High Technology Top Sale DI Pipe Fittings

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Product Name: | Di Pipe Fittings |

| Certificate: | ISO9001:2008,TS16949,PED97/23 |

| Material: | Stainless Steel, Carbon Steel, Steel Alloys, Aluminum, Brass, Bronze, etc. |

| Specification: | Size:1/4"~30" THK: SCH 5S~SCH XXS |

| Standard: | ASME/ANSI B16.9, MSS-SP-43, MSS-SP-75, EN/ DIN2605,JIS B2311/2312/2313 |

| Name: | Elbow, Bend,Tee, Cross, Reducer, Cap, Union, Boss, Swage, Sockolet, etc. |

| Quality Control | 100% Inspection On Critical Dimesions Before Shipped |

| Packing: | Carton and pallet |

| According to your requirment | |

| Transaction: | T/T |

| Payment Term: | FOB,CIF,CFR |

| Delivery time: | 20-30 workdays |

| Production capacity: | 100t/month |

High Technology Top Sale DI Pipe Fittings

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.

CNBM International is highly recognized by its business partners and clients all over the world and has obtained rapid development under the spirit of win-win. We will carry on the mutual beneficial, innovative and revolutionary trading structure as we did before, create value for our employees, share holders and clients and benefit the whole society in our future development.

- Q: How is steel wire rope used in elevators?

- Steel wire rope is used in elevators as the primary means of supporting and moving the elevator car. It is an essential component of the elevator system, providing strength and stability. The wire rope is attached to the elevator car and loops over a traction sheave, which is connected to an electric motor. As the motor rotates the sheave, the wire rope moves, lifting or lowering the elevator car. The steel wire rope's high tensile strength and durability make it ideal for withstanding the heavy loads and constant use in elevator applications.

- Q: How is steel used in the construction of warehouses and storage facilities?

- Steel is commonly used in the construction of warehouses and storage facilities due to its strength and durability. It is used for the framework and support structures, as well as for roofing and siding. Steel provides a secure and reliable structure that can withstand heavy loads and harsh weather conditions, making it ideal for these types of buildings.

- Q: How is steel rebar used in concrete construction?

- Steel rebar is used in concrete construction to provide reinforcement and strength to the concrete structures. It is typically placed within the concrete forms before pouring, creating a framework that helps to increase the structural integrity and durability of the concrete. The steel rebar acts as a tension device, absorbing and distributing the forces that act upon the concrete, such as those caused by weight, temperature changes, and natural disasters. This reinforcement helps to prevent cracking, increase load-bearing capacity, and enhance the overall performance and lifespan of the concrete construction.

- Q: What are the different types of steel wires and their applications in telecommunications?

- There are several types of steel wires commonly used in telecommunications. These include galvanized steel wires, stainless steel wires, and high-tensile steel wires. Galvanized steel wires are coated with a layer of zinc, which provides corrosion resistance and durability. They are commonly used for overhead transmission lines, telephone cables, and fiber optic cables. Stainless steel wires are highly resistant to corrosion and have excellent strength properties. They are often used in marine environments, underground installations, and for aerial cables where high tensile strength is required. High-tensile steel wires are known for their exceptional strength and toughness. They are used in applications where heavy loads and long spans are involved, such as suspension cables for bridges and power transmission lines. Overall, these different types of steel wires play a crucial role in the telecommunications industry by providing strength, durability, and reliability for transmitting signals and supporting communication infrastructure.

- Q: How is steel pipe coated for corrosion resistance?

- Steel pipe can be coated for corrosion resistance through various methods such as galvanization, epoxy coating, or fusion-bonded epoxy coating. Galvanization involves applying a layer of zinc to the steel surface, forming a protective barrier against corrosion. Epoxy coating involves applying a layer of epoxy resin to the pipe surface, providing a durable barrier against corrosion. Fusion-bonded epoxy coating involves applying a powder coating to the heated pipe surface, which then melts and fuses to form a corrosion-resistant layer. These coating methods help protect steel pipes from the damaging effects of corrosion, extending their lifespan and maintaining their structural integrity.

- Q: What are the applications of steel in the marine industry?

- Steel is widely used in the marine industry due to its exceptional strength, durability, and corrosion resistance properties. It is employed in the construction of ship hulls, decks, and superstructures, providing structural integrity and ensuring the vessel's longevity in harsh marine environments. Additionally, steel is utilized in the fabrication of marine equipment, such as propellers, shafts, and rudders, contributing to efficient propulsion systems and smooth navigation. Its applications in the marine industry are crucial for ensuring the safety, reliability, and performance of various maritime vessels and structures.

- Q: What are the common types of steel products used in the railway industry?

- The common types of steel products used in the railway industry include rails, wheels, axles, and various structural components such as beams and plates. These steel products are specifically designed to withstand the heavy loads, high speeds, and constant vibrations associated with railway operations.

- Q: What are the different types of steel chains and their uses in the automotive manufacturing process?

- There are several types of steel chains used in the automotive manufacturing process. One common type is roller chains, which are used in the engine to transmit power from the crankshaft to the camshaft, ensuring proper valve timing. Another type is timing chains, which are responsible for synchronizing the rotation of the crankshaft and camshaft to maintain engine performance. Additionally, conveyor chains are used in assembly lines to transport car components during the manufacturing process. These steel chains are crucial in ensuring the efficiency, reliability, and precision of automotive production.

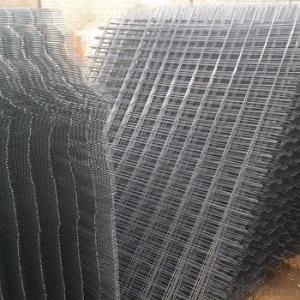

- Q: What are the different types of steel meshes and their uses?

- There are several different types of steel meshes, each with their own specific uses. Some common types include welded wire mesh, expanded metal mesh, and woven wire mesh. Welded wire mesh is made by welding intersecting wires together, and it is commonly used in construction, fencing, and agriculture. Expanded metal mesh is created by cutting and stretching a sheet of metal, resulting in a diamond-shaped pattern. It is often utilized for grating, walkways, and security applications. Woven wire mesh is made by weaving individual wires together in a crisscross pattern, and it finds application in filters, screens, and decorative purposes. These are just a few examples, but steel meshes are versatile and can be tailored to meet various needs across industries.

- Q: What is the process of steel casting?

- The process of steel casting involves melting steel in a furnace, pouring the molten metal into a mold, and allowing it to cool and solidify into the desired shape. The mold is usually made of sand or ceramic materials, which are carefully prepared and shaped to create the desired design. Once the steel has solidified, the mold is removed, and the casting is cleaned and finished to meet the required specifications.

Send your message to us

High Technology Top Sale DI Pipe Fittings

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords