High Tensile Strength Ceramic Fiber Module

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 kg

- Supply Capability:

- 2000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceramic fiber module is made by processing the corresponding ceramic fiber needling blanket with the specific machine according to structure and size of the fiber module. During the process, it should maintain a certain percentage of compression, so as to ensure the fiber modules can swell to different directions and can crush together into a whole without crack after the lining construction. The ceramic fiber modules can be fixed on the steel plate of industrial furnace by different kinds of anchors.

Product Applications:

Ceramic Fiber Module are ideal for use in the below applications

Petrochemical furnaces, cracking furnaces .

Steel industry furnace, annealing furnace, roller hearth furnace, etc.

The aluminum industry are hot furnace, furnace are Ceramic industry tunnel kilns, intermittent kilns.

Waste recycling, combustion chamber.

High-end household appliances insulation device.

Product Advantages:

Excellent chemical stability

Excellent thermal stability

Excellent flexibility, the module is in pre-compression state, after the lining masonry

The Expansion of modules enable seamless lining,fiber lining can be compensated to improve

Insulation performance of Fiber lining, and the overall performance is good

Main Product Features:

Low thermal conductivity, low thermal capacity

Excellent thermal stability and good resistance to heat shock

Excellent tensile strength

Good anti-stripping performance

Good Sound-absorbing performance

Non-brittleness material, good flexibility

Excellent machining performance

Resistance to wind and erosion, long service life

Excellent heat insulation, fire prevention, sound absorption performance

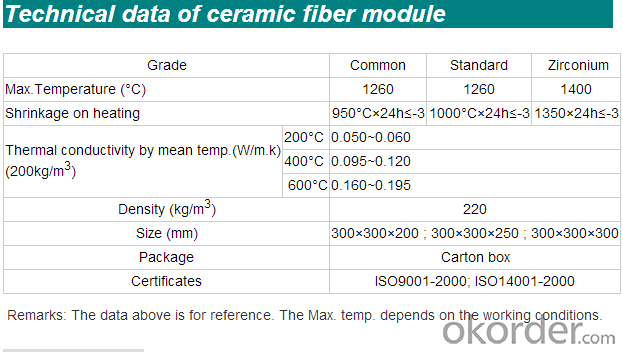

Product Specifications:

FAQ:

Q1.What is your MOQ?

A1 :MOQ may vary by customer's special requirement; we try our best to meet your business requirement.

Q2.Can you provide sample?

A2: Yes, we can offer sample , and some samples are free

Q3:Can you delivery by express?

A3: Yes, we can delivery by any express

Product Picture

- Q: Can ceramic fibers be spun? Hope experts answer, if you are the one!

- It should be spun from cotton, spun into spun yarn, and then joined with wire or glass fiber, and then twisted into threads to make cloth or rope

- Q: Ceramic fiber plate and aluminium silicate plate are chosen as lining materials

- Ceramic fiber surface roughness, accurate size, good toughness, can be arbitrarily cut, good insulation effect; ceramic fiber board can be distinguished according to the temperature, heat is widely used in the back lining of industrial furnace and kiln temperature, kiln is an important guarantee for energy saving, high yield and quality factors of A.

- Q: Ceramic fiber module or refractory brick for hot galvanizing furnace body insulation? Who gave me an analysis?

- The arrangement mode of the ceramic fiber module adopts "soldier row type" - along the module compression size. Fiber module arrangement using ceramic fiber blanket folded thickness after 20mm compression, and the use of "U" type nail to keep the 500~700mm distance to the fiber module fixed to insert compensation fiber expansion surface may produce contraction, the structure can avoid the "parquet" arrangement, fiber module for the corner site the expansion caused by uneven phenomenon, "playboy" has the best effect of adiabatic. When the back lining of the furnace top is installed, the quick card matching module is used for temporary fixing with bolts.

- Q: How to install refractory fiber?

- Dry plate is used to spray adhesive mechanical pressing low density has good elasticity and flexibility is usually used for wet insulation sealing by washing vacuum shaping mould plate of high density, hardness, mechanical processing can be generally used as fireproof heat insulation is very good Oh, you can try

- Q: What about the composite reflecting insulation board and ceramic fiber?

- The maximum temperature of ceramic fiber heat insulation material can be up to 1400 degrees. Although the highest use temperature of ceramic fiber is higher than that of Tianjin solid composite reflecting insulation board, the heat insulation effect is far worse.

- Q: What is the refractory temperature of the ceramic fiber cloth?

- Non-toxic, harmless, no adverse effects on the environment; the scope of application of ceramic fiber cloth: all kinds of high temperature furnace, thermal insulation pipes and containers; door, valve, flange sealing, fire door, fire shutter door curtain, high temperature sensitive materials; engine and instrument cable insulation, fireproof coating material, fireproof material; thermal insulation cover with cloth, high temperature expansion joint filler, flue lining; high temperature resistant safety products, fire service, high temperature filtration, sound and other fields instead of asbestos

Send your message to us

High Tensile Strength Ceramic Fiber Module

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 kg

- Supply Capability:

- 2000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords