Hot Rolled JIS U-channel Carbon Steel HIgh Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering STEEL CHANNEL at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

1.The JIS channel can be devided into two kinds, namely common channel steel and light channel steel. The sizes of hot rolled common channel steel range from 5# to 40#. Meanwhile, the channel steel can be divided into cold forming sectional equal channel steel, cold forming sectional unequal channel steel, cold forming inner edge channel steel and outer edge channel steel.

2.The JIS channel is usually used for arch-itechtural structure, and they could be welded in order to support or hang a vari-ety of facilities. They are also usually used in combination with I beam. The channel steel with sizes under 14# is usually applied to construction engineering, as purline, while the channel steel with sizes above 16# is more likely to be used in building vehicle chassis structure and mechanical structure. Furthermore, the channel steel in sizes above 30# are target at building bridge structure, as tension bar.

3.In a word, the channel steel must possess perfect welding property, riveting property and mechanical property and so on.

Product Advantages:

OKorder's STEEL CHANNELare durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Minimum Order Quantity: 25 Tons Unit: m.t. Loading Port: Xingang Port

Supply Ability: 1000 Tons Per Day Payment Terms: TT or L/C

Product Description:

Specifications of Steel U Channel:

Standard Applied: GB Standard, EN Standard(UPN), JIS Standard

Sizes: 50mm to 300mm

Material Grade: Q235B, Q345B, S235JR, SS400, ASTM A36

Alloy No | Grade | Element(%) | ||||

C | Mn | S | P | Si | ||

Q235 | B | 0.12-0.20 | 0.3-0.7 | ≦0.045 | ≦0.045 | ≦0.3 |

Alloy No | Grade | Yielding Strength Point(Mpa) | |||

Thickness(mm) | |||||

≦16 | >16-40 | >40-60 | >60-100 | ||

≧ | |||||

Q235 | B | 235 | 225 | 215 | 205 |

Table-3-1

Alloy No | Grade | Tensile Strength(Mpa) | Elongation After Fracture(%) | |||

Thickness(mm) | ||||||

≦16 | >16-40 | >40-60 | >60-100 | |||

≧ | ||||||

G235 | B | 375-500 | 26 | 25 | 24 | 23 |

Production Flow of JIS Channel:

1.The steel billet shall be heated in the high temperature furnace.

2. The heated steel billet shall be rolled five to nine times with the aim of shaping the general figure of steel u channel.

3. The rolled steel channel should be put onto the cooling bed to make the temperature low.

4. The JIS Channel should be straighted on the straightener.

5. The straighted steel u channel will be cut into meters by saw, as per customer's requirements.

6. At the last part of production, the channel steel must be tested in order to confirm that the finished products are completely free from crack, pore, slag, scab or fold on the surface.

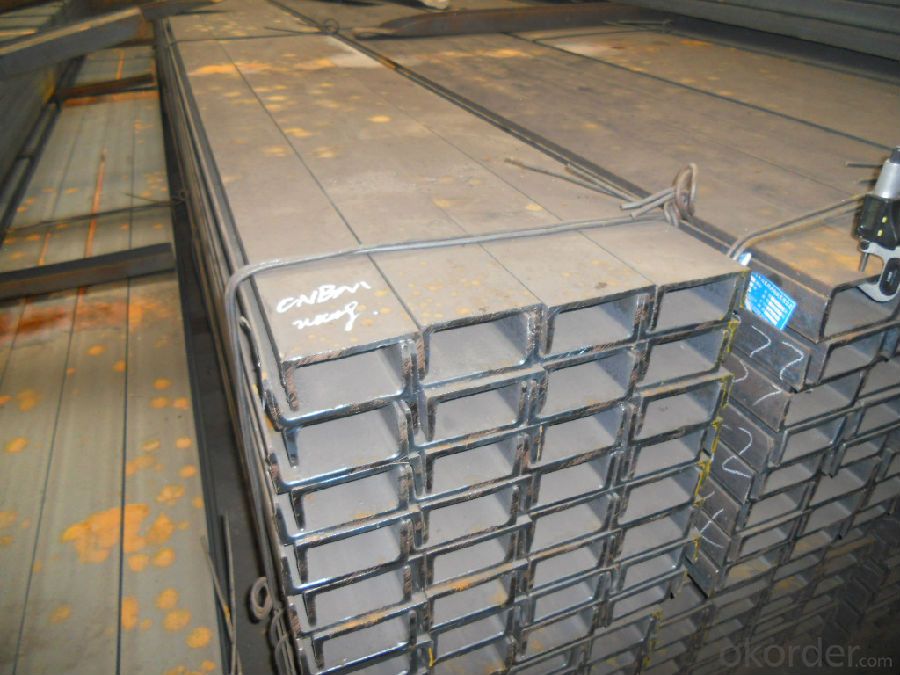

Package & Delivery: Steel U Channel

The steel u channel will be packed in bundle with steel wire at each end of every bundle and color marking in order to help the customer to recognize his goods more easily at sight.

And steel u channel could be loaded into 20ft or 40ft container, or by bulk cargo. If the weight of each bundle reaches less than 3.5 mt, the loading by break bulk cargo should be choosed. When the weight of each bundle reaches less than 3mt, the loading by container should be choosed.

As for the transportaion from mill to loading port, the truck will be usually used. And the maximum quantity for each truck is 40mt.

All in all, we could do in accordance with customer's request

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Images:

- Q: What are the common material testing procedures for steel channels?

- Steel channels undergo a range of tests to assess their quality and properties. These tests include: 1. Tensile Test: This test determines the tensile strength, yield strength, and elongation of the steel channels. The sample is gradually loaded until it breaks, and the stress-strain relationship is measured. 2. Hardness Test: The hardness of the steel channels is measured using methods like Rockwell, Brinell, or Vickers tests. It indicates the material's resistance to indentation or scratching. 3. Charpy Impact Test: This test evaluates the toughness and impact resistance of the steel channels. A notched sample undergoes a high-velocity impact, and the absorbed energy is measured. This helps assess the material's ability to withstand sudden shocks. 4. Bend Test: This test assesses the ductility and deformation behavior of the steel channels. A sample is bent to a specific angle without breaking, and the extent of bending is examined to ensure it meets required standards. 5. Chemical Analysis: Steel channels undergo chemical analysis to determine their composition, including the percentage of carbon, manganese, silicon, sulfur, phosphorus, and other alloying elements. This ensures the material meets specific requirements. 6. Ultrasonic Testing: Ultrasonic waves are used to detect any internal flaws or defects in the steel channels. This non-destructive method helps identify cracks, voids, or inclusions that may compromise the material's quality. 7. Dimensional Inspection: The dimensions and tolerances of the steel channels are measured to ensure they meet required specifications. This includes checking the width, height, thickness, and overall geometry of the channels. These testing procedures are vital in ensuring the quality, strength, and performance of steel channels, making them suitable for various industries such as construction, manufacturing, and infrastructure.

- Q: How do steel channels contribute to the overall structural integrity of a building?

- Steel channels contribute to the overall structural integrity of a building by providing strength, support, and stability. These channels are often used as beams or columns in construction, allowing them to bear heavy loads and distribute weight evenly throughout the structure. The robustness of steel channels helps to resist bending, buckling, and other forms of deformation, ensuring that the building can withstand various external forces such as wind, seismic activity, and the weight of the structure itself. Additionally, steel channels are highly durable and fire-resistant, further enhancing the safety and longevity of the building.

- Q: What does "14 channel steel" do in the template "[14"?

- Specification for dimensions and weight of hot rolled ordinary channel steel14#a height (H) 140, leg width (b) 58, waist thickness (d) 6, theoretical weight 14.535 kg14#b height (H) 140, leg width (b) 60, waist thickness (d) 8, theoretical weight 16.733 kg

- Q: What are the safety considerations for working with steel channels?

- When working with steel channels, there are several safety considerations that should be taken into account to ensure the well-being of individuals involved in the process. 1. Personal Protective Equipment (PPE): It is essential to wear appropriate PPE, including safety glasses, steel-toed boots, gloves, and a hard hat. This equipment will protect against potential hazards such as falling objects, sharp edges, and sparks. 2. Lifting and handling: Steel channels can be heavy and cumbersome. Thus, it is important to use proper lifting techniques, such as bending the knees and using the legs to lift rather than the back. Mechanical lifting devices, such as cranes or forklifts, should be utilized for heavier channels. 3. Secure storage and stacking: When not in use, steel channels should be stored in a designated area that is secure and stable. Stacking should be done carefully, ensuring that the channels are properly supported and will not topple over. 4. Cutting and welding precautions: When cutting or welding steel channels, proper ventilation is crucial to prevent the inhalation of fumes and gases. Adequate ventilation systems should be in place, and workers should wear appropriate respiratory protection when necessary. Fire-resistant curtains or shields should be used to prevent sparks from igniting nearby flammable materials. 5. Sharp edges and burrs: Steel channels can have sharp edges or burrs that can cause cuts or injuries. It is important to inspect and remove any sharp edges or burrs before working with the channels. Wearing cut-resistant gloves can also provide an additional layer of protection. 6. Tripping and slipping hazards: Steel channels can create tripping hazards if left unsecured on the ground. Workers should ensure that the work area is clear of any obstructions or debris that could cause slips or falls. 7. Training and supervision: All individuals involved in working with steel channels should receive appropriate training and supervision. This includes understanding proper handling techniques, safety protocols, and emergency procedures. Regular safety meetings and inspections should also be conducted to maintain a safe working environment. By considering these safety measures when working with steel channels, the risk of accidents, injuries, and material damage can be significantly reduced, ensuring a safer and more productive working environment.

- Q: Q235's steel plate and channel steel were rusted in the rain. The corrosion is not too serious, but it looks obvious. Will this product be rejected? Is there a standard in this respect?Please answer professionals, thank you.

- Steel plate surface defects are allowed to be cleaned and cleaned, but the minimum thickness of the steel plate shall be ensured. Grinding and cleaning should be smooth, without edges and corners. When welding is required, it shall be carried out according to the provisions of GB/T 14977.

- Q: Is channel steel expensive or angle expensive?

- Specific look at what type of equilateral angle iron, different specifications of the difference, the channel is also, 63*63 angle steel and 80 groove, usually about the same

- Q: What are the design considerations when using steel channels?

- When using steel channels, there are several design considerations to take into account. Firstly, it is important to consider the load-bearing capacity of the channels, ensuring they can adequately support the intended weight and forces. Additionally, the dimensions and shape of the channels should be carefully chosen to align with the structural requirements and desired aesthetic. The material properties of steel, such as its strength, durability, and resistance to corrosion, should also be considered to ensure long-term performance. Lastly, factors like fabrication and installation methods, as well as cost considerations, should be taken into account during the design process.

- Q: What is a steel channel?

- A steel channel, which is also known as a C-channel or U-channel, is a steel structural component that has the shape of a "C" or a "U." It is widely used in the construction and manufacturing industries for a variety of purposes. Steel channels are typically made from hot-rolled or cold-formed steel and are available in different sizes and thicknesses to meet various needs. The strength and support provided by the shape of a steel channel make it ideal for structural applications such as framing, bracing, and bearing heavy loads. It is commonly utilized to create beams, columns, and purlins in buildings, bridges, and other infrastructure projects. In manufacturing processes where strength and rigidity are crucial, steel channels are essential. They can be employed as frames, rails, or supports to ensure stability and durability in machinery, vehicles, and equipment fabrication. Moreover, steel channels can serve decorative purposes in architectural designs. They can be integrated into interior or exterior designs to add visual interest, create unique shapes, or achieve a modern industrial look. Overall, a steel channel is a versatile and dependable component that offers strength, support, and flexibility in diverse construction and manufacturing applications.

- Q: Can steel channels be used for stair stringers in commercial buildings?

- Yes, steel channels can be used as stair stringers in commercial buildings. Steel channels are often preferred for their strength, durability, and load-bearing capabilities, making them suitable for supporting staircases in high-traffic areas such as commercial buildings. Additionally, steel channels can be easily fabricated and installed, providing a reliable and long-lasting solution for stair stringers in these settings.

- Q: Can steel channels be used in multi-story buildings?

- Multi-story buildings can indeed utilize steel channels. These steel channels, also referred to as C-channels or structural channels, are commonly employed in construction due to their robustness and endurance. They offer structural reinforcement and are frequently employed as framing components in numerous applications, including multi-story buildings. Steel channels possess a combination of lightweight and strength, rendering them ideal for multi-story buildings where weight plays a critical role. Their fabrication and installation are simple, which reduces construction time and expenses. Furthermore, steel channels exhibit excellent resistance to fire, corrosion, and other environmental factors, ensuring the long-term stability and safety of the building. Within multi-story buildings, steel channels can be employed as beams, columns, or bracing elements to distribute the load and provide stability. They can withstand the weight of floors, walls, and roofs, while also enduring dynamic forces such as wind and seismic loads. Through meticulous engineering and design considerations, steel channels can efficiently manage the vertical and horizontal loads that arise in multi-story buildings. Moreover, steel channels can seamlessly integrate with other structural systems, such as steel frames or reinforced concrete, to establish a sturdy and adaptable building structure. Their versatility allows for a broad range of design possibilities, accommodating different architectural styles and functional requirements. In conclusion, steel channels are a suitable option for multi-story buildings due to their strength, durability, and versatility. They offer structural support, resist environmental factors, and can be easily integrated into the building's framework.

Send your message to us

Hot Rolled JIS U-channel Carbon Steel HIgh Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords