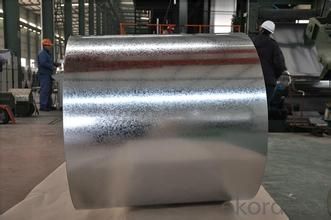

Hot-Dip Galvanized/ Aluzinc Steel in SGCC grade

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications.

Specifcation:

1.Mateials:SGCC,DX51D / DX52D /S250,280GD

2.Size:width:600-1250mm(900mm,1215mm,1250mm,1000mm the most common)

thickness:0.15-2.0mm

length:1000-6000mm,as your require

3.Zinc coating :60-180g( as required)

4.Coil id:508mm

5.Coil weight: 3-5MT(as required)

6. Surface:regular/mini/zero spangle, chromated, skin pass, dry etc.

Images:

We can ensure that stable quality standards are maintained, strictly meeting both market requirements and customers’ expectations. Our products enjoy an excellent reputation and have been exported to Europe, South-America, the Middle-East, Southeast-Asia, Africa and Russia etc.. We sincerely hope to establish good and long-term business relationship with your esteemed company.

- Q: were iron age weapons made of steel?

- No, the iron age was just iron. It was smelted down in open fires where temperatures can vary. There was a problem of not always being able to cook out all the impurities from the ore, which led to inconsistent strengths in finished products. People first discovered the properties and advantages of steel when charcoal (carbon) was added to smelted iron. I don't know when the first steel was made. But it must have been a more expensive process because it didn't appear in household products until around 1800. But I'm not sure on that.

- Q: How are steel coils used in the manufacturing of metal containers?

- Steel coils are used in the manufacturing of metal containers by being unrolled and shaped into the desired form using specialized machinery. These coils provide the necessary strength and durability to the containers, ensuring they can withstand the rigors of transportation and storage.

- Q: What are the different types of steel coil surface treatments for corrosion resistance?

- There are several different types of steel coil surface treatments that are used to enhance corrosion resistance. These treatments are applied to the surface of the steel coil to create a protective layer that prevents corrosion and extends the lifespan of the steel. Some of the common types of surface treatments for corrosion resistance include: 1. Galvanizing: This is one of the most popular and effective methods for protecting steel against corrosion. In this process, a layer of zinc is applied to the surface of the steel coil. The zinc acts as a sacrificial anode, corroding before the steel does, thus protecting it from rust and corrosion. 2. Chromate conversion coating: This treatment involves applying a chromate-based solution to the surface of the steel coil. The chromate forms a thin film on the steel, providing a protective barrier against corrosion. It also enhances the adhesion of paint or other coatings that may be applied later. 3. Phosphating: Phosphating is a process where a phosphate coating is applied to the steel coil. This coating provides excellent corrosion resistance by forming a chemical bond with the steel surface. It also improves the adhesion of subsequent coatings or paints. 4. Organic coatings: These coatings, such as paint or epoxy, are applied to the steel coil to create a barrier between the steel and the surrounding environment. They provide both corrosion resistance and aesthetic appeal. The choice of organic coating depends on the specific application and the desired level of corrosion protection. 5. Zinc-rich paint: Similar to galvanizing, zinc-rich paint contains a high concentration of zinc particles. When applied to the steel coil, the zinc particles provide sacrificial protection, preventing corrosion. This coating is often used in harsh environments or for steel coils that will be exposed to frequent moisture or saltwater. It is important to note that the choice of surface treatment depends on various factors such as the application, environment, budget, and required level of corrosion resistance. Consulting with a steel coil manufacturer or corrosion specialist is recommended to determine the most suitable treatment for a specific situation.

- Q: What is the standard length of steel coils?

- The standard length of steel coils can vary depending on the specific industry and application. However, a common standard length for steel coils is typically around 30 feet or 9.1 meters.

- Q: I want to purchase steel for construction purpose, What aspects should I keep in mind while deciding that which company should I contact for this?

- I'd keep in mind whether your potential supplier is close enough to still give you good service, and provide delivery when you need it. I'd want to contact as many local companies as possible, in order to get competitive bids. Then, I'd pick the lowest cost bids that I felt would still provide the service I needed. Most decisions of this sort, in the end, are based on price.

- Q: How are steel coils used in construction?

- Steel coils are commonly used in construction for a variety of applications, such as structural components, roof panels, and wall cladding. These coils are typically shaped and cut into specific lengths to meet the required dimensions of the construction project. They provide strength, durability, and versatility, making them an essential material for various construction purposes.

- Q: I'm buying a new set of steel plugs.I've heard things about streched ears and cold weather not being to good. do you think it would be bad to be wearing steal plugs?

- Personally, okorder They are spot on for sizing, they do customs, and amazing quality like i have never seen before and I have been through a lot of plugs. Hope this helps :)

- Q: Can steel coils be deep-drawn?

- Yes, steel coils can be deep-drawn. Deep-drawing is a metal forming process where a sheet or coil is drawn into a die cavity to create a three-dimensional shape. Steel coils, due to their high strength and ductility, are often used in deep-drawing applications to produce various products such as automotive parts, kitchen appliances, and containers.

- Q: I have a bottle like this* Can u make hot chocolate in it. Can i heat it.I wanna take hot Chocolate to school

- Stainless okorder /... on Hot Drink in Stainless Steel Water Bottle.

- Q: How are steel coils used in the manufacturing of wires?

- Steel coils are used in the manufacturing of wires by being fed into wire drawing machines, where they are gradually reduced in diameter through a series of dies. The steel coils serve as the initial raw material, providing the necessary strength and flexibility for the wires to be produced.

Send your message to us

Hot-Dip Galvanized/ Aluzinc Steel in SGCC grade

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords