material that can withstand extreme weather conditions, such as high winds and heavy rain, which can help in maintaining the structural integrity of the building over time. This durability leads to a longer lifespan for the building, reducing the need for frequent repairs or replacements, resulting in energy and cost savings. Additionally, steel flat bars are often used in the construction of windows and doors. These components play a crucial role in the energy efficiency of a building as they help to minimize heat transfer and air leakage. Steel, being a poor conductor of heat, can provide excellent insulation properties when used in window frames or door frames. This insulation helps to prevent heat loss during cold winter months and heat gain during hot summer months, reducing the reliance on heating or cooling systems and improving energy efficiency. Furthermore, steel flat bars can be used as structural elements in the building's envelope, such as in wall framing or roof trusses. The use of steel in these applications allows for the construction of lighter and stronger structures, which can facilitate the use of larger windows or open floor plans. This, in turn, promotes natural daylighting and ventilation, reducing the need for artificial lighting and mechanical ventilation systems. By maximizing the use of natural resources, steel flat bars contribute to the overall energy efficiency of the building. Lastly, steel is a recyclable material, meaning that after its use in a building, it can be easily recycled and repurposed for other applications. This promotes sustainable construction practices and reduces the overall environmental impact of the building industry. By choosing steel flat bars for construction, builders contribute to a circular economy, where materials are reused rather than disposed of, further enhancing the energy efficiency and sustainability of the building. In conclusion, steel flat bars contribute to the energy efficiency of buildings through their durability, insulation properties, structural benefits, and recyclability. By utilizing steel in various building components, builders can create more sustainable and energy-efficient structures, leading to long-term cost savings and reduced environmental impact.

- Q: Can steel flat bars be used as structural support in buildings?

- Steel flat bars can indeed serve as structural support in buildings. They are widely employed in construction owing to their impressive strength and longevity. Their versatility allows them to be utilized in beams, columns, and braces, among other applications. With their exceptional load-bearing capacity, steel flat bars can withstand substantial burdens, making them ideal for building structures. Furthermore, their consistent shape and size facilitate easy integration into construction projects. All in all, steel flat bars are a dependable option for delivering structural support in buildings.

- Q: What are the different storage and handling requirements for steel flat bars?

- The storage and handling requirements for steel flat bars can vary depending on the specific type of steel and environmental conditions. However, there are some common guidelines that can be followed to ensure the proper storage and handling of steel flat bars. 1. Storage: Steel flat bars should be stored in a dry, well-ventilated area to prevent moisture and humidity from causing corrosion. They should be kept away from direct contact with the ground to avoid any potential damage. Stacking the bars on racks or pallets is recommended to maintain their shape and prevent deformation. 2. Handling: Steel flat bars should be handled with care to prevent any bending, twisting, or scratching. Employees should use appropriate lifting equipment, such as forklifts or cranes, to move and transport the bars. It is important to secure the bars properly during transportation to avoid any accidents or damage. 3. Protection: Steel flat bars should be protected from exposure to moisture, chemicals, and extreme temperatures. They should be covered with a suitable protective coating, such as oil or paint, to prevent rust and corrosion. Additionally, the bars should be stored away from any materials that could potentially cause damage, such as acids or alkaline substances. 4. Inspection: Regular inspection of steel flat bars is essential to identify any signs of corrosion, deformation, or other defects. Any damaged or compromised bars should be removed from storage and either repaired or replaced, depending on their condition. 5. Documentation: It is important to maintain proper documentation of the storage and handling of steel flat bars. This includes recording the date of receipt, the quantity, and any relevant details such as the supplier or manufacturer. This documentation can be useful for quality control purposes and in case of any disputes or warranty claims. By following these storage and handling requirements, steel flat bars can be preserved in good condition, ensuring their durability and usability for various applications.

- Q: What is the surface area of flat steel 100*3 meters per metre?

- 2X (0.1x1+0.003x1+0.1x0.003) =0.2066 with a surface area of 0.2066 square meters.Flat, refers to the width 12-300mm, thickness 4-60mm, cross section is rectangular in shape and with a blunt edge of steel.

- Q: What are the typical tolerances for steel flat bars?

- The tolerances for steel flat bars can vary depending on the specific industry and application. Typically, the standard tolerances for steel flat bars are +/- 1/8 inch. This means that the steel flat bars can deviate by up to 1/8 inch from the specified dimensions. It is important to consider that these tolerances can be influenced by factors such as the manufacturing process, the grade of steel used, and any additional specifications or requirements from the customer or industry standards. For precise applications or industries that require high accuracy and consistency, tighter tolerances may be necessary. In such cases, the tolerances for steel flat bars can be specified more precisely, such as +/- 0.005 inches or even tighter. Ultimately, the specific tolerances for steel flat bars will depend on the project requirements, industry standards, and the capabilities of the manufacturer. It is recommended to consult relevant standards or work with a trusted supplier to ensure that the tolerances meet the desired specifications for a particular application.

- Q: Are steel flat bars commonly used in the construction of educational institutions?

- Yes, steel flat bars are commonly used in the construction of educational institutions. Steel flat bars offer several advantages that make them a popular choice in construction projects. Firstly, steel is a strong and durable material, which ensures the structural integrity and longevity of buildings. This is especially important in educational institutions where safety is a top priority. Secondly, steel flat bars can be easily fabricated and customized to meet specific design requirements. They can be cut, bent, and welded to create various shapes and sizes, making them versatile for different construction applications. Steel flat bars are often used as support beams, lintels, and framing components in educational buildings. Additionally, steel is a sustainable material that can be recycled, making it an environmentally friendly choice for construction projects. This aligns with the increasing focus on sustainability and green building practices in educational institutions. Furthermore, steel flat bars have excellent fire-resistant properties, providing an added layer of safety. In the event of a fire, steel does not contribute to the spread of flames, which is crucial in educational buildings where large numbers of people gather. Overall, the combination of strength, versatility, sustainability, and fire resistance make steel flat bars a commonly used material in the construction of educational institutions.

- Q: Can steel flat bars be easily machined?

- Yes, steel flat bars can be easily machined. Steel is a widely used material in various industries due to its excellent machinability properties. It can be easily shaped, cut, and formed into different configurations, including flat bars. Machining processes such as milling, drilling, turning, and grinding can be performed on steel flat bars with relative ease. However, the specific machinability of steel can vary depending on its composition, hardness, and other factors. It is important to consider the specific type of steel and its properties to ensure proper machining techniques and tools are used for optimal results.

Send your message to us

Hot rolled steel flat bar in Grade Q235 for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords