Hot dip Galvanized Steel Coil/GI/HDGI ASTM A653 0.13mm - 2.0mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Hot dip Galvanized Steel Coil/GI/HDGI ASTM A653 0.13mm - 2.0mm:

1) Standards: JIS G3302 1998 / ASTM A653M / A924M 1998/ DIN EN10143/GBT 2518-2008

2) With excellent weather resistance

3) Suitable for partitions, vending machinery, decks, scaffolding, purlin, gurdrail, suspension bar for ceiling and so on

4) Specification: SPCC, SGCC, SGCH, SGCD, SGHC, (CS, SS, DDS)

5) Thickness: 0.14mm-50mm

6) Width: 20mm - 1250mm

7) Zinc coating: Z08, Z12, Z18, Z20, Z22, Z25, Z27.Z100

8) Surface finish: Regular spangle, minimized spangle, zero spangle

9) Surface treatment: Chromating treatment, anti-finger print

10) Inner diameter: 508mm / 610mm

11) Outer diameter: 2, 000mm max .

2.Specifications of Hot dip Galvanized Steel Coil/GI/HDGI ASTM A653 0.13mm - 2.0mm:

Steel Grade : SPCC SGCC DX51D Q235 Q195

Type : Steel Coil

Surface Treatment : Galvanized

Technique : Cold Rolled Or Hot rolled

Tianjin,China

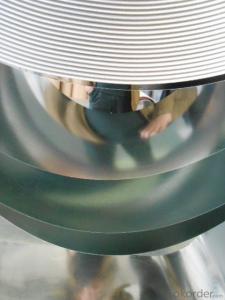

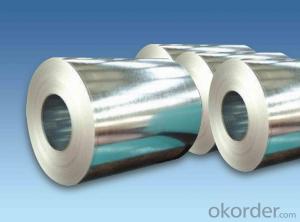

3.Hot dip Galvanized Steel Coil/GI/HDGI ASTM A653 0.13mm - 2.0mm Images:

4.Hot dip Galvanized Steel Coil/GI/HDGI ASTM A653 0.13mm - 2.0mm Specification:

Base metal | Cold rolled steel coil,full hard cold rolled steel coil,Black cold rolled steel coil |

Material | DX51D+Z,CSB,S280GD,S320GD,S350GDSGCC |

Grade: | Commercia.Quality(CGCC,DX51D,DC01,SPCC), Structure.quality(S280GD,S320GD,S350GD). Deep.drawing.quality(DX52D,DX53D,DX54D,DX56D) |

Standard | ASTM A653 CS/B,JIS G3302,DIN EN 10142,EN10327 |

Applications | Advertising,building trade,home electrical, Electrical industry,decoration,office furniture |

Thickness | 0.18mm-1.5mm |

Tolerance | +/-0.03mm |

Zinc layer | A40,A60,G60,G90,G115,G140,G165. Z12,Z18,Z22,Z25,Z27,Z35. Z60,Z80,Z100,Z120,Z150,Z180,Z220,Z275,Z350 |

Width | 600mm,750mm,762mm,914mm,1000mm,1219mm,1200mm,1250mm,1500mm |

Length | 1.5m,2.0m,2.438m,2.44m,2.5m,3m.,3.5m,4m,4.5m,5m |

Surface treatment | Chromated,oiled/unoiled,skinpassed,Chromated+oiled |

Surface state | Regular spangle,mini spangle,zero spangle, skinpassed |

Coil weight | 4-8tons |

ID | 508mm or 610mm |

Packing | Export standard seaworthy packing. Waterproof paper+steel sheet+bundle with steel strips(3-4pcs) |

Delivery | Based on the quantity. |

Shipment | Bulk vessel or container (FCL/LCL) |

Payment | T/T or LC at sight |

Loading port | Main port of China,Shang hai,Qingdao,Dalian,Tianjin etc. |

Yield strength | 285Mpa-305Mpa |

Tensile strength | 340Mpa-370Mpa |

5.PACKING:

6.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What are the common defects found in steel coils?

- Some common defects found in steel coils include surface defects like scratches, indentations, and pits, as well as internal defects such as cracks, lamination, and segregation. Other defects can include edge wave, coil breaks, and coil set.

- Q: My musical saw has, despite my best efforts, got little patches of rust on it. How Do I go about removing the rust without spending too much on rust-removal products and without affecting the properties of the steel?

- I would suggest rust removal by electrolysis. Search youtube for that. It probably will not affect the metal but there are no guarantees. I would run a test on another metal. Also this process can be dangerous because hydrogen gas is a by-product - remember not to smoke or be cooking nearby! The Easy way is with BlackStar Rust Remover. It will turn the metal black and convert the rust to metal which can then be painted or left black.

- Q: What are the different coil packaging machine configurations used for steel coils?

- There are various coil packaging machine configurations utilized for steel coils, each tailored to specific coil sizes, weights, and packaging needs. 1. The horizontal coil packaging machine is designed for smaller steel coils. It is typically equipped with a conveyor system that transports the coil horizontally throughout the packaging process. It may incorporate automatic coil centering, wrapping, and strapping features to guarantee secure and efficient packaging. 2. The vertical coil packaging machine is suitable for larger and heavier steel coils. It is designed to package coils in a vertical position and often includes a rotating arm or turntable for wrapping and securing the coil with strapping. Vertical machines have a higher throughput capacity and can handle coils of various sizes and weights. 3. The ring coil packaging machine is specifically designed for large and heavy steel coils. It comprises a rotating ring structure that surrounds the coil and moves up and down while wrapping and securing it with stretch film or other packaging material. Ring coil packaging machines are versatile, accommodating coils of different diameters and weights, making them suitable for various coil packaging requirements. 4. The eye-to-sky coil packaging machine is intended for steel coils that need to be packaged in an eye-to-sky orientation. It typically features a wrapping station that rotates the coil while applying stretch film or other packaging material. This configuration ensures proper protection and stability during transportation and storage. 5. The eye-to-horizontal coil packaging machine is designed for steel coils that need to be packaged in an eye-to-horizontal orientation. It includes a conveyor system that transports the coil horizontally while applying stretch film or other packaging material. Eye-to-horizontal machines can handle coils of different sizes and are designed to provide secure packaging for easy handling. In conclusion, the choice of coil packaging machine configuration depends on factors such as coil size, weight, packaging requirements, and production throughput. Different configurations offer distinct features and capabilities to ensure efficient and secure packaging of steel coils.

- Q: I need to penetrate steel on my car but don't know which bit to use. Are there special bits for steel?

- it's go through steel buddy. But i would imagine that a majority of your standard bits out there will do it. I know there are material specific bits but i would say if you didn't have real expensive drill bits I would try pretty much any of them. If you are talking about the frame of your car or something that thick, then a heavy-duty would be necessary. Don't go drop a lot of money on a diamond bit unless you just keep tearing them up trying to drill through whatever it is you're trying to accomplish. Ive seen wood bits go through some heavy duty metal, so give it a try and save some money.

- Q: What are the common coil widths available for steel coils?

- The common coil widths available for steel coils vary depending on the specific application and industry requirements. However, there are several standard coil widths that are commonly available in the steel industry. These include: 1. 24 inches (approximately 610 mm): This is a common coil width used for various applications, including automotive manufacturing, construction, and general engineering. 2. 36 inches (approximately 914 mm): This wider coil width is often used in the construction industry for roofing and siding materials. 3. 48 inches (approximately 1219 mm): This wider coil width is commonly used in manufacturing processes where larger steel sheets are required, such as in the production of appliances, HVAC systems, or industrial machinery. 4. 60 inches (approximately 1524 mm): This wider coil width is typically used for specialized applications in industries such as automotive manufacturing, aerospace, or shipbuilding. It is important to note that while these are some of the more common coil widths, steel coils can be produced in custom widths to meet specific customer requirements. Additionally, the availability of coil widths may vary depending on the steel mill or supplier.

- Q: How are steel coils used in the manufacturing of furniture?

- Steel coils are used in the manufacturing of furniture to provide structural support and stability. They are commonly used in the construction of sofa frames and mattress bases to ensure durability and longevity. The coils are typically formed into springs, which are then incorporated into the furniture to enhance comfort and provide a responsive seating or sleeping surface.

- Q: I am trying to clean up a stainless steel back splash and some kitchen appliances that have brown spots that look like rust spots. I was able to remove most of them with stainless steel cleaner but does anyone know any tricks?

- I recommend using a product called Bar Keepers Friend. It is a household powder cleaner like Ajax but it has a mild abrasive that works on stainless steel and other surfaces. It will remove the rust without harming the stainless steel.

- Q: I have heard that heating the steel and applying oil will help with corrosion, and will give that aged look. I would like to know finishes available without painting. thanks

- No, I don't think the oil will do what you want. I have heated and quenched metal in oil several times (to harden it) and it did not give a finish to steel. I have heard of heating steel to a high temperature (red) and putting powdered sulfur on it, it will make a black finish. BUT, sulfur stinks and you would not do this indoors. And I don't know what the results would be like for indoor use. At the hardware store, you can find something like POR (paint on rust), a brand name of rust neutralizer. There are others. You spray it on (or paint) and it will turn rust into a glossy black material. Other than that, I think paint is your best option. Check out the new finishes they have now, if you haven't checked, they have come a long way. If you let them dry completely (in the sun) the spray can finishes are very durable. Good luck! Ooops, I forgot about gun finishes. Yes, some are blue, you might be thinking of that, but that is only if you put several coats on. One coat might do it. Plus, there are other colors, such as black (see the parkerizing link on the list). Here is a good company, they can be lots of help, too.

- Q: i bought an airsoft gun and it said steel recievers on it im not sure what that is

- Basically okorder / And so on and so on. Contrary to what the first answerer said, steel receivers aren't that bad. They do give a bit of heft but they are quite durable, give a realistic feel, and don't break when you land on them by accident.

- Q: Hi can someone help me pleaseis there any available data for mechanical behaviour of recycled steel, i need to compare them with new steel.

- Most recycled steel is blended with new steel at the steel mill. Scrap steel that is reused directly doesn't change it properties because it has been used. That is unless it has been in certain environments such as ones with hydrogen, hydrogen sulfide etc. Then the steel can become brittle. You might look for information on the National Association of Corrosion Engineers (NACE). They have lots of information on metals and what causes problems.

Send your message to us

Hot dip Galvanized Steel Coil/GI/HDGI ASTM A653 0.13mm - 2.0mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords