Hot Rolled D-bar with Many Sizes

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offeringDeformed Steel Bar at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Deformed bar is widely used in buildings, bridges, roads and other engineering construction. Big to highways, railways, bridges, culverts, tunnels, public facilities such as flood control, dam, small to housing construction, beam, column, wall and the foundation of the plate, deformed bar is an integral structure material. With the development of world economy and the vigorous development of infrastructure construction, real estate, the demand for deformed bar will be larger and larger..

Product Advantages:

OKorder's Deformed Steel Bar are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Chemical Composition: (Please kindly find our chemistry of our material based on HRB400 as below for your information)

Grade | Technical data of the original chemical composition (%) | ||||||

C | Mn | Si | S | P | V | ||

HRB400 | ≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physical capability | |||||||

Yield Strength (N/cm²) | Tensile Strength (N/cm²) | Elongation (%) | |||||

≥400 | ≥570 | ≥14 | |||||

Packaging & Delivery of Wire Rod Q235:

Packaging Detail: products are packed in coil and then shipped by container or bulk vessel

Each coil weight: 2-3MT

Delivery Detail: within 45 days after received deposit or LC.

Label: to be specified by customer, generally, each bundle has 1-2 labels

Trade terms: FOB, CFR, CIF

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: What makes stainless steel stainless?

A2: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q3: Can stainless steel rust?

A3: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

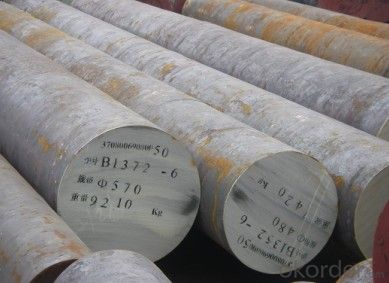

Images:

- Q: Can steel round bars be used for making molds?

- While steel round bars can be utilized in mold production, they may not be the most customary or optimal choice of material. Typically, steel round bars find application in structural or support roles. In the realm of mold fabrication, other materials such as silicone, aluminum, or specific steel molds are generally favored. These alternatives provide superior resistance to heat, flexibility, and convenience for molding purposes. Nevertheless, if the steel round bars are appropriately machined, shaped, and treated, they can still serve in fashioning uncomplicated molds for specific applications. However, prior to employing steel round bars, it is crucial to consider the mold's specific requirements, including the material being molded, the temperature and pressure conditions, and the desired final product finish.

- Q: How do you identify the grade of a steel round bar?

- The grade of a steel round bar can be identified through several methods. One way is to check the markings or labels on the bar itself. Manufacturers often stamp or engrave the grade directly onto the surface of the bar. These markings typically include information such as the grade designation (e.g., 304, 316, 4140), which represents the specific alloy composition, and may also include additional details such as the heat or lot number. Another method is to refer to the mill test certificate (MTC) that accompanies the steel round bar. The MTC provides comprehensive information about the composition, mechanical properties, and other relevant specifications of the material. The MTC is usually issued by the steel mill or supplier and can be requested upon purchase. Moreover, visual inspection and physical testing can help identify the grade of a steel round bar. Visual inspection involves observing the bar's appearance, texture, and color. Different grades of steel may exhibit distinct characteristics, such as a shiny or matte finish, specific surface treatments, or variations in color due to different alloying elements. Physical testing methods, such as tensile or hardness testing, can provide further confirmation of the steel grade. These tests measure the mechanical properties of the material, such as its strength, ductility, and hardness. By comparing the test results with known standards and specifications for different steel grades, one can determine the grade of the round bar. In summary, to identify the grade of a steel round bar, one can check for markings on the bar, refer to the mill test certificate, visually inspect the bar, and perform physical tests to assess its mechanical properties.

- Q: What are the specifications and standards for steel round bars?

- The specifications and standards for steel round bars vary depending on the intended use and industry requirements. However, there are some general specifications and standards that apply to most steel round bars. Firstly, the dimensions of steel round bars are typically specified in terms of diameter, length, and tolerance levels. The diameter can range from a few millimeters to several inches, and the length can vary as per the customer's needs. The tolerance levels indicate the allowable deviation from the specified dimensions and ensure the bars meet the desired accuracy and consistency. In terms of material composition, steel round bars are predominantly made from carbon steel, alloy steel, or stainless steel. The specific grade and composition of the steel will depend on the application, such as structural, construction, automotive, or aerospace. These grades are established by various organizations, such as the American Society for Testing and Materials (ASTM) or the International Organization for Standardization (ISO), and they define the chemical composition, mechanical properties, and other characteristics of the steel. Regarding mechanical properties, steel round bars must meet certain standards to ensure their strength, ductility, and resilience. These properties include tensile strength, yield strength, elongation, hardness, impact resistance, and more. The standards for these mechanical properties are specified by relevant organizations like ASTM or ISO, and they provide guidelines for manufacturers and users to ensure the bars are suitable for their intended applications. Surface finish is another important aspect of steel round bars. The standard surface finish options include black, peeled, ground, polished, or chrome-plated, among others. These finishes affect the appearance, corrosion resistance, and ability to withstand wear and tear. Furthermore, steel round bars may need to adhere to specific standards for heat treatment, such as annealing, quenching, or tempering, to enhance their mechanical properties or improve their machinability. Overall, the specifications and standards for steel round bars encompass dimensions, material composition, mechanical properties, surface finish, and heat treatment requirements. These standards ensure that steel round bars meet the necessary quality, performance, and safety criteria for their designated applications. It is crucial for manufacturers, suppliers, and end-users to be aware of these specifications and standards to ensure the appropriate selection and use of steel round bars.

- Q: How are steel round bars stored?

- Steel round bars are typically stored in a vertical position, either stacked on racks or placed in specially designed shelves or racks. These storage methods ensure that the bars are well-supported and easily accessible for transportation and use. Additionally, steel round bars are often bundled or strapped together to prevent them from rolling or becoming disorganized.

- Q: What are the common sizes of steel round bars?

- The specific application and industry standards determine the varying common sizes of steel round bars. Depending on these factors, the sizes can range from 1/4 inch to 24 inches in diameter. The availability of these sizes is often in increments of 1/8 inch or 1/4 inch. It is worth noting that the sizes may differ based on the country or region. Moreover, metric sizes are also an option, with diameters generally ranging from 6mm to 600mm. The extensive selection of steel round bar sizes enables a wide range of applications across different industries.

- Q: Can steel round bars be used in the production of forgings?

- In the production of forgings, steel round bars can be utilized. These round bars are commonly employed as the primary materials in forging procedures. To shape them, the round bars are heated to a specific temperature and then subjected to diverse forging techniques like hammering, pressing, or rolling. Through the application of heat and pressure during the forging process, the mechanical properties of the steel are improved, rendering it stronger and more enduring. Steel round bars are highly suitable for forging production as they ensure a consistent and uniform shape, guaranteeing that the final product adheres to the required specifications. Furthermore, steel round bars offer versatility in terms of their size, grade, and composition, allowing for a wide range of applications across various industries such as automotive, aerospace, and construction.

- Q: What are the different shapes available in steel round bars?

- There are several different shapes available in steel round bars, including round, square, hexagonal, and octagonal.

- Q: How do steel round bars compare to concrete round bars?

- Steel round bars are typically stronger and more durable than concrete round bars. Steel has a higher tensile strength and can withstand greater loads and stresses. Concrete round bars, on the other hand, are more commonly used for their resistance to corrosion and fire. Both materials have their own advantages and applications, but steel round bars are generally preferred for their superior strength and versatility in various construction projects.

- Q: What is the maximum length of a steel round bar that can be manufactured?

- The maximum length of a steel round bar that can be manufactured is dependent on various factors such as the manufacturing capabilities, equipment, and transportation limitations. However, in general, steel round bars can be manufactured in lengths ranging from a few meters to up to 12 meters or more.

- Q: How do steel round bars perform in high-temperature environments?

- Steel round bars generally perform well in high-temperature environments. The performance of steel round bars in high-temperature conditions can be attributed to their high melting point and excellent heat resistance properties. Steel has a relatively high melting point compared to other materials, allowing it to withstand elevated temperatures without losing its structural integrity. Furthermore, steel round bars possess excellent thermal conductivity, which allows them to dissipate heat efficiently, minimizing the risk of deformation or structural failure. This property makes steel round bars suitable for applications where heat is generated, such as in industrial processes or high-temperature equipment. In addition to its high melting point and thermal conductivity, steel also demonstrates good mechanical strength at high temperatures. It retains its load-bearing capacity and dimensional stability, ensuring that it can withstand the stresses and strains imposed on it in high-temperature environments. However, it is important to note that the performance of steel round bars in high-temperature conditions may be influenced by the specific grade of steel used. Different grades of steel have varying compositions and alloying elements which can affect their performance at elevated temperatures. It is crucial to select the appropriate grade of steel that is specifically designed for high-temperature applications to ensure optimal performance and longevity. Overall, steel round bars are a reliable and durable choice for use in high-temperature environments due to their high melting point, excellent thermal conductivity, and mechanical strength.

Send your message to us

Hot Rolled D-bar with Many Sizes

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords