Hot Rolled Seamless Steel Pipe With Great Price Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 35 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Hot Rolled Seamless Steel Pipe With Great Price Made in China

1.Structure of Seamless Steel Pipe :

Seamless pipe is formed by drawing a solid billet over a piercing rod to create the hollow shell. Historically seamless pipe was regarded as withstanding pressure better than other types, and was often more easily available than welded pipe. As the manufacturing process does not include any welding, seamless pipes are perceived to be stronger and more reliable.

2.Main Features of the Seamless Steel Pipe :

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

• High manufacturing accuracy

• High strength

• Small inertia resistance

3.Seamless Steel Pipe Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

4. Application of Seamless Steel Pipe :

Seamless stainless pipe is used for applications that require internal pressure within the pipe such as process equipment, water treatment and marine applications. Welded pipe is used for structural applications that are exposed to corrosive environments such as marine and external applications. These include handrails, poles and support piping.

5.FAQ of Seamless Steel Pipe :

A.How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

B.How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

C. Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

Any question, pls feel free to contact us !

6. Company Information:

Since 2004, the trading volume of CNBM International has been doubled in 5 successive years owing to the support of superior corporations and effort of all staff. Meanwhile, we have established strategic partnerships with hundreds of domestic manufacturers and sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target.In line with the business, CNBM International launched E-business platform Okorder.com.Our goal is to transform CNBM International into the global leading brand in building materials industry within 3 to 5 years through innovation and reform, by strengthening the overall management of supply chain, developing and cultivating both domestic and overseas market, improving the procedure and information system, enhancing the ability to organize resources and to provide value-added services under a professional team and a learning organization.

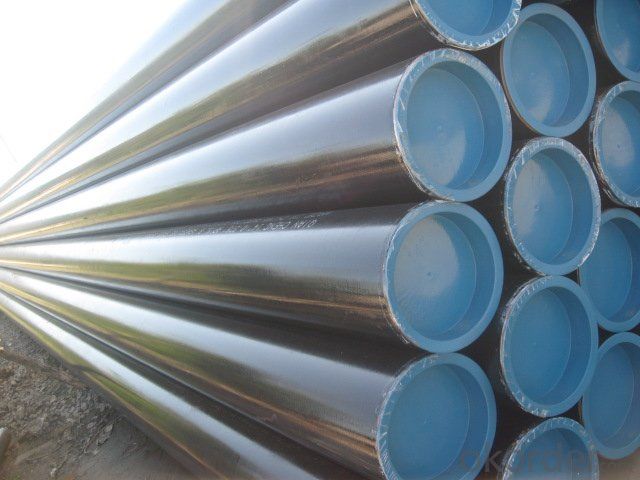

7.Seamless Steel Pipe Images:

- Q: What are the common uses of stainless steel pipes?

- Stainless steel pipes are widely used in various industries for a multitude of applications. Some of the common uses of stainless steel pipes include: 1. Plumbing and Water Supply: Stainless steel pipes are often used in residential, commercial, and industrial plumbing systems due to their corrosion resistance, durability, and ability to handle high-pressure applications. They are also used in water treatment plants and wastewater management systems. 2. Oil and Gas Industry: Stainless steel pipes are extensively used in the oil and gas industry for transporting oil, gas, and other fluids. They can withstand high temperatures, pressure, and corrosive environments, making them ideal for this industry. 3. Food and Beverage Industry: Stainless steel pipes are widely used in the food and beverage industry due to their hygienic properties and resistance to corrosion. They are commonly used for transporting liquids, gases, and food products in processing plants, breweries, wineries, dairies, and other food-related facilities. 4. Chemical and Petrochemical Industry: Stainless steel pipes are critical in the chemical and petrochemical industry, where they are used for transporting corrosive chemicals, acids, and other hazardous substances. The pipes' resistance to corrosion and high temperatures makes them suitable for these demanding applications. 5. Construction and Architecture: Stainless steel pipes are used in construction and architecture for various purposes such as structural support, handrails, guardrails, and decorative elements. Their strength, durability, and aesthetic appeal make them a popular choice in modern architectural designs. 6. Automotive and Transportation: Stainless steel pipes are used in the automotive industry for exhaust systems, fuel lines, and other components that require resistance to high temperatures and corrosion. They are also used in the transportation of fluids and gases in ships, trains, and airplanes. 7. Pharmaceutical Industry: The pharmaceutical industry requires high-quality materials that meet stringent sanitary standards. Stainless steel pipes are commonly used in pharmaceutical manufacturing processes for transporting liquids, gases, and chemicals due to their cleanability, corrosion resistance, and compatibility with pharmaceutical products. 8. Power Generation: Stainless steel pipes are used in power plants, both conventional and renewable, for various applications such as steam lines, condensers, and heat exchangers. They are chosen for their ability to withstand high temperatures, pressure, and corrosive environments. In summary, stainless steel pipes find applications in a wide range of industries including plumbing, oil and gas, food and beverage, chemical and petrochemical, construction, automotive, pharmaceutical, and power generation. Their corrosion resistance, durability, and ability to handle high temperatures and pressure make them a versatile and reliable choice for various industrial applications.

- Q: How are steel pipes used in the manufacturing sector?

- Steel pipes are used in the manufacturing sector for various purposes such as transporting fluids and gases, supplying water, and carrying out structural applications. They are commonly used in industries like oil and gas, construction, automotive, and aerospace for their durability, strength, and resistance to corrosion. Additionally, steel pipes are crucial in the manufacturing of machinery, equipment, and infrastructure, making them essential components in many manufacturing processes.

- Q: What are the different types of steel pipe coatings for nuclear power plants?

- There are several types of steel pipe coatings used in nuclear power plants, including epoxy coatings, polyethylene coatings, fusion bonded epoxy coatings, and coal tar enamel coatings. These coatings are applied to steel pipes to provide protection against corrosion, enhance durability, and maintain the integrity of the pipes in the demanding environment of nuclear power plants.

- Q: How are steel pipes used in petrochemical plants?

- Steel pipes are extensively used in petrochemical plants for various purposes such as transporting fluids and gases, as well as providing structural support. These pipes are commonly utilized for the safe and efficient transfer of crude oil, natural gas, and other chemicals within the plant. They are designed to withstand high pressure, extreme temperature conditions, and corrosive environments, ensuring the integrity and reliability of the plant's operations. Steel pipes also play a crucial role in the construction of process equipment, such as reactors, distillation columns, and heat exchangers, providing a durable and long-lasting solution for the petrochemical industry.

- Q: How are steel pipes used in the pulp and paper industry?

- Steel pipes are widely used in the pulp and paper industry for various applications. They are primarily used for conveying corrosive chemicals, hot water, steam, and other fluids throughout the production process. Steel pipes provide high strength, durability, and resistance to corrosion, which is crucial in an industry where harsh chemicals are involved. They are used in the transportation of pulp, bleaching agents, and various liquids within the production facilities, ensuring efficient and reliable operations in the pulp and paper industry.

- Q: How are steel pipes used in the manufacturing of appliances?

- Steel pipes are commonly used in the manufacturing of appliances as they are strong, durable, and resistant to corrosion. These pipes are used for various purposes such as supply and distribution of water, gas, and other fluids, as well as for structural support and framework in appliances. They are often used for creating the internal plumbing systems, ventilation ducts, and electrical conduits in appliances, ensuring efficient functioning and reliability.

- Q: What's the gate number of the precision steel pipe?

- This kind of steel tube and ordinary hot-rolled seamless steel pipe and cold drawn seamless steel tube in the outer surface is different from the outer surface, and the diameter of the smooth finish of precision steel tube, stainless steel color and the same, inside and outside surface due to manufacturing reasons with a layer of oil.

- Q: Can steel pipes be used for conveying gases?

- Indeed, gases can be conveyed using steel pipes. In different industries, such as oil and gas, petrochemical, and construction, steel pipes are commonly employed to transport a wide range of gases, including natural gas, air, and hydrogen. The use of steel pipes for gas transportation offers numerous benefits. They possess exceptional strength and durability, enabling them to withstand rigorous pressure and temperature conditions. Moreover, steel pipes exhibit remarkable resistance to corrosion, effectively preventing gas leakage and ensuring the safety and dependability of the gas transportation system. Furthermore, their smooth internal surface minimizes frictional resistance, facilitating efficient gas flow. As a result, steel pipes are a reliable and extensively-utilized choice for conveying gases across diverse applications.

- Q: What's the use of steel pipe?

- No other type of steel can replace the steel tube entirely, but the steel tube can take the place of some sections and bars. Steel pipe is very important to the development of national economy and the improvement of human life quality, much better than other steel products. From the people's daily utensils, furniture, water supply and drainage, gas supply, ventilation and heating facilities to all kinds of agricultural machinery equipment manufacturing, underground resources development, national defense and space use guns, bullets, missiles, rockets and so cannot do without steel.

- Q: What is the fire rating of steel pipes?

- Several factors determine the fire rating of steel pipes. Steel possesses inherent fire resistance due to its high melting point and low thermal conductivity. However, the fire rating of steel pipes can be further improved by employing fire-resistant coatings or insulation materials. These additional measures can offer different levels of fire protection, typically quantified by how long the pipes can retain their structural integrity during a fire situation. The precise fire rating of steel pipes may differ depending on the thickness and type of coating or insulation employed. To ascertain the appropriate fire rating requirements for specific applications, it is crucial to refer to industry standards, such as those established by organizations like the National Fire Protection Association (NFPA), or consult with fire safety professionals.

Send your message to us

Hot Rolled Seamless Steel Pipe With Great Price Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 35 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords