high temperature resistance ceramic fiber special shaped part

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

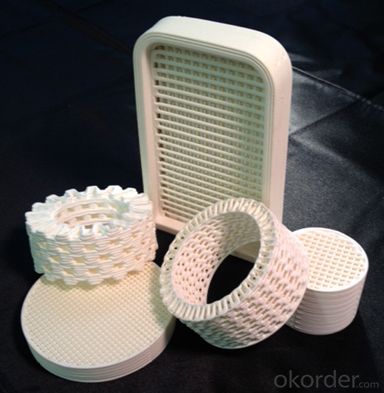

Product Image:

Product Description & Application:

The raw materials are the ceramic fiber cotton and a certain percentage of organic adhesive which mixed in water, by vacuum forming ways of processing into shaped refractory products.

Insulation for a variety of pipe;

Heat insulation for casting equipment and high temperature parts;

Sealing at a high temperature.

Product Capability:

High temperature resistant, low heat conduction rate;

High Thermal and chemical stability;

High mechanical strength, can be processed according to the needs of different shapes;

Easy to use.

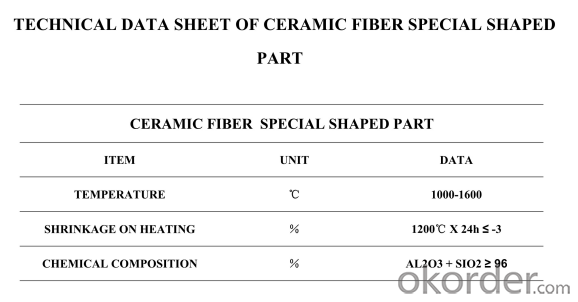

Data Sheet:

Ceramic Fiber Products:

Ceramic fiber products are excellent insulation materials with the advantages of low thermal conductivity,resistance from high temperature,good chemical stability and electrical insulation etc,with the working temperature ranging from 800-1500 degree Celsius.

Main products:ceramic fiber bulk,yarn,cloth,tape,rope,sleeve,blanket,paper,board,felt,special shaped part,module,high-temperature conveyer belt etc.They are widely used in metallurgy,petrochemical,shipbuilding,automobile,construction,power plant,machinery,furnace,etc.

- Q: Who can help me introduce the principle of vacuum forming of ceramic fiber board? Thank you very much.

- Product Description: with stable performance, long fiber and tensile strength, less slag ball, high thermal stability, white color and so on. The classification temperature is 1050-1600 degrees centigrade. It is the preferred material for the production of fiber textiles. It is also an ideal material for sealing, filling and heat insulation in high temperature environment. Features: low thermal conductivity, low thermal capacity, excellent chemical stability, corrosion resistance, excellent sound absorption property, excellent thermal stability. Typical applications: raw materials for industrial ceramic fiber wet products; raw materials for ceramic fiber unshaped products; high temperature kilns, heating devices, wall linings, gap filling materials, etc.. Two, ceramic fiber blanket Product Description: white color, regular size, set fire, heat insulation, insulation in one. Free from any binding agent. In the neutral and oxidizing atmosphere, the tensile strength, toughness and fiber structure can be maintained for long term use. The temperature is 950-1400 centigrade.

- Q: What is the process of producing ceramic fiber mats?

- 3) good high temperature strength and heat insulation performance (refer to physical and chemical indexes).4) having a higher level of electrical insulation and high temperature electrical insulation than glass fibers.5) non-toxic, harmless and odorless.

- Q: What is ceramic fiber?

- 1, ceramic fiber is a fibrous lightweight refractory material, has the advantages of light weight, high temperature resistance, good thermal stability, low thermal conductivity, specific heat and resistance to mechanical vibration, and thus in machinery, metallurgy, petroleum, ceramics, glass, electronics and other industries have been widely used.2, ceramic fiber products is a good refractory. The utility model has the advantages of light weight, high temperature resistance, small heat capacity, good insulation and heat insulation performance, good high-temperature heat insulation performance, no toxicity, etc..3, light quality, good heat insulation performance, good thermal stability, good chemical stability, easy processing and convenient construction. It is neither wear-resistant nor collision resistant, can not resist the erosion of high-speed airflow, and can not resist the erosion of molten slag.

- Q: What is ceramic fiber paper?

- The specification is various, the thickness of 0.5-10mm. products using four consecutive rinsing and slag removal process, the fiber distribution, high tensile strength good flexibility, no delamination, no slag, can be cut with a little organic matter.

- Q: What ceramic fiber profiled products are needed in steel mills? What's the name?

- Ceramic fiber and nano heat insulation board are used for heat insulation, and in the steel plant are generally used for ladle, tundish insulation, and now can also be made of nano insulation products special-shaped products.

- Q: What kind of material is ceramic fiber? What are the basic performance?

- (2) the density of Tao Xianzhan is below 200Kg/m3 (generally 160kg / m3), only light heat resistant lining L / 6 - 1/7.(3) the heat capacity is only 1 / 9 of light heat resistant lining and light fireclay bricks.(4) the ceramic fiber is stable in high temperature, the residual shrinkage rate is very small, and it needs no shrinkage or expansion joints, so it is easy to construct.(5) the coefficient of thermal conductivity is small. On the hot surface temperature of 600 degrees Celsius (the average temperature of 366 DEG C) when the orientation coefficient is 0.078W / (M. K); 900 (the average temperature is 551 DEG C) of O.096W / (m.k); 1100 (the average temperature is 678 DEG C) of 0.125W / (m.k), is about light fireclay bricks 1 / 8, for the light at 1 / 10 heat resistant lining.(6) sound insulation effect is good. The ceramic fiber coating can reduce the high-frequency noise with frequency less than 1000Hz, and also absorb some low-frequency noise.(7) it has a certain tensile strength.(8) good chemical stability.(9) good elasticity (78% at normal temperature), easy to transport and install.(10) it has better resistance to airflow erosion, and can withstand 30 - 50m/s airflow erosion.

- Q: Refractory ceramics and other refractory materials manufacturing is a big industry?

- Also belong to the building materials industry, glass industry and other industries, are Rong Sheng refractories industry ah.

- Q: What brand of ceramic fiber products is best?

- The quality of the above products can be highlighted from two aspects:1, large-scale production2, the application of advanced technology3, brand awareness of the high and low

- Q: What is the use of ceramic fiber paper?

- Mifso-14 ceramic fiber paper gasket is Xin Xing sealing material factory is composed of ceramic fiber products through precise cutting, punching, die stamping process (part of the product after ultra high pressure adhesive bonding) produced. Can be customized by users to produce sizes.

- Q: ceramic fiber

- Advantages of ceramic fiberRefractory ceramic fiber material is a lightweight and efficient thermal insulation material. It has the following advantages over traditional heat insulation materials:Ceramic fiber as lining, low volume density: ceramic fiber lining than light heat insulation brick lining light more than 75%, lighter than light castable lining light 90% to 95%. If using fiber lining, it can greatly reduce the steel structure load and prolong the service life of the furnace.The heat capacity (heat storage capacity) of ceramic fiber lining is low: the heat capacity of ceramic fiber is only about l/10 of light heat resistant lining and light castable lining, and the heat capacity of lining material is proportional to the weight of lining. Low heat capacity means the furnace in the reciprocating operation absorb less heat and heating speed, greatly reducing the operational control of the temperature in energy consumption, especially for heating furnace and furnace, furnace shutdown has obvious energy saving effect.Ceramic fiber lining: low thermal conductivity of ceramic fiber lining in the average temperature of 400 degrees, the thermal conductivity is less than 0.1w/mk, the average 600 degrees less than 0.l5 w/mk, average 1000 degrees less than 0.25w/mk, about l/8 as a lightweight clay brick, lightweight refractory lining l/10, adiabatic effect.The construction of ceramic fiber lining is simple: no expansion joints are needed during construction, and the construction personnel can be started after the basic training. The technical factors of construction have little influence on the insulation effect of the lining. Ji'nan Sheng Yang

Send your message to us

high temperature resistance ceramic fiber special shaped part

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords