Aluminum Coil Slitting Machine for Sale - Hot Rolled Aluminium Coil AA1070 for Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Factory Supply Hot Rolled Aluminium Coil AA1070 for Building

characteristics | Application |

1) Super peeling strength | 1) Building exterior curtain walls |

2) Excellent surface flatness and smoothness | 2) Decoration and renovation additions for old buildings |

3) Superior weather, corrosion, pollutant resistance | 3) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies |

4) Even coating, various colors | 4) Shop door decorations |

5) Fireproof, excellent heat and sound insulation | 5) Advertisement board display platforms and signboards |

6) Superior impact resistance | 6) Wallboards and ceilings for tunnels |

7) Lightweight and easy to process | 7) Industrial materials, materials for vehicles and boats |

2. Application of Factory Supply Hot Rolled Aluminium Coil AA1070 for Building

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels, column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Factory Supply Hot Rolled Aluminium Coil AA1070 for Building

• Our goods quality is top, the surface is smooth, and every steel coil

• No Joint, No Bends, no spots, no roller marks.

• MTC will be provided with goods, third part inspection is acceptable, for example, SGS, BV. Etc

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

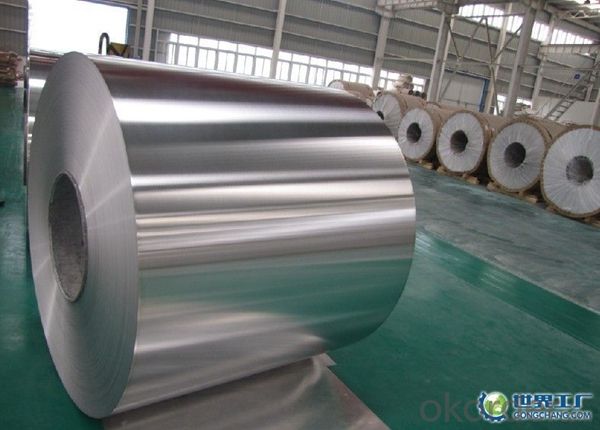

5. Image of Factory Supply Hot Rolled Aluminium Coil AA1070 for Building

6. Package and shipping of Factory Supply Hot Rolled Aluminium Coil AA1070 for Building

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: The canoe is aluminum. It has some paint remaining on it from what i am assuming is the original factory paint. The paint is just in patches, so my question is do i sand only where the paint is, or the whole canoe? Will sanding the aluminum damage it? Or should I not sand it at all, and just use paint stripper? After getting the old paint off, what kind of primer should i use? or is it not necessary to prime? What kind of paint should I use? I plan on it being multi tone(a leafy camo, of olive drab, flat black, and a gray tone).

- ...if you paint it black, it'll never tip.

- Q: Difference between aluminium roll gate and iron roll gate

- Structurally, there is no difference, but the aluminum roll gate weight is light, the motor needs little effect, save power; and the iron roll gate weight, motor power, electricity, but the door of high strength, better safety performance.

- Q: What is the shear strength of aluminum coils?

- The shear strength of aluminum coils varies depending on the specific alloy and temper. However, on average, aluminum coils have a shear strength ranging from 110 MPa to 190 MPa.

- Q: How to calculate the wall thickness with the gross weight of aluminum coil known?

- Gross weight*density=volume volume÷(aluminum sheet *width)=thickness

- Q: What is the typical heat transfer coefficient for aluminum coils?

- The typical heat transfer coefficient for aluminum coils can vary depending on various factors such as the specific application, coil design, and operating conditions. However, a commonly observed range for the heat transfer coefficient of aluminum coils is around 50 to 250 W/m2K.

- Q: a) Although Aluminium is a reactive metal, it is used to make door frames and window frames.b) Although Aluminium conducts heat, it is used to make blankets, which are good thermal insulators.

- a) true b) false

- Q: How do aluminum coils contribute to reduced maintenance costs?

- Aluminum coils contribute to reduced maintenance costs primarily due to their exceptional durability and resistance to corrosion. Unlike other metals, such as copper, aluminum coils are specifically designed to withstand harsh environmental conditions, including exposure to moisture, salt, and chemicals. This resistance to corrosion ensures that the coils remain intact and functional for extended periods, minimizing the need for frequent repairs or replacement. Additionally, aluminum coils are lightweight, making them easier to handle and install, which reduces labor costs associated with maintenance activities. Furthermore, their high thermal conductivity allows for efficient heat transfer, resulting in increased energy efficiency and lower utility bills. Overall, the use of aluminum coils in HVAC systems helps to reduce maintenance expenses and prolong the lifespan of the equipment, making them a cost-effective choice for both residential and commercial applications.

- Q: Are aluminum coils suitable for insulation jacketing?

- Yes, aluminum coils are suitable for insulation jacketing. Aluminum is a popular choice for jacketing material due to its excellent thermal properties, durability, and corrosion resistance. It is widely used in various industries, including HVAC, oil and gas, and petrochemical, for insulating pipe systems and equipment. Aluminum coils provide a protective covering around insulation materials, preventing moisture ingress and maintaining thermal efficiency. Additionally, their lightweight nature makes them easy to install and transport. Overall, aluminum coils are a reliable and effective solution for insulation jacketing applications.

- Q: Is it safe to use steel wires for making jewelry or decorative items, and are there any potential health hazards associated with it?

- <p>Using steel wires for jewelry or decorations generally poses minimal health risks when used properly. However, there are a few considerations: allergic reactions can occur in individuals sensitive to nickel, which is often found in stainless steel. Additionally, improper use or sharp edges can lead to cuts or injuries. It's important to ensure that the steel is of high quality and that any jewelry made is smooth and free of sharp points to minimize the risk of injury. Regular cleaning and maintenance are also recommended to prevent any potential health risks associated with bacteria buildup or skin irritation.</p>

- Q: What is the typical thermal expansion coefficient for aluminum coils?

- The typical thermal expansion coefficient for aluminum coils is around 23 x 10^-6 per degree Celsius.

Send your message to us

Aluminum Coil Slitting Machine for Sale - Hot Rolled Aluminium Coil AA1070 for Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords