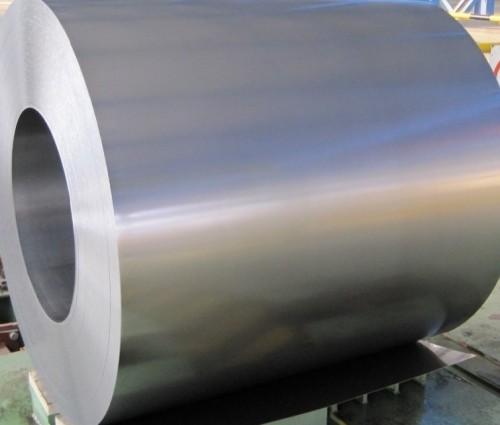

Hot Rolled Based Galvanized Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

ASTM A653M CS-B Z120, REGULAR SPANGLE, CHROMATED & UNOILED

SIZE (MM) MOQ (MTS)

1.50*1219*C 60

1.80*1219*C 60

2.00*1219*C 60

2.30*1219*C 60

2.50*1219*C 60

2.80*1219*C 60

3.00*1219*C 60

COIL ID: 610MM

COIL WEIGHT: 9-15MTS

PAYMENT: 100% LC AT SIGHT OR T/T WITH 20% DOWNPAYMENT & BALANCE AGAINST INVOICE & PACKING LIST

CARGO READNIESS: 30 DAYS AFTER LC ISSUING DATE OR T/T DOWNPAYMENT

SHIPMENT: BY BREAK BULK VESSEL

VALIDITY: 3 WORKING DAYS

- Q: Nickel is ferro magnetic in nature. But when it is added with stainless steel, it makes stainless steel non-magnetic. What is the structural changes happened with the presence of nickel?

- All stainless steel is non magnetic.

- Q: so I am trying to drill holes in stainless steel shelving to hang something but my drill wont make any more than a small dent in the steel. I bought a bit for hard metals but it didn't do any better. I have an admittedly small drill (9.6v). is that the problem? do I just need a more powerful drill? any serious advice is appreciated. thanks

- When machining stainless you need a sharp tool and an abrasive cutting compound for the best results.Most tools will slide on the stainless rather than cut into it. Stainless is very soft and it stretches rather than cuts. Try to keep the bit cool, but a special cutting compound is advised.

- Q: How are steel coils tested for quality?

- Steel coils are tested for quality through a variety of methods, including visual inspections, measurements of dimension and weight, and mechanical tests such as tensile strength and hardness. Additionally, non-destructive testing techniques like ultrasonic or magnetic particle testing may be used to detect any potential defects or flaws within the coils. These comprehensive testing procedures ensure that the steel coils meet the required quality standards before they are used in various industries.

- Q: I want to know if Diamond is stronger than Steel.

- Diamond is harder than steel, as diamond can scratch steel, but steel can't scratch diamond. However, I think steel is more structurally stable than diamond. Besides, how can you afford diamond girders, not even mentioning the impossibility of making a diamond that large.

- Q: steel bollard poles?

- There those short yellow post's the are too short to see when you back into them.

- Q: What are the different methods of testing the mechanical properties of steel coils?

- There are several methods for testing the mechanical properties of steel coils. Some commonly used methods include tensile testing, hardness testing, impact testing, and bend testing. Tensile testing measures the strength and ductility of the steel by applying a tensile force until it breaks. Hardness testing determines the resistance of the steel to indentation or scratching. Impact testing measures the ability of the steel to withstand sudden forces or shocks. Bend testing evaluates the flexibility and resistance to cracking of the steel by bending it to a specific angle. These methods help assess the quality and performance of steel coils in various applications.

- Q: is a 1962 steel penny worth anything?

- 1962 D Penny

- Q: I would like to buy a new cold steel recon 1 folding knife. My concern is the knife is made in Taiwan, will the quality of blade/overall make is lower quality compare with those made in US/JAPAN? The plan is use as an EDC, any good suggestion with similar style? Most important to me is reliability, 2)sharpness, 3) maintance than 4)cost. Anyone can point me into right direction? Please share, Thanks in advance.

- I recently bought the same weapon and am really impressed. There is no decline in quality and it arrived sharp enough to shave with. I rank upon the finer knives that I own. I would not hesitate to use it in a defensive situation (or offensive).

- Q: How are steel coils processed for specific applications?

- Steel coils are processed for specific applications through a series of carefully planned steps. The process begins with the selection of the appropriate grade and thickness of steel, which is determined based on the requirements of the end application. Once the steel coils are received, they undergo a series of processing steps to transform them into the desired product. The first step in processing steel coils is known as uncoiling, where the coil is unwound and straightened. This ensures that the coil is flat and ready for further processing. The uncoiled steel is then cleaned to remove any dirt, oil, or rust that may be present on the surface. This is typically done through a process called pickling, which involves immersing the steel in a bath of acid to remove any impurities. After cleaning, the steel undergoes various shaping processes depending on the desired application. This can include processes such as slitting, where the coil is cut into narrower strips, or shearing, where it is cut into specific lengths. These shaping processes are often performed using specialized machinery that can handle the high strength and thickness of steel. Once the steel has been shaped, it may undergo additional processes to enhance its properties. For example, it may be heat treated to increase its strength or hardness, or it may undergo a coating process to improve its corrosion resistance. Coating processes can include techniques such as galvanizing, where the steel is coated with a layer of zinc, or painting, where it is coated with a layer of paint. Finally, the processed steel coils are inspected for quality and undergo any necessary finishing processes. This can include processes such as trimming the edges to remove any irregularities, or applying protective coatings to prevent damage during transportation or storage. Overall, the processing of steel coils for specific applications is a complex and carefully controlled process. It involves a combination of shaping, cleaning, coating, and finishing processes to ensure that the steel meets the required specifications and is ready for use in various industries such as automotive, construction, and manufacturing.

- Q: What is the difference between hot rolled and cold rolled steel coils?

- The main difference between hot rolled and cold rolled steel coils is the process by which they are made. Hot rolled steel coils are produced by heating the steel above its recrystallization temperature, allowing it to be easily shaped and formed. This process results in a rougher surface finish and less precise dimensions. On the other hand, cold rolled steel coils are produced by further processing hot rolled coils through a series of rolling mills at room temperature. This process results in a smoother surface finish, tighter tolerances, and improved mechanical properties.

Send your message to us

Hot Rolled Based Galvanized Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords