Hot-dip Aluzinc Steel With High Quality Good Price China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Aluzinc Steel With High Quality Good Price China

1. Description of the Hot-dip Aluzinc Steel:

Hot-dip aluzinc steel structure is composed of aluminum-zinc alloy, consisting of 55% aluminum, 43% zinc and 2% at 600 ℃ silicon solidification temperature and composition, the entire structure is made of aluminum - iron - silicon - zinc, to form a dense quaternary crystals an alloy.

2.Applications of hot-dip aluzinc steel:

1)Building: roof, walls, garages, soundproof walls, pipes and modular housing.

2)Automotive: muffler, exhaust pipes, wiper accessories, fuel tank, truck boxes, etc.

3)Appliances: refrigerator back, gas stove, air conditioners, microwave oven, LCD frame,

3.Main Features of the Hot-dip Aluzinc Steel:

• Excellent corrosion resistance

•Surface coating

•Cost-effective

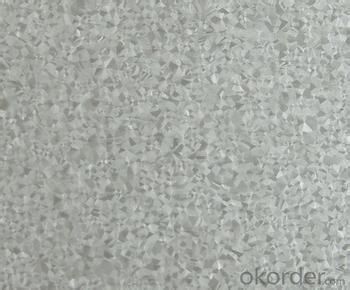

4.Hot-dip Aluzinc Steel Images

5.Hot-dip Aluzinc Steel Specification

AVAILABLE SPECIFICATION

HOT-DIP ALUZINC STEEL COILS | |||

COMMERCIAL QUALITY | ASTM A792M-06a | EN10327-2004 | JIS G 3321:2010 |

STRUCTURE STEEL | SS GRADE 230 SS GRADE 255 SS GRADE 275 SS GRADE 340 SS GRADE 550 | S220GD+AZ S250GD+AZ S280GD+AZ S320GD+AZ S350GD+AZ S550GD+AZ | SGLC400 SGLC440 SGLC490 SGLC570 |

6.FAQ of Hot-dip Aluzinc Steel

We have organized several common questions for our clients,may help you sincerely:

1.What advantages does your company have?

Cement : Annual capacity of 400 million tons, No. 1 in the world

Fiberglass: Annual capacity of 1 million tons fiberglass, No. 1 in the world.

Composite Materials — Carbon Fiber: Annual capacity of 10,000 tons PAN precursor and 4,000 tons carbon fiber, No. 1 in China

Glass: CNBM owns about 20 modern float glass product`ion lines, With annual capacity of 10 million square meters glass.

Commercial concrete: Annual capacity of 0.35 billion cubic meters, No. 1 in the world.

2.What advantages do your products have?

Firstly, our base material is of high quality, Their performance is in smooth and flat surface,no edge wave ,good flexibility.

Secondly, high quality zinc ingoats, 97.5% zinc,1.5% silicon,1% others, the same zinc coating measured by metal coating thickness or by zinc weight

- Q: What are the different methods of recoiling steel coils?

- There are several methods of recoiling steel coils, including the slitting method, the oscillating method, and the rewinding method.

- Q: what is the stucture of high carbon steel

- That is kind of a broad question because high carbon steel can cover a broad range and you did not mention the condition. But I will try to keep it simple. If it is in a wrought condition, it would likely be pearlite plus carbides along the grain boundaries., The atomic structure would be body centered cubic. Sometimes high carbon steel is spherodized annealed and that would be ferrite with lots of round carbides. The atomic structure would be body centered cubic. If it is quench and tempered, it would be martensite and would probably have noticeable carbides if the carbon content was high enough. The atomic structure would be body centered tetragonal

- Q: What are the common certifications required for steel coils?

- The common certifications required for steel coils depend on the specific industry and application of the coils. However, there are several widely recognized certifications that are commonly required. 1. ISO 9001: This certification ensures that the manufacturer has implemented a quality management system that meets international standards. It verifies that the manufacturer has the necessary processes and controls in place to consistently produce high-quality steel coils. 2. ISO 14001: This certification focuses on environmental management systems. It ensures that the manufacturer is committed to minimizing its environmental impact and reducing waste in the production process. 3. ISO 45001: This certification pertains to occupational health and safety management systems. It ensures that the manufacturer has implemented measures to protect the health and safety of its employees and stakeholders. 4. ASTM International Standards: The American Society for Testing and Materials (ASTM) has established various standards for steel coils. These standards cover aspects such as chemical composition, mechanical properties, and dimensional tolerances. Compliance with these standards ensures that the coils meet the specified requirements and are suitable for their intended use. 5. EN Standards: The European Committee for Standardization (CEN) has developed a set of standards for steel coils, known as EN standards. These standards cover similar aspects as ASTM standards but are specific to the European market. 6. JIS Standards: The Japanese Industrial Standards (JIS) are widely used in the steel industry in Japan and other countries in Asia. Compliance with JIS standards ensures that the coils meet the specific requirements of the Japanese market. 7. Product-specific certifications: Depending on the application of the steel coils, additional certifications may be required. For example, if the coils are intended for automotive use, certifications such as ISO/TS 16949 (Quality Management Systems for the Automotive Industry) may be necessary. It is important to note that the specific certifications required may vary depending on the region, industry, and customer requirements. Manufacturers should consult with their customers and industry standards organizations to determine the exact certifications necessary for their steel coils.

- Q: How are steel coils used in the manufacturing of transmission systems?

- Steel coils are used in the manufacturing of transmission systems to create various components such as gears, shafts, and bearings. These coils are often transformed into flat sheets or strips, which are then shaped and processed to form the required parts. The strength and durability of steel make it an ideal material for transmission systems as it can withstand the high stress and torque associated with transmitting power from the engine to the wheels efficiently and reliably.

- Q: How are steel coils used in the production of HVAC ducts?

- Steel coils are used in the production of HVAC ducts as they are rolled into a specific shape and size to form the main body of the duct. The coils are then cut and welded together to create a seamless and durable structure that can withstand the high temperatures and pressures associated with HVAC systems.

- Q: What are the dimensions of steel coils used in the HVAC industry?

- The dimensions of steel coils used in the HVAC industry can vary depending on the specific application and requirements. However, common dimensions for these coils typically range from 0.5 to 2.5 inches in thickness, 12 to 60 inches in width, and 100 to 600 feet in length.

- Q: What are the different types of steel coil slitting techniques?

- There are several types of steel coil slitting techniques, including rotary shear slitting, loop slitting, and oscillating slitting.

- Q: How do steel coils contribute to the agricultural industry?

- Steel coils play a vital role in the agricultural industry by serving as a key component in the production and maintenance of various agricultural machinery and equipment. These coils are primarily used in the manufacturing of farm equipment such as tractors, plows, harvesters, and irrigation systems. One of the significant contributions of steel coils is their durability and strength, making them ideal for agricultural applications. The coils are processed and formed into different shapes and sizes to create sturdy components that can withstand the harsh conditions and heavy workloads typically associated with farming operations. Steel coils are widely used in the construction of tractor frames, ensuring the structural integrity and stability of the vehicles. The coils are also utilized in the manufacturing of plow blades, providing the necessary strength to effectively cut through the soil and prepare the land for planting. Moreover, steel coils are crucial in the creation of harvester blades, enabling efficient harvesting and minimizing crop damage. In addition to machinery, steel coils are essential in the production of irrigation systems that are instrumental in agricultural practices. These systems require pipes and tubes that can withstand high water pressures and resist corrosion caused by the elements. Steel coils are processed into these pipes and tubes, ensuring their durability and longevity, thereby aiding in efficient water management and irrigation in fields. Furthermore, steel coils contribute to the agricultural industry by ensuring the safe storage and transportation of agricultural products. They are used in the construction of storage silos and grain bins, which provide secure and weather-resistant spaces for storing crops. Steel coils are also utilized in the fabrication of transportation containers such as trailers and trucks, ensuring the safe delivery of agricultural goods from farms to markets. In summary, steel coils have a significant impact on the agricultural industry. Their strength, durability, and versatility make them essential in the manufacturing of agricultural machinery, irrigation systems, storage facilities, and transportation containers. By providing reliable and efficient equipment, steel coils contribute to increased productivity, improved crop yields, and enhanced overall efficiency in the agricultural sector.

- Q: Help please.What atoms are there in steel?Like water is equals to 1 Oxygen atom + 2 Hydrogen atoms.Thnx 4 d help.

- Steel is an alloy consisting mostly of iron, with a carbon content between 0.2 and 1.7 or 2.04% by weight (C:1000–10,8.67Fe), depending on grade. Steel is Fe(iron) and Carbon alloy. These are the atoms in certain ratio that make up steel. Its not a molecule but alloy.

- Q: How are steel coils used in the manufacturing of railway equipment?

- Steel coils are used in the manufacturing of railway equipment as they are transformed into various components such as rail tracks, train wheels, and structural frames. These coils are processed through rolling mills to achieve the desired shape and strength required for the specific railway equipment.

Send your message to us

Hot-dip Aluzinc Steel With High Quality Good Price China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords