Hot Dip Galvanized Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

AISI,JIS,GB,BS,DIN,API,EN,ASTM

Technique:

Hot Rolled,Cold Rolled,Cold Drawn,ERW,Forged,Saw,Extruded,EFW,Spring

Shape:

U Channel,Square,C Channel,Hexagonal,Round,Rectangular,Oval,LTZ

Surface Treatment:

Galvanized,Coated,Copper Coated,Color Coated,Oiled,Dry,Chromed Passivation,Polished,Bright,Black,PVDF Coated

Steel Grade:

Q195,Q215,Q235,Q215B,Q235B,RHB335,HRB400,200 Series,300 Series,400 Series,600 Series,SS400-SS490,10#,20#,A53(A,B)

Certification:

ISO,SGS,CE

Thickness:

as required

Length:

as required

Net Weight:

as required

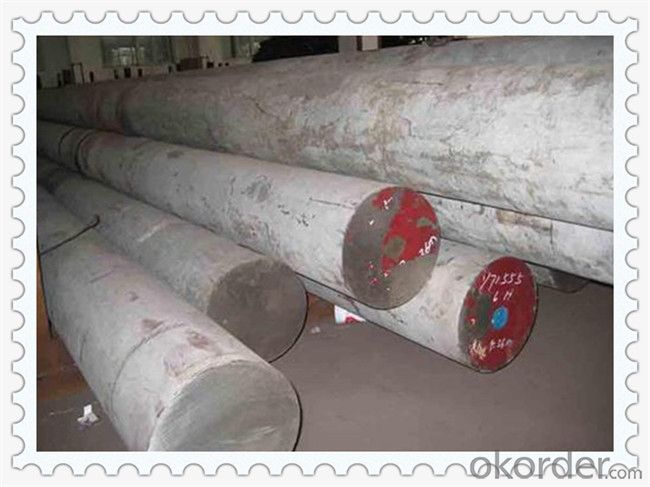

Hot Dip Galvanized Steel Round Bar

| ITEM | Hot dip galvanized (HDG) steel round bar/hot dip galvanized bar steel | ||||

| Standard: | GB,ASTM,BS,JIS | Dimensions: | 10-200mm | Grade: | Q235,SS400,A36,S45,ST37 |

| Place of Origin: | Tianjin China (Mainland) | Brand Name: | HXT | Zinc coating thickness grade | GR.60~85,400~600g/m2 |

| Type: | hot rolled & cold drawn | Application: | building ,construction,machiniary | Trade Terms: | FOB,CIF,CFR |

| Payment: | T/T,L/C | Certificate: | ISO9001:2000,SGS,BV | Package: | Standard export package |

| Delivery Time: | 7-10 workdays | Shipping Port: | Xingang,Tianjin,China | Wall Thickness: | 10-200mm |

| Length: | 2~12.5m,as required | Technique: | Hot dip galvanizing GB/T13912/ASTM A123 | Productivity: | 10000 tons/month |

| Hot-dip galvanized steel round bars produced from hot rolled steel round bar or the cold drawn round bar,with the hot dip galvanizing process.The hot dip galvanized steel round bar has very good corrosion resistance performace,it's widely used in the industry of building,construction,photovoltaic solar energy, lightning protection system,fabrication and machiniary. | |||||

| size | kg/m | size | kg/m | size | kg/m |

| 5.5 | 0.186 | 28 | 4.83 | 75 | 34.7 |

| 6 | 0.222 | 29 | 5.18 | 80 | 39.5 |

| 6.5 | 0.26 | 30 | 5.55 | 85 | 44.5 |

| 7 | 0.302 | 31 | 5.92 | 90 | 49.9 |

| 8 | 0.395 | 32 | 6.31 | 95 | 55.6 |

| 9 | 0.499 | 33 | 6.71 | 100 | 61.7 |

| 10 | 0.617 | 34 | 7.13 | 105 | 68 |

| 11 | 0.746 | 35 | 7.55 | 110 | 74.6 |

| 12 | 0.888 | 36 | 7.99 | 115 | 81.5 |

| 13 | 1.04 | 38 | 8.9 | 120 | 88.8 |

| 14 | 1.21 | 40 | 9.86 | 125 | 96.3 |

| 15 | 1.39 | 42 | 10.9 | 130 | 104 |

| 16 | 1.58 | 45 | 12.5 | 140 | 121 |

| 17 | 1.78 | 48 | 14.2 | 150 | 139 |

| 18 | 2 | 50 | 15.4 | 160 | 158 |

| 19 | 2.23 | 53 | 17.3 | 170 | 178 |

| 20 | 2.47 | 55 | 18.6 | 180 | 200 |

| 21 | 2.72 | 56 | 19.3 | 190 | 223 |

| 22 | 2.98 | 58 | 20.7 | 200 | 247 |

| 23 | 3.26 | 60 | 22.2 | 210 | 272 |

| 24 | 3.55 | 63 | 24.5 | 220 | 298 |

| 25 | 3.85 | 65 | 26 | 230 | 326 |

| 26 | 4.17 | 68 | 28.5 | 240 | 355 |

| 27 | 4.49 | 70 | 30.2 | 250 | 385 |

- Q: Can steel round bars be coated for improved aesthetics?

- Yes, steel round bars can be coated for improved aesthetics. Coating steel round bars can enhance their appearance by providing a more polished and visually appealing surface. There are various coating options available, such as powder coating, electroplating, or painting, which can be applied to steel round bars to achieve different aesthetic effects. These coatings not only enhance the appearance of the bars but also provide additional benefits such as corrosion resistance and durability. Therefore, coating steel round bars is a common practice to improve their aesthetics in various applications including architectural, decorative, and industrial purposes.

- Q: What are the different types of steel round bar alloys used in the aerospace industry?

- There are several different types of steel round bar alloys that are commonly used in the aerospace industry. These alloys are specifically designed to meet the demanding requirements of the aerospace sector, including high strength, corrosion resistance, and lightweight properties. 1. Stainless Steel: Stainless steel is one of the most popular alloys used in aerospace applications. It offers excellent corrosion resistance, high strength, and good heat resistance. This alloy is commonly used in aircraft components such as landing gear, fasteners, and engine parts. 2. Titanium Alloy: Titanium alloys are widely used in the aerospace industry due to their high strength-to-weight ratio. They offer excellent corrosion resistance, good fatigue strength, and can withstand high temperatures. Titanium alloys are commonly used in aircraft frames, engine components, and landing gear. 3. Aluminum Alloy: Aluminum alloys are lightweight and have good mechanical properties, making them suitable for aerospace applications. They offer good corrosion resistance and are often used in aircraft structures, wings, and fuselage components. 4. Nickel Alloy: Nickel alloys are known for their high strength and excellent resistance to extreme temperatures. They are commonly used in aerospace applications where resistance to heat, wear, and corrosion is critical, such as in turbine engines and exhaust systems. 5. High-Strength Low-Alloy (HSLA) Steel: HSLA steels are known for their high strength and good weldability. They offer good toughness and impact resistance, making them suitable for aerospace applications where strength and durability are essential, such as in landing gear and structural components. Overall, the aerospace industry utilizes a combination of these steel round bar alloys to meet the specific requirements of different components and applications. Each alloy offers unique properties that make it suitable for specific aerospace applications, ensuring the safety, reliability, and performance of aircraft in the highly demanding aerospace environment.

- Q: Can steel round bars be used in the automotive manufacturing industry?

- Yes, steel round bars can be used in the automotive manufacturing industry. They are often utilized for various applications, such as the production of engine components, suspension systems, and structural parts. Steel round bars offer excellent strength, durability, and machinability, making them suitable for meeting the demanding requirements of the automotive industry.

- Q: Can steel round bars be used for valve stem applications?

- Yes, steel round bars can be used for valve stem applications. Steel round bars are often used in various industrial applications, including valve stems, due to their strength, durability, and resistance to corrosion.

- Q: Will the three steel is steel? It is a steel bar?

- Your question is inaccurateThread steels are grade two, grade three, grade four, and even grade fiveFirst grade steel generally refers to the wire rod, also known as wire rod, is a ribbed steel bar

- Q: What are the advantages of using cobalt-alloy steel round bars?

- There are several advantages to using cobalt-alloy steel round bars in various industries and applications. Firstly, cobalt-alloy steel has exceptional strength and hardness, making it highly resistant to wear, corrosion, and high temperatures. This makes it suitable for demanding environments where other materials would fail or degrade quickly. Secondly, cobalt-alloy steel has excellent dimensional stability, meaning it maintains its shape and size even under extreme conditions. This makes it ideal for applications that require precise tolerances and minimal deformation, such as in the aerospace and automotive industries. Additionally, cobalt-alloy steel has excellent heat resistance, allowing it to retain its mechanical properties even at elevated temperatures. This makes it valuable in applications that involve high-speed machining, cutting tools, and turbine components. Moreover, cobalt-alloy steel round bars can be easily machined and fabricated, allowing for customization and versatility in various applications. Their high machinability and weldability make them suitable for use in manufacturing processes, such as forging, casting, and machining. Furthermore, cobalt-alloy steel round bars have excellent fatigue resistance, ensuring long-lasting performance and durability. This makes them suitable for applications that involve repetitive stress or cyclic loading, such as shafts, springs, and fasteners. Lastly, cobalt-alloy steel is known for its biocompatibility, making it suitable for medical and dental applications. It is commonly used in orthopedic implants, surgical tools, and dental instruments due to its corrosion resistance and biocompatibility properties. In summary, the advantages of using cobalt-alloy steel round bars include exceptional strength, hardness, and dimensional stability, as well as heat resistance, machinability, fatigue resistance, and biocompatibility. These qualities make them valuable in a wide range of industries and applications, offering reliability, durability, and performance.

- Q: Can steel round bars be used for making marine equipment?

- Yes, steel round bars can be used for making marine equipment. Steel is a versatile and durable material that is commonly used in the marine industry due to its strength, corrosion resistance, and ability to withstand harsh environmental conditions. Steel round bars can be machined, welded, and formed into various shapes and sizes to meet the specific requirements of marine equipment. They are commonly used for manufacturing marine components such as propeller shafts, rudders, anchor chains, and structural supports. Additionally, steel can be coated or treated to enhance its corrosion resistance, making it suitable for prolonged exposure to saltwater and other corrosive elements found in marine environments.

- Q: Can steel round bars be used in the agriculture industry?

- Steel round bars find extensive use in the agriculture industry, where they serve a multitude of purposes. Commonly employed in the construction of farm equipment, fencing, and building structures, steel round bars are renowned for their robustness and longevity, rendering them ideal for demanding tasks within the agricultural sector. Moreover, these bars exhibit exceptional resistance to harsh weather conditions and corrosion, thereby ensuring their enduring reliability and durability in agricultural settings. In essence, steel round bars emerge as a versatile and pragmatic option for the agriculture industry, owing to their immense strength, durability, and ability to withstand environmental factors.

- Q: What is the typical tolerance for diameter and length in steel round bars?

- The tolerance for diameter and length in steel round bars can vary depending on the industry standards and requirements specific to each sector. Generally, the tolerance for diameter in steel round bars is typically between +/- 0.005 and 0.010 inches. This means that the bar's actual diameter can deviate up to 0.010 inches from the specified diameter, either larger or smaller. Likewise, the tolerance for length in steel round bars is usually around +/- 0.125 to 0.250 inches. Consequently, the actual length of the bar can differ up to 0.250 inches from the specified length, either longer or shorter. It is essential to highlight that these tolerances can differ based on the intended application and the manufacturing industry's specific standards. Therefore, it is vital to refer to the relevant industry standards or the manufacturer's specifications to determine the precise tolerances required for a specific steel round bar.

- Q: What are the different types of steel round bar shapes?

- There are several different types of steel round bar shapes, including solid round bars, hollow round bars, threaded round bars, and precision ground round bars.

Send your message to us

Hot Dip Galvanized Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords