Hot Dipped Galvanized Wing Nut Dia 26mm

- Loading Port:

- XINGANG

- Payment Terms:

- TT

- Min Order Qty:

- 2000 Unit/Units pc

- Supply Capability:

- 5000 pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The steel formwork scaffolding part-Hot Dipped Galvanized Wing Nut Dia 26mm:

1.Name: The formwork scaffolding accessories— wing nut

2.Material: casting steel, ZG25

3.Surface treatment: Raw/ HDG

4.Specification: as clients' drawing

5.Use: suit for formwork scaffolding

Specifications of Hot Dipped Galvanized Wing Nut Dia 26mm:

1) Scaffolding wing nut ,Q235 Steel material

2) Surface: Hot dipped galvanized

3) Dia.: various sizes are available

4) Weight: Standard or as customers request

Name | Wing Nut |

Materail | Ductile Cast Iron |

Surface finished | zinc plate |

Size | Dia 26mm |

Weight | 0.35kg |

Supply Ability | 5000pieces per month |

MOQ | Negotiation |

Payment Terms | L/C,T/T,Western Union |

Delivery Time | 20-45days or as your quantity |

OEM service | Available |

Standard | BS1139,EN74 |

Details of Hot Dipped Galvanized Wing Nut Dia 26mm:

1. Raw Material: ductile iron or forged carbon steel

2. Weight: Standard or as customers request

3. Standards: BS1139, EN74 class A & B

4. Working load: minimum 17kn

Specifications of Hot Dipped Galvanized Wing Nut Dia 26mm:

Ductile wing nuts

2.Material: ductile iron

3.Various specifications available.

4.Surface: Plain, white galv. or color galv.

Details of Hot Dipped Galvanized Wing Nut Dia 26mm:

Electroplate Surface

Weight: 1-1.8kg

Ductile Iron Material

Different kinds of design as per your requirement

Material:ductile iron

Diameter:26mm

Surface treat:zinc plate

working load: minimum 17kn

With different kinds of design

High Quality Competitive Price

cast iron tie rod nut

1. We also call it Alignment coupler

2. It used to entighten the connection of each two formwork panels

3. Increase the strength of formwork

4. This BFD Coupler Panel Formwork clamp's infill area up to 100mm

5. Adjust size:94mm to 225mm

6. Material is high grade steel,Q235

7. Surface treatment: Elec.galvanized (Yellow or white)

8. Application: PERI formwork system

Packaging & Delivery of Hot Dipped Galvanized Wing Nut Dia 26mm:

Packaging Detail:Plywood case or pallet or as your request.

Delivery Detail:10-30 days after receive remittance

We are specializes in designing & manufacturing of various kinds of formwork systems, including H20 timber-beam formwork, aluminum formwork, steel (aluminum)- frame formwork etc.

All the equipments & formwork systems produced by CNBM are compliant with the National level quality standard, and wins great reputation for their endurable performance in worldwide markets.

- Q: How to manage the construction equipment at the construction site

- Personnel training, accreditation of staff training, including job skills training and personnel safety education and training

- Q: What are the general requirements for fire protection facilities?

- Before the start of the project, the temporary fire protection facilities at the construction site should be designed and the temporary fire protection facilities of the construction site should be used as the construction site.

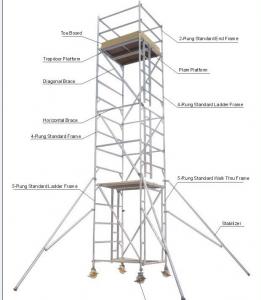

- Q: What are the aspects installation of the construction site?

- Production area (tool room, shed, duty room, temporary road, temporary wall, temporary water and so on

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 1987 |

| Annual Output Value | Below US$1 Million |

| Main Markets | China; United States; Britain; Japan; Germany; Israel |

| Company Certifications | GB/T19001-2008/ISO9001:2008 Quality Certification |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Xingang |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | 10-20 people |

| Language Spoken: | Chinese; English |

| b) Factory Information | |

| Factory Size: | Above 3,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

Hot Dipped Galvanized Wing Nut Dia 26mm

- Loading Port:

- XINGANG

- Payment Terms:

- TT

- Min Order Qty:

- 2000 Unit/Units pc

- Supply Capability:

- 5000 pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords