High Tensile Strength Interlock Biaxial Geogrids

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

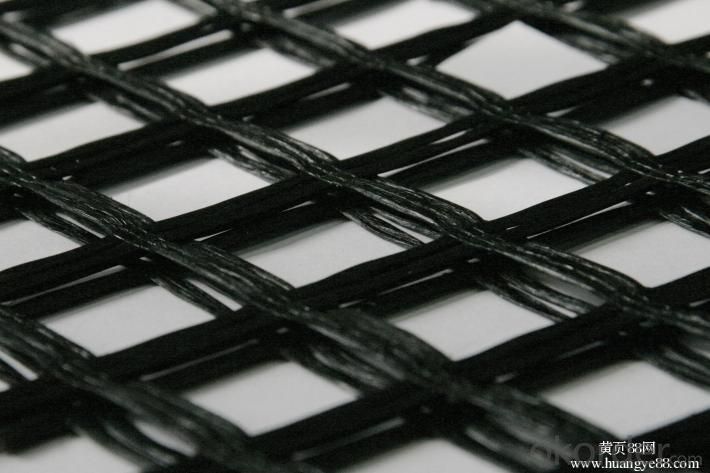

Structure of Fiberglass Geogrid

Fiberglass geogrid is A kind of planar mesh material using alkali-free fiberglass yarn as base body and

then coated with high quality modified asphalt.. The products after surface covering own the favorable property of alkali resistance and aging resistance

Main Features of the Fiberglass Geogri

High quality asphalt coation

Light weight, high tensile, corrosion resistance

Road maintenance and reinforcement

Packaging & Delivery

| Packaging Details: | PP bags or PE film. Or Packed as customers' requests. |

| Delivery Detail: | 10-20days after the contract is effective |

Fiberglass Images

Fiberglass Geogrid Specification

Converting old cement concrete road into composite road.

Restraining reflection cracking caused by block shrinkage.

Preventing and controlling the cracking caused by new and old combination and uneven settlement.

Road extension.

Reinforcement of soft soil foundation and overall strength of roadbed

Property | Test Method | TGSG 15-15 | TGSG 20-20 | TGSG 30-30 | TGSG 40-40 | |

Ultimate tensile strength(1) (kN/m) | MD |

ASTM D 6637 | 15 | 20 | 30 | 40 |

CD | 15 | 20 | 30 | 40 | ||

Elongation at maximum load (%) | MD | 13 | ||||

CD | 13 | |||||

Tensile strength at 2 % elongation (kN/m) | MD | 5 | 7.5 | 10.5 | 14 | |

CD | 5 | 7.5 | 10.5 | 14 | ||

Tensile strength at 5 % elongation (kN/m) | MD | 7 | 14 | 21 | 28 | |

CD | 7 | 14 | 21 | 28 | ||

Minimum Carbon Black | % | ASTM D 4218 | 2 | |||

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q: How about your company?

A:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q.Does your products have good qualitity?

A:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q:How long can we receive the products after purchase?

A:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: Are geogrids suitable for reinforcing railway ballasts?

- Yes, geogrids are suitable for reinforcing railway ballasts. Geogrids provide effective soil reinforcement and stabilization, enhancing the load-bearing capacity and overall performance of railway ballasts. They help distribute loads more evenly, reduce settlement and deformation, and improve the long-term stability of the ballast layer. Geogrids also help prevent lateral spreading of the ballast material, maintaining track alignment and reducing maintenance requirements. Overall, geogrids are a reliable and effective solution for reinforcing railway ballasts.

- Q: What kind of experiments need to be done to check geogrid

- Generally do tensile test, the main determination of 2%, 5% and 10% corresponding strength. Strict requirements for the deformation of the project, strictly speaking, but also to do creep test, but the creep experiment takes too long, most projects do not do.

- Q: What is the recommended spacing between geogrid layers?

- The recommended spacing between geogrid layers can vary depending on the specific application and design requirements. However, in general, a spacing of about 1 to 2 feet (30 to 60 centimeters) is often recommended. This allows for proper interlocking and interaction between the geogrid layers, ensuring optimal load distribution and stability. It is important to consult with a geotechnical engineer or follow the manufacturer's guidelines to determine the appropriate spacing for a particular project.

- Q: How do geogrids help in reducing the risk of differential settlement of structures?

- Geogrids help in reducing the risk of differential settlement of structures by providing reinforcement and improving the load-bearing capacity of the soil. They act as a stabilizing layer, distributing vertical and horizontal forces evenly, which prevents uneven settling of the foundation. This helps maintain the structural integrity of the building and minimizes the potential for damage or structural failure.

- Q: What are the benefits of using geogrids in roadways?

- The benefits of using geogrids in roadways include improved load-bearing capacity, reduced pavement thickness, increased stability and durability, prevention of cracking and rutting, enhanced drainage and erosion control, and cost savings in construction and maintenance.

- Q: What are the factors that affect the design and selection of geogrids for geosynthetic reinforcement of steep slopes?

- There are several factors that affect the design and selection of geogrids for geosynthetic reinforcement of steep slopes. These factors include the slope angle, soil type and properties, anticipated loads and stresses, project objectives, and budget constraints. Additionally, site-specific conditions such as climate, drainage, and vegetation should be considered. Properly considering these factors ensures that the selected geogrids are suitable for the specific slope reinforcement needs, providing stability, erosion control, and long-term durability.

- Q: I would like to ask what kind of railway construction materials?Under the trouble of experts who can help me explain these materials. I am engaged in the procurement of Railways in this regard, I want to rush to prepare the information

- Building conventional materials do not say, the following is only part ofWaterproof agentPrestressed steel strand

- Q: Where can I do three to the geogrid test?

- Currently did not find the corresponding three geogrid test specification, how to determine the direction of the three cells, how to load are not standardized

- Q: How do geogrids help in reducing construction equipment requirements?

- Geogrids help in reducing construction equipment requirements by providing soil stabilization and reinforcement. They act as a support structure, distributing loads and reducing the need for heavy machinery. This allows for cost-effective and efficient construction, minimizing the requirement for extensive equipment usage.

- Q: Geogrid test items: what is the point of the joint point of penetration

- It is not feasible for you to put the test item of waterproof material on the geogrid.

Send your message to us

High Tensile Strength Interlock Biaxial Geogrids

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords