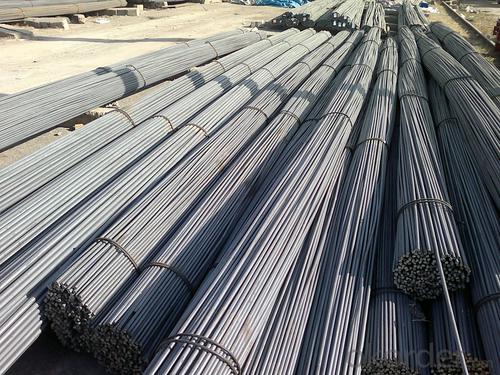

hot rolled round bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Steel Grade: | Standard: | Dimensions: | |||

| Place of Origin: | Brand Name: | Model Number: | |||

| Technique: | Application: | Alloy Or Not: | |||

| Special Use: | Type: | LENGTH: | |||

| COMMODITY: | SPEC: | SIZE: |

Packaging & Delivery

| Packaging Detail: | Packing Term: Bulk Packing Or Container. |

| Delivery Detail: | Within 30-45 days as of the date of contract signing |

Specifications

ROUND BAR (S45C,S20C,SS400,A36)

1.Length:6m to 12m

2.Grade:Q235/SS400/S20C/S45C

Remarks:

1.Origin / Manufacturer: China

2.Port of Loading: Tianjin Port,China

3.Packing Term: Bulk Packing Or Container

4.Measurement of Weight: By Theoretical Weighting

5.Certificate:ISO9001,CIC,BV,SGS

- Q: The difference between 304 stainless steel round bar and bright round bar

- Stainless steel rounds are not required on the surface. They may come with black leather. They may be pickling surfaces or cold drawn or polished surfaces;Stainless steel bright round steel refers to polished surface or cold drawn surface round steel.304 is the brand, and the surface quality has nothing to do with.

- Q: What are the advantages of using nickel-alloy steel round bars?

- There are several advantages of using nickel-alloy steel round bars: 1. High strength and durability: Nickel-alloy steel round bars are known for their superior strength and durability. They can withstand high levels of stress and provide excellent resistance to corrosion, making them ideal for applications in harsh environments. 2. Enhanced temperature resistance: Nickel-alloy steel round bars have excellent temperature resistance properties, allowing them to maintain their strength and integrity even at elevated temperatures. This makes them suitable for use in high-temperature applications such as aerospace, power generation, and petrochemical industries. 3. Improved corrosion resistance: Nickel-alloy steel round bars exhibit exceptional corrosion resistance, making them highly resistant to rust and oxidation. This characteristic makes them ideal for use in marine environments, chemical plants, and other applications where exposure to corrosive substances is common. 4. Excellent mechanical properties: Nickel-alloy steel round bars possess excellent mechanical properties such as high tensile strength, toughness, and ductility. This enables them to withstand heavy loads and impacts without deformation or failure, making them suitable for use in critical structural applications. 5. Versatility and adaptability: Nickel-alloy steel round bars can be easily machined, forged, and welded, allowing for greater versatility in manufacturing processes. They can be shaped and formed into various sizes and dimensions to meet specific application requirements, making them highly adaptable to different industries. 6. Cost-effective solution: While nickel-alloy steel round bars may have a higher initial cost compared to other materials, their long-term cost-effectiveness makes them a preferred choice for many industries. Their resistance to corrosion and wear reduces maintenance and replacement costs, ultimately resulting in significant cost savings over time. In conclusion, the advantages of using nickel-alloy steel round bars lie in their high strength, enhanced temperature resistance, improved corrosion resistance, excellent mechanical properties, versatility, adaptability, and cost-effectiveness. These qualities make them a reliable and efficient choice for a wide range of applications in various industries.

- Q: Can steel round bars be used in the hydraulic industry?

- Certainly, the hydraulic industry can make use of steel round bars. Renowned for their robustness, endurance, and immunity to corrosion, steel round bars prove to be ideal for a wide range of applications within the hydraulic industry. They find utility in the production of hydraulic cylinders, pistons, and other components necessitating exceptional tensile strength and dependability. Moreover, steel round bars can be conveniently machined and fashioned into diverse dimensions and specifications, ensuring they align with the precise requirements of hydraulic systems. In essence, owing to their exceptional mechanical characteristics and adaptability, steel round bars remain a favored choice in the hydraulic industry.

- Q: What are the different heat treatment processes for steel round bars?

- There are several heat treatment processes for steel round bars, including annealing, normalizing, quenching, tempering, and hardening. Annealing involves heating the steel to a specific temperature and then slowly cooling it to relieve internal stresses and improve its machinability. Normalizing is a similar process, but the cooling is done in still air to achieve a more uniform structure. Quenching involves rapidly cooling the steel from a high temperature to increase its hardness, while tempering is a subsequent process that reduces the brittleness caused by quenching through controlled reheating. Hardening is a process that involves heating the steel to a high temperature and then rapidly cooling it to achieve maximum hardness.

- Q: What are the different types of steel round bar surface treatments used in the aerospace industry?

- The aerospace industry utilizes various surface treatments for steel round bars to enhance performance and durability. These treatments are carefully designed to meet the industry's strict standards. Some commonly employed treatments in the aerospace industry are as follows: 1. Passivation: This treatment eliminates iron particles and contaminants from the steel round bar's surface. It prevents corrosion and enhances the material's overall corrosion resistance. 2. Shot Peening: Shot peening involves bombarding the steel round bar's surface with small metallic shots. This treatment induces compressive stress on the surface, thereby improving the material's fatigue strength and resistance to stress corrosion cracking. 3. Electroplating: Electroplating is a widely used surface treatment in the aerospace industry. It involves depositing a layer of metallic coating onto the steel round bar through an electrochemical process. This treatment enhances corrosion resistance, wear resistance, and aesthetic appearance. 4. Anodizing: Anodizing is an electrolytic passivation process commonly employed for aluminum alloys, but it can also be used for steel round bars. This treatment forms a thick, durable, and corrosion-resistant oxide layer on the surface, improving resistance to wear, corrosion, and scratching. 5. Nitriding: Nitriding is a surface hardening treatment that involves diffusing nitrogen into the steel round bar's surface. This treatment enhances surface hardness, wear resistance, and fatigue strength. 6. Chemical Conversion Coating: Chemical conversion coating forms a thin, protective layer on the steel round bar's surface. This coating enhances corrosion resistance and provides a suitable base for subsequent paint or coating applications. These examples demonstrate some of the various steel round bar surface treatments employed in the aerospace industry. Each treatment offers distinct advantages and is selected based on specific application requirements, including corrosion resistance, wear resistance, fatigue strength, and aesthetic appearance.

- Q: Can steel round bars be used for making mining equipment?

- Certainly! Mining equipment can indeed be made using steel round bars. These bars, owing to their exceptional strength, durability, and resistance to wear and tear, are widely utilized in the manufacturing process of various mining equipment. They are particularly suitable for applications that demand robust and heavy-duty machinery, such as drilling rigs, excavators, crushers, and conveyor systems employed in the mining industry. The adaptability of steel round bars enables them to be machined, welded, and shaped into diverse forms and sizes, thus facilitating the customization of mining equipment to cater to specific requirements. Moreover, steel round bars exhibit remarkable resilience in mining environments, enduring exposure to abrasive substances, extreme temperatures, and substantial loads.

- Q: Can steel round bars be used in the fabrication of machinery?

- Certainly, machinery fabrication can indeed utilize steel round bars. In the manufacturing industry, steel round bars are widely employed for a multitude of purposes, including the creation of machinery and equipment components. They possess numerous favorable qualities that render them suitable for this application. To begin with, steel round bars offer exceptional strength and durability. They are renowned for their high tensile strength, enabling them to withstand heavy loads and resist deformation. This strength is crucial in machinery fabrication, as the components must endure the stresses and forces encountered during operation. Moreover, steel round bars possess excellent machinability, allowing them to be easily shaped and formed into desired machinery components. This versatility permits the creation of intricate and complex machine parts. Furthermore, steel round bars exhibit remarkable resistance to corrosion and wear, which is vital in machinery fabrication. Machinery often operates in harsh environments or comes into contact with substances such as chemicals, oils, or abrasive materials. The corrosion and wear resistance of steel round bars ensure that the fabricated machinery can endure these conditions and maintain optimal performance over time. Lastly, steel round bars are readily available and cost-effective. They can be easily obtained from suppliers and manufacturers, making them a practical and economical choice for machinery fabrication. Overall, steel round bars are a favored and dependable material for machinery fabrication. Their strength, machinability, resistance to corrosion and wear, as well as their availability, make them an ideal option for creating durable and high-performing machine components.

- Q: What are the different types of corrosion-resistant steel round bars?

- There are several different types of corrosion-resistant steel round bars available in the market. Some of the commonly used types include: 1. Stainless Steel Round Bars: Stainless steel is a popular choice for corrosion-resistant applications due to its high resistance to rust and corrosion. It contains chromium, which forms a protective oxide layer on the surface of the steel, preventing further corrosion. 2. Duplex Stainless Steel Round Bars: Duplex stainless steel is a type of stainless steel that contains a balanced combination of austenite and ferrite microstructures. This gives it excellent corrosion resistance, high strength, and good weldability. 3. Nitronic Stainless Steel Round Bars: Nitronic stainless steel is a high-performance alloy that offers superior corrosion resistance, high strength, and good ductility. It contains nitrogen, which enhances its resistance to pitting and crevice corrosion. 4. Alloy Steel Round Bars: Alloy steel is a type of steel that is alloyed with various elements to improve its properties. Some alloy steels, such as corrosion-resistant alloys (CRA), are specifically designed to resist corrosion in harsh environments. These alloys typically contain elements such as chromium, nickel, and molybdenum. 5. Aluminum Round Bars: While not technically steel, aluminum round bars are often used in applications where corrosion resistance is essential. Aluminum forms a protective oxide layer on its surface, which helps prevent corrosion. It is particularly suitable for applications where weight is a concern. 6. Copper-Nickel Round Bars: Copper-nickel alloys, such as Cu-Ni 90/10 and Cu-Ni 70/30, are widely used in marine and offshore applications due to their excellent resistance to seawater corrosion. These alloys have high strength, good ductility, and exceptional resistance to biofouling. These are just a few examples of the different types of corrosion-resistant steel round bars available. The choice of material depends on the specific application requirements, environmental conditions, and budget considerations. It is important to consult with a materials engineer or specialist to select the most suitable corrosion-resistant steel round bar for a particular application.

- Q: What's the difference between round steel and screw steel? Which is cheaper than steel on the market these days?

- Round bar is divided into three parts: hot rolling, forging and cold drawing. Standard Specification for hot rolled round steel is 5.5-250 mm. Of which: 5.5-25 mm of small round bars, commonly used as steel, bolts and various mechanical parts, larger than 25 millimeters of round steel, mainly for the manufacture of machinery parts. Round steel has many kinds of materials, such as: Q195, Q235, 10#, 20#, 35#, 45#, Q215, Q235, 304, 316, 20Cr, 40Cr, 20CrMo, 35CrMo, 20CrMnTi, 5CrMnMo, etc...

- Q: What are the different types of steel round bar surface treatments for improved wear resistance?

- There are several different types of steel round bar surface treatments that can be applied to improve wear resistance. These treatments are designed to enhance the hardness, toughness, and overall durability of the steel, making it more resistant to wear and corrosion. Some of the most common surface treatments for steel round bars include: 1. Nitriding: This treatment involves exposing the steel to a nitrogen-rich environment at high temperatures. This forms a hard nitride layer on the surface, which improves wear resistance and provides enhanced hardness. 2. Carburizing: Carburizing is a process that involves introducing carbon into the surface of the steel to create a high-carbon layer. This layer increases hardness and wear resistance, making it suitable for applications that require high strength and durability. 3. Induction hardening: Induction hardening is a heat treatment process that selectively hardens the surface of the steel. This is achieved by heating the steel using an induction coil and then rapidly quenching it. The resulting hardened layer provides excellent wear resistance while maintaining the toughness of the core. 4. Shot peening: Shot peening involves bombarding the steel surface with small metal or ceramic particles at high velocity. This process creates compressive stresses on the surface, which improves fatigue life and wear resistance. 5. Thermal spraying: In thermal spraying, a coating material is melted and sprayed onto the steel surface using a flame or plasma torch. This creates a protective layer that offers enhanced wear resistance and corrosion protection. 6. PVD/CVD coatings: Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD) coatings involve depositing a thin layer of material onto the steel surface. These coatings provide excellent wear resistance, low friction, and improved corrosion protection. 7. Hard chrome plating: This process involves electroplating a layer of chromium onto the steel surface. Hard chrome plating offers high hardness, wear resistance, and corrosion protection. It's important to note that the choice of surface treatment depends on the specific application requirements and the type of wear resistance needed. Each treatment has its own advantages and limitations, and it is crucial to consider factors such as cost, environmental impact, and performance characteristics when selecting the most suitable treatment for a given steel round bar.

Send your message to us

hot rolled round bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords