Gpc143041 Hot Rolled Aluminum Coils for Oil Tanker

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Hot Rolled Aluminum Coils for Oil Tanker

Alloy: 1050, 1060, 1100, 3003, 3004, 3005, 3105, 5005, 5052, 5083, 5754

2) Temper: Various status

3) Thickness: 0.3-150mm

4) Width: 300-1950mm

5) Length: Under9500mm/ Coil

6) Weight: 2.5-5.0 tons per coil

7) Dimensions and weight can be produced according to clients' specifications.

8) Inner Diameter: 505mm, 605mm

9) Packing: Export standard, wooden pallet.

10) Delivery time: 20 days

11) Minimum order quantity: 5 tons per size.

12) The term of payment: T/T, irrevocable L/C at sight.

13) Surface: Bright

14)Origin: China

2. Application of Hot Rolled Aluminum Coils for Oil Tanker

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Hot Rolled Aluminum Coils for Oil Tanker

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

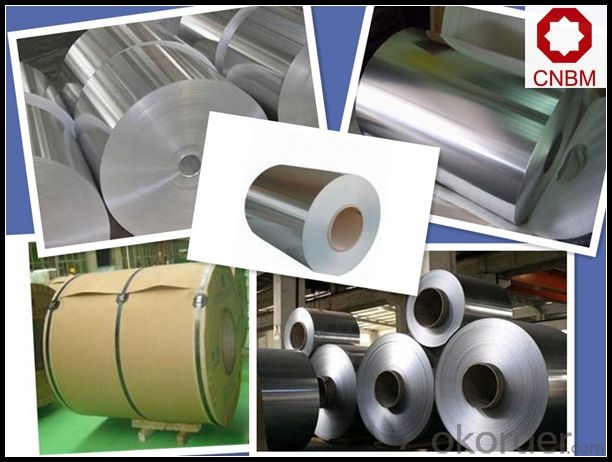

5. Image of Hot Rolled Aluminum Coils for Oil Tanker

6. Package and shipping of Hot Rolled Aluminum Coils for Oil Tanker

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: my text says aluminium does not corrode much as a passive aluminium oxide layer is formed on it.Well other metals such as sodium adn potassium also form oxides. Why dont their oxides prevent further oxidation ?

- Not sure. Maybe because Na K are more active than Aluminum.

- Q: What is the formula to calculate the wall thickness of aluminum coil?

- Aluminum coil thickness*aluminum coil width*aluminum coil curl*aluminum density (the density of aluminum alloy: 2.73, the density of pure aluminum: 2.71)

- Q: Can you create a tank, AFV, IFV etc. from aluminium or is this just a stupid idea that would kill everyone inside?

- Sure. The Vickers Mk 7 export tank had a turret of aluminum with composite armor layered over and mounted on a Leopard II hull. The M113 armored personel carrier, the most produced armored vehicle since WWII was made from aluminum as have been many other light armored vehicles. The protection these vehicles provide is limited to small arms fire however. Aluminum can't keep out large caliber projectiles and spalls badly against HEAT ammunition.

- Q: What's the color coated aluminum roll?

- The so-called color coated aluminum coil, refers to the surface of Aluminum Alloy the coloring process, because Aluminum Alloy properties is very stable, not easy to be corroded, the general surface after special treatment can ensure that at least 30 years do not fade, because of its low density, high hardness, weight of unit volume of metal materials is the lightest. The color of aluminum is a new material recently emerged in the field of the plastic doors and windows, and compared, the biggest advantage is that the degree of firmness and color changing, There is nothing comparable to this, and never faced steel have always been questioned "toxic" two words. Therefore, in high-grade market doors and windows, sunshine rooms, balcony packaging and other fields are widely used. Now, color coated aluminum rolls have become one of the most popular top decorative materials. It is a kind of green with environmental protection, durability and beauty. It has the following advantages as decorative materials unmatched by other products: uniform color, bright and smooth, durable, strong adhesion, acid and alkali corrosion resistance, weathering resistance, decay resistant friction resistance, resistance to ultraviolet radiation, strong weatherability.

- Q: Are aluminum coils more cost-effective compared to other materials like copper?

- Yes, aluminum coils are generally more cost-effective compared to other materials like copper. There are several reasons for this. Firstly, aluminum is a more abundant metal than copper, which makes it cheaper to produce. This abundance also means that aluminum prices tend to be more stable and less prone to fluctuations in the market, further contributing to its cost-effectiveness. Secondly, aluminum coils have a lower density compared to copper coils, resulting in lighter weight units. This lighter weight not only reduces transportation and installation costs but also makes aluminum coils easier to handle and maneuver during the manufacturing process. Additionally, aluminum coils have excellent thermal conductivity properties, which means they can effectively transfer heat. This allows for more efficient cooling or heating systems, resulting in lower energy consumption and operating costs over time. Moreover, aluminum has a higher resistance to corrosion compared to copper, making it more durable and requiring less maintenance. This increased lifespan of aluminum coils reduces replacement and repair costs, further enhancing their cost-effectiveness. Lastly, aluminum coils are recyclable, and the recycling process requires significantly less energy compared to producing new aluminum. This aspect contributes to the overall sustainability and cost-effectiveness of aluminum coils. Overall, considering the lower production costs, lighter weight, superior thermal conductivity, increased durability, and recyclability, aluminum coils are indeed more cost-effective compared to other materials like copper.

- Q: What are the bending and forming capabilities of aluminum coils?

- Aluminum coils have excellent bending and forming capabilities due to the inherent properties of aluminum as a malleable and ductile material. Aluminum is known for its high strength-to-weight ratio, which allows it to be easily shaped and formed without compromising its structural integrity. When it comes to bending, aluminum coils can be bent into various shapes and angles without fracturing or cracking. The flexibility of aluminum allows it to be formed into tight curves or gentle bends, making it suitable for a wide range of applications. This flexibility is particularly advantageous in industries such as construction, automotive, and aerospace, where curved or complex shapes are often required. In terms of forming, aluminum coils can be easily manipulated into different forms, including flat sheets, tubes, or intricate profiles. This versatility makes aluminum coils highly sought after in industries where customization and design flexibility are important. Furthermore, aluminum coils can undergo various forming processes such as roll forming, stamping, and deep drawing, allowing them to be transformed into different products with precise dimensions and tolerances. These forming capabilities make aluminum coils a preferred choice for manufacturing components, such as automotive body panels, roofing materials, heat exchangers, and structural elements. Overall, the bending and forming capabilities of aluminum coils are exceptional, making them an ideal choice for applications that require flexibility, durability, and design versatility.

- Q: Are aluminum coils suitable for food processing applications?

- Yes, aluminum coils are suitable for food processing applications. Aluminum is a versatile and widely used material in the food industry due to its various beneficial properties. It is corrosion-resistant, non-toxic, lightweight, and has excellent thermal conductivity. These properties make aluminum coils ideal for food processing applications such as cooking, storage, and transportation. Aluminum coils can be used in the production of cookware, food packaging, and food processing equipment. They are often used in the manufacturing of pots, pans, baking sheets, and other kitchen utensils. The high thermal conductivity of aluminum ensures even heat distribution, allowing for efficient cooking and preventing hot spots. Furthermore, aluminum coils are commonly used in food packaging, including cans for beverages and canned foods. Aluminum cans are lightweight, durable, and provide a barrier against light, moisture, and air, ensuring the preservation and quality of the food products. In addition, aluminum coils are suitable for food processing equipment such as heat exchangers, evaporators, and refrigeration systems. The corrosion-resistant nature of aluminum prevents contamination and ensures the hygiene and safety of the food being processed. It is important to note that aluminum coils used in food processing applications should meet specific food-grade standards to ensure they do not leach any harmful substances into the food. These standards include regulations set by the Food and Drug Administration (FDA) in the United States and similar organizations worldwide. Overall, aluminum coils are well-suited for food processing applications due to their corrosion resistance, non-toxicity, lightweight, and excellent thermal conductivity. They are widely used in the food industry for cooking, packaging, and processing equipment, contributing to the safety and efficiency of food production.

- Q: What are the potential applications of coil-stucco aluminum coils?

- Coil-stucco aluminum coils have various potential applications due to their unique properties. They are commonly used in the construction industry for roofing, siding, and facades, as their stucco surface provides enhanced durability and weather resistance. These coils are also used in the manufacturing of appliances, such as refrigerators and ovens, as well as in the automotive industry for trim and decorative purposes. Furthermore, coil-stucco aluminum coils can be utilized in the packaging industry for containers and cans due to their lightweight and corrosion-resistant nature.

- Q: How are aluminum coils coated for corrosion resistance?

- Aluminum coils are coated for corrosion resistance through a process known as coil coating. This involves applying a protective coating onto the surface of the aluminum coils to prevent oxidation and corrosion. The coating is typically a combination of primer and topcoat that is applied using various methods such as coil coating lines or spray applications. The coating acts as a barrier, protecting the aluminum from environmental factors such as moisture, chemicals, and UV radiation, thereby enhancing its durability and extending its lifespan.

- Q: This question asks for methods to prevent corrosion on aluminum coils during storage or transportation.

- <p>To prevent corrosion on aluminum coils during storage or transportation, follow these steps: 1. Store the coils in a dry, clean environment to avoid moisture and dirt. 2. Use protective wrapping or covers to shield the coils from moisture and contaminants. 3. Ensure proper ventilation in storage areas to prevent condensation. 4. Avoid stacking coils directly on the ground; use pallets or racks to keep them off damp surfaces. 5. Handle the coils carefully to prevent scratches or damage that could lead to corrosion. 6. Regularly inspect the coils for signs of corrosion and address any issues promptly. 7. Consider using anti-corrosion coatings or treatments on the coils if they will be stored for extended periods. By following these guidelines, you can minimize the risk of corrosion and maintain the integrity of your aluminum coils.</p>

Send your message to us

Gpc143041 Hot Rolled Aluminum Coils for Oil Tanker

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords