High Speed Beer Filling and Sealing Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Beer Can Filling and Sealing Machine

This production line is suitable for the production of all kinds of carbonated drinks contained in aluminum 2-piece pop-top can, such as cola, aerated water, ice tea, etc, It is an ideal machine for small-and medium-sized beverage factories.

Descriptions:

1. This filling machine is used for filling carbonated beverage in cans , such as beer, cola, energy drinks and soda water.

2. This beverage can filling machine can be used for different material of cans, such as plastic, iron, aluminum and so on ,and the different size of cans is allowed.We can design the euipment according to your requirements

3. This beverage can filling machine is applicable for equal pressure filler and capper of carbonated drinks in beer and drink industry.

4. The can filling machine is a pop canned beer in the digestion and absorption of advanced foreign and domestic sealing machine on the basis of independent development of the can filling, sealing unit.

5. Filling and sealing is the overall designed, power system by filling sealing system to Ensure that both the absolute synchronization and coordination.

6. Beverage can filling machine adopts the advanced machine, electrical equipment, and Pneumatic control technology.

7. The beverage can filling machine has the characteristics of filling reposefully, high speed, liquid level control, capping reliably, frequency conversion timing, less material loss.

Rotary type 2 in 1

| Model | Unit | GDF12-1 | GDF18-6 | GDF24-6 |

| Capacity | Cans/h | 2000 | 5000 | 8000 |

| Power | KW | 0.75 | 3.7 | 3.7 |

| Dimension | mm | 1750*1140*1950 | 2320*1400*1900 | 2580*1675*1900 |

| Weight | KG | 1800 | 2500 | 3000 |

Linear type:

| Model | Unit | CGJ-50 | DGC-12/16 | YLG-40 |

| Capacity | Cans/h | 3000 | 1500-3500 | 2400 |

| Power | KW | 0.55 | 0.75 | 0.75 |

| Dimension | mm | 1900*530*1100 | 810*1050*2050 | 930*700&1850 |

| Weight | KG | 480 | 500 | 500 |

| Suitable can size | mm | Φ40-80 | Φ40-90, H 50-340 | Φ50-67, H 90-200 |

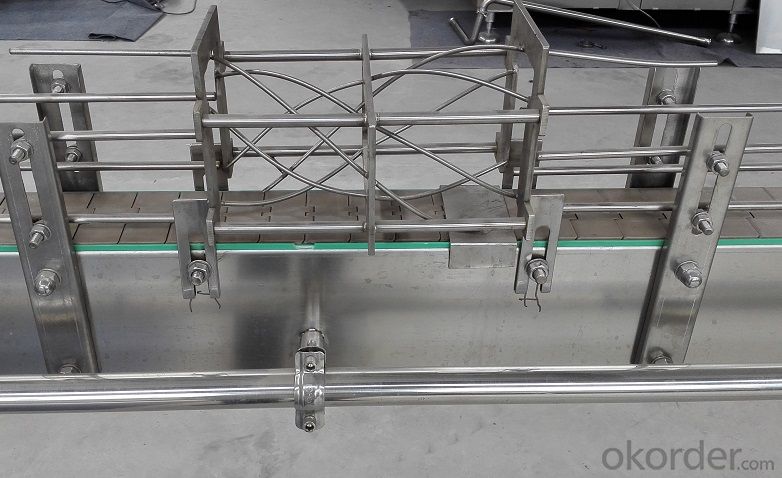

Rotary Type 2 in 1 Machine:

Can Rinser:

Can filling head:

can sealing head:

can inverter:

Linear Type Can Filling Production Line:

Installation, debug, training, after sales

(One.)Installation, debug

After equipments reached the workshop of customer, place the equipments

according to plane layout we offered. We will arrange seasoned technician for

equipments installation, debug and test production at the same time make the

equipments reach the rated producing capacity of the line. Time for installation and debug is 15-25 days.

(Two.)Training

Our company offer technology training to customer. The content of training is

structure and maintenance of equipments, control and operation of equipments.

Training is in the workshop of customer. Seasoned technician will guide and

establish training outline. After training, the technician of buyer could master the

operation and maintenance, could adjust the process and treat different failures.

(Three.) Quality guarantee

We promise that our goods are all new and not used. They're made of suitable

material, adopt new design. The quality, specification and function all meet the

demand of contract. We promise that the products of this line could storage for one

year without adding any aseptic.

(Four.)After sales

1,After checking, we offer 12 months as quality guarantee, free offer wearing parts

and offer other parts at the lowest price. In quality guarantee, the technician of buyers

should operate and maintain the equipments according to seller's demand, debug

some failures. If you could not solve the problems, we will guide you by phone; if the

problems are still can not solve, we will arrange technician to your factory solving the

problems. The salary is 80usd per day.

2,After quality guarantee, we offer technology support and after sales service.

Offer wearing parts and other spare parts at favorable price; after quality guarantee,

the technician of buyers should operate and maintain the equipments according to seller's

demand, debug some failures. If you could not solve the problems, we will guide you by

phone; if the problems are still can not solve, we will arrange technician to your factory

solving the problems. The salary is 80usd per day.

Check & accept of equipments

One. check & accept standard(bottles and caps should be eligible)

(1)Woring efficiency of the whole line ≥85%;

(2) The quantity of waster of the whole line <=0.2%

1) Bottle leakage: invert the bottle and press by hand come forth water leakage

2) Without cap, crooked cap or cap with damage

3) Clip bottle bad or damage the bottle seriously

(3).The whole line will run continuously for 8 hours, stable quantity of the average

acceptable-end products>=99%

(4).The distance between the material inside the bottle and the top of bottle neck is less

than 8mm (full after cooling)

(5).The liquid reflux<10%

(6).The sanitation of the product meets the standard of beverage industry.

(7).About the checking and accepting of animalcule will carry sample and check according to the standard of nation beverage industry, the result of checking will according to the request of industry standard.

Two. Check & accept procedure

(1) After debugging the machine in seller's factory, after checking out and signature of two sides, then we can shipping the machine.

(2) Finish installation and debugging the machine, after checking out, Running the whole production line to show the line function, after certification then final checking. Meanwhile training for operation, maintenance and so on, then make a signature of two sides to become effective.

- Q: What is the general packing cost of beer beverage packaging?

- Beer beverage hot shrink packaging generally use PE heat shrinkable film, packaging temperature is usually in accordance with the film material and thickness to set,

- Q: A & B two sets of packaging machines, at the same time packaging quality of 500 kilograms of goods

- (3) large variance, indicating that this group of data volatility, variance is small, volatility is relatively stableAnswer: (1) a = x (501+500+503+506+504+506+500+498+497+495), 10=501,B = x (503+504+502+498+499+501+505+497+502+499), 10=501;(2) S2, =1/n[(501-501) 2+ (500-501) 2+... + (495-501) 2]=12.6,S2 B, =1/n[(503-501) 2+ (504-501) 2+... + (499-501) 2]=6.4;(3) a b > S2 dreams S2,The quality of R B packaging machine 10 bags of sweets is relatively stable.Comments on the subject, mainly on the average number, variance calculation, and their significance, the correct memory formula is the key to solving problems

- Q: What kind of reducer is commonly used in packaging machinery?

- There are many kinds of reducers used. What kind of machines are they under?

- Q: What machine does the packing carton machine have?

- Since its establishment, the company has continued to provide specialized packaging equipment and transportation equipment for domestic first-class enterprises, as well as perfect solutions for automated transportation systems.

- Q: How much is the tableware wrapping machine?What's the price of the tableware wrapping machine?

- Tableware packaging machine machine standard price of about 38000, excluding tax, tableware packaging machine is designed for tableware (e.g., chopsticks, bowls, dishes and so on) a modern packaging machinery packaging, this machine is mainly composed of conveyor, packaging machine, output machine, shrink machine, composed of four parts.

- Q: What are the structures of the packaging machinery?

- Is a company engaged in outsourcing clients, packaging, processing, packaging equipment, leasing, services, sales in one of the specialized companiesSales of second-hand packing equipment according to the customer's product features and requirements. Reduce customer purchasing costsAccording to the customer's product characteristics and requirements. Select the best packaging equipment for customers, reduce customer purchasing costsPackaging equipment spare parts sales and maintenance services

- Q: What are the packaging machines that use temperature control watches?

- Such as shrink machine, vertical packaging machine, pillow type packaging machine, continuous sealing machine,

- Q: What is a packaging machine?

- Packaging machinery refers to the machinery that can complete all or part of the product and commodity packaging process. The packaging process includes filling, wrapping, sealing and other main processes

- Q: Food, equipment, tools, containers, packaging materials, etc. shall comply with food safety standards or requirements

- 5009.101 determination of antimony in polyester resins and their moulding products for food containers and packaging materialsGB 13113 hygienic standard for polyethylene terephthalate moulding articles for food containers and packaging materials

- Q: Donkey hide gelatin cake made of sticky, forming very well, that is, vacuum packaging, after a little sticky in the vacuum bag, what's going on?

- Personal advice:In this respect, I suggest you look for the factory in Dongguan, Tangxia, which is the base of vacuum bag production. By logistics or express delivery, the goods will be delivered soon!!

Send your message to us

High Speed Beer Filling and Sealing Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords