High Temperature Resistance Silica Chopped Fiberglass Fabric Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Image:

Product Description & Application:

It is high temperature resistant product.Mixed a ratio of organic fiber in the chopped silica fiberglass and put into fiberglass or stainless steel wire as reinforcement to spun the yarn,and then woven into the cloth.(stainless steel wire or fiberglass reinforced)

Application:

As the external insulation layer for industrial furnaces and other external heat preservation and heat insulation for a variety of mechanical equipment and pipeline;

As welding spark cloth for building,ship,large construction equipment industry;

Fireproof and heat indulation for rail vehicle,vehicle transportation insulation parts;

Can be processed into the fire-proof curtain in the building ,fireproof garment( covered aluminum),fireproof gloves,fireproof shoes,etc.

Product Capability:

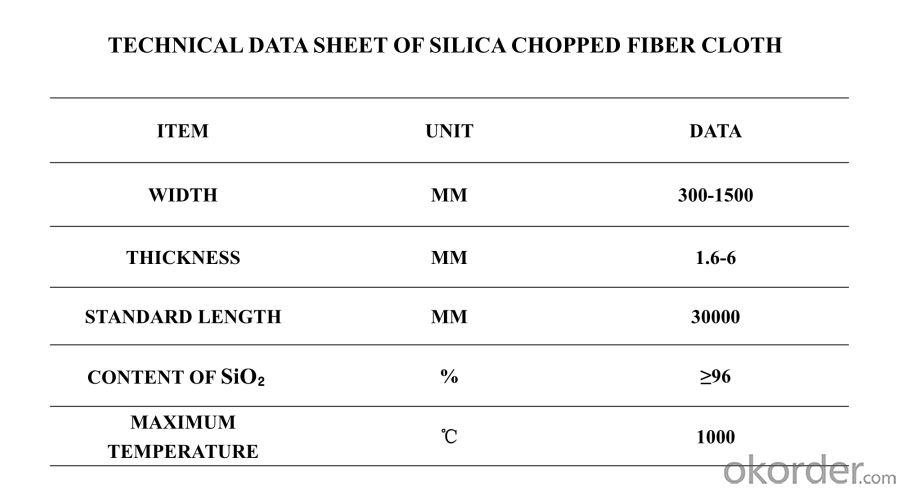

SiO2>=96%;

Compared with the traditional high silica fiberglass cloth,the advantage of this cloth is that can be reinforced with stainless steel wire,have strong resistance performance,can be folded,thick and light weight,high air tightness;

The skin irritation is very small,no dust,can replace the traditional ceramic fiber cloth;

Higher temperature resistant,insulation,low heat conduction rate;

High thermal and chemical stability,good dielectric properties.

Data Sheet:

Silica fiber products:

A kind of inorganic high temperature resistance fiber with the content of SiO₂ higher than 95%, its soften temperature can nearly reach to 1700℃.It can be used in high temperature environment below 900℃ for a long time.

- Q: How does fiberglass fabric perform in cryogenic applications?

- Fiberglass fabric performs exceptionally well in cryogenic applications due to its unique properties. Cryogenic temperatures can significantly impact the performance of materials, but fiberglass fabric exhibits excellent thermal insulation and low thermal conductivity, making it ideal for use in cryogenic environments. One of the key advantages of fiberglass fabric in cryogenic applications is its ability to withstand extremely low temperatures without losing its structural integrity. It has a high melting point and can resist thermal stress, which ensures its durability and reliability even in harsh conditions. This makes fiberglass fabric suitable for use in cryogenic storage tanks, pipelines, and other equipment that handle liquefied gases such as nitrogen, oxygen, and LNG (Liquefied Natural Gas). Additionally, fiberglass fabric has low thermal expansion, meaning it does not contract or expand significantly when exposed to extreme temperature changes. This property is crucial in cryogenic applications as it helps prevent leaks or cracks that could compromise the integrity of the system. Furthermore, fiberglass fabric is non-corrosive and resistant to chemicals, making it suitable for use in cryogenic environments where exposure to potentially corrosive substances is common. It does not react with most cryogenic fluids, ensuring that the fabric remains intact and does not degrade over time. Another important factor is the excellent electrical insulation properties of fiberglass fabric. Cryogenic applications often involve the handling of electrical components, and using fiberglass fabric as an insulating material helps prevent electrical conductivity issues that could arise due to temperature fluctuations. Overall, fiberglass fabric performs exceptionally well in cryogenic applications due to its thermal insulation, low thermal conductivity, high melting point, low thermal expansion, chemical resistance, and electrical insulation properties. These characteristics make it a reliable and durable material for use in various cryogenic systems and equipment.

- Q: What are the different thickness options for fiberglass fabric?

- The different thickness options for fiberglass fabric typically range from 0.5 ounces per square yard (OSY) to 12 OSY, with intermediate options such as 1 OSY, 3 OSY, and 6 OSY available.

- Q: What are the different fiberglass fabric finishes for abrasion resistance?

- There are several different fiberglass fabric finishes that are specifically designed to enhance abrasion resistance. These finishes are applied to the fabric during the manufacturing process and serve to improve the fabric's durability and resistance to wear and tear. One commonly used fiberglass fabric finish for abrasion resistance is a silicone coating. This coating forms a protective layer on the fabric's surface, making it more resistant to abrasion and ensuring a longer lifespan. Silicone-coated fiberglass fabrics are often used in applications where high levels of abrasion are expected, such as conveyor belts and industrial curtains. Another popular finish for abrasion resistance is a PVC coating. This type of coating provides a strong barrier against friction and wear, making the fabric more resistant to tears, punctures, and other forms of damage. PVC-coated fiberglass fabrics are commonly used in applications such as protective clothing, tents, and covers for machinery and equipment. In addition to silicone and PVC coatings, there are also other finishes available for enhancing abrasion resistance in fiberglass fabrics. For example, some fabrics may be treated with a polyurethane coating, which provides similar benefits to silicone and PVC coatings. Other finishes may include chemical treatments or laminations that offer improved abrasion resistance. Ultimately, the choice of fiberglass fabric finish for abrasion resistance will depend on the specific application and the level of protection required. Manufacturers and users of fiberglass fabrics should carefully consider the intended use and the potential wear and tear that the fabric may encounter in order to select the most appropriate finish for their needs.

- Q: What is the tear strength of fiberglass fabric?

- The tear strength of fiberglass fabric can vary depending on the specific type and weave of the fabric. However, generally speaking, fiberglass fabric is known for its excellent tear strength, making it highly resistant to tearing or ripping under normal circumstances.

- Q: Is fiberglass fabric easy to cut and sew?

- Yes, fiberglass fabric is relatively easy to cut and sew. It can be cut using standard fabric scissors or a sharp utility knife. However, it is important to note that fiberglass fabric can be more difficult to cut than traditional fabric materials due to its strength and durability. It is recommended to use sharp tools and apply steady pressure to ensure clean cuts. When it comes to sewing, fiberglass fabric can be sewn using a regular sewing machine or by hand. It is recommended to use a heavy-duty needle and a strong, durable thread such as polyester or nylon. Additionally, it may be helpful to use a walking foot attachment on the sewing machine to handle the thickness and stiffness of the fabric. Overall, while fiberglass fabric may require slightly more effort and specialized tools compared to traditional fabrics, it is still possible to cut and sew it with relative ease. With proper tools, techniques, and precautions, you can successfully work with fiberglass fabric for various projects.

- Q: How is fiberglass fabric dyed or colored?

- Fiberglass fabric can be dyed or colored using various methods. One common approach is to immerse the fabric in a dye bath containing the desired colorant, such as a pigment or dye solution. The fabric is then heated to a specific temperature, allowing the dye molecules to penetrate and bond with the fibers. Another method is printing, where the desired pattern or design is applied to the fabric using specialized dyes or pigments. The fabric can also be colored during the manufacturing process by incorporating colored or pre-dyed fibers. Overall, the specific technique used to dye or color fiberglass fabric depends on the desired outcome and the capabilities of the manufacturer.

- Q: Can fiberglass fabric be used for making protective sleeves?

- Yes, fiberglass fabric can be used for making protective sleeves. Fiberglass fabric is known for its durability, heat resistance, and ability to withstand high temperatures. These properties make it an excellent choice for protective sleeves, especially in industries where workers are exposed to extreme heat or hazardous materials. Fiberglass fabric can provide a reliable barrier against heat, flames, chemicals, and abrasions, thus protecting the wearer's arms from potential injuries. Additionally, fiberglass fabric is lightweight and flexible, ensuring comfort and ease of movement for the wearer.

- Q: What are the characteristics of glass fiber acoustic panels?

- To effectively control and adjust the reverberation time, reduce noise, improve the sound absorbing ceiling. Glass fiber has the heat insulation performance is very good, for air-conditioned venues, can reduce the indoor temperature outside, so as to effectively save energy. The glass fiber acoustic ceiling almost does not absorb moisture from the air, moisture resistance is excellent, can flatness from size to stability in any humid environment.

- Q: How to distinguish the good and bad of aluminum foil glass fiber cloth? What is the plain glass fiber cloth, glass fiber cloth and twill satin glass cloth?

- Satin glass cloth. Is referred to as a variety of satin glass fiber cloth organization. Including all kinds of glass fiber cloth satin and sateen change organization, different specifications of different styles of fabric.

- Q: Can fiberglass fabric be used for making soundproofing materials?

- Yes, fiberglass fabric can be used for making soundproofing materials. Its dense and fibrous composition helps absorb sound waves, reducing noise transmission and enhancing sound insulation capabilities.

Send your message to us

High Temperature Resistance Silica Chopped Fiberglass Fabric Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords