Cantilever winding machine made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Cantilever winding machine made in China

Description of Cantilever winding machine made in China

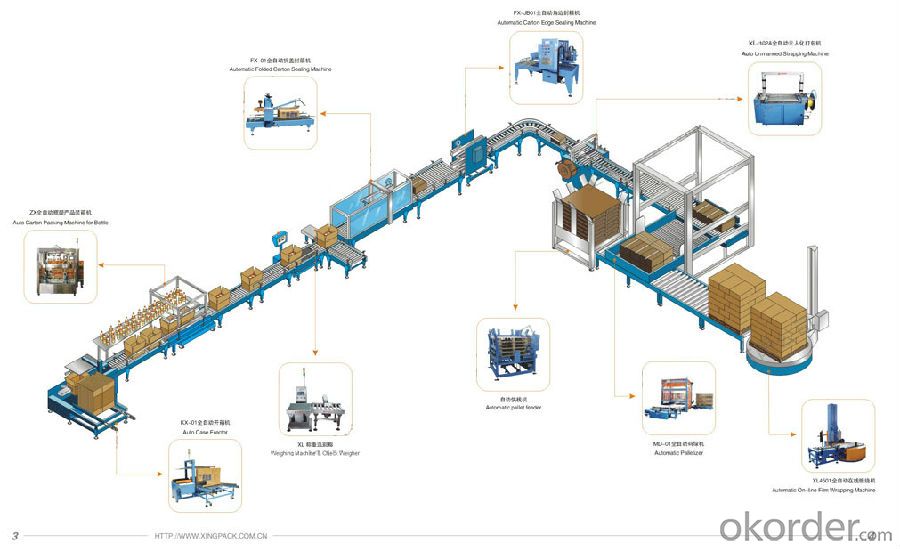

The cantilever type winding and wrapping machine is mainly applied to the overall wrapping of lighter or heavier goods in the food, beverage, chemical, papermaking, building materials and other industries. Its packaging cost is low and its efficiency is high. The installation method of the machine is flexible and can be installed on the wall, or it can be fixed by the bracket. At the same time, according to your actual requirements, you can use stand-alone or online equipment to achieve automatic packaging and automatic delivery of goods.

Packaging machinery refers to machinery that can complete all or part of the product and product packaging process. The packaging process includes major processes such as filling, wrapping, and sealing, as well as related processes such as cleaning, stacking, and disassembling.

In addition, packaging also includes processes such as metering or stamping on packages. The use of mechanical packaging products can increase productivity, reduce labor intensity, adapt to the needs of large-scale production, and meet the requirements of cleanliness and hygiene.

Main Features of Cantilever winding machine made in China

Membrane system: pre-stretched film frame, pre-stretch up to 250%, automatic film feeding, adjustable film feeding speed

Lifting column: chain structure, adjustable frequency of lifting speed

Control system: PLC programmable control, push-button operation panel, simple and clear

Operation function: automatic operation, automatic machine setting function

Cantilever performance: high-sensitivity emergency braking system, automatic cantilever reset

Automatic film breaking device: automatic clamping, cutting off the stretch film and achieving unattended operation

Conveyor system: conveyor line height: 400mm, conveyor line speed: 15m/min, conveyor line load: 1500kg

Safety protection: eye-catching flash safety warning and protective net (optional), photoelectric protection of incoming and outgoing goods (conveyor line)

Equipment composition: cantilever winding packaging machine + square gantry bracket +4m power transmission line + automatic on-off film

Specifications of Cantilever winding machine made in China

| Wrapping specifications | L500-1300mm*W500-1200mm*H300mm-1800mm |

| Packaging height | Customized according to customer requirements |

| Packaging efficiency | 20-30 pieces/hour 0-14 turns/minute |

| Membrane system | Pre-stretched film holder |

| Lifting column | Double chain structure, |

| Power/voltage | 1.9KW/AC220V |

| Packaging Materials | LLDPE stretch film, thickness 17-35um, width 500mm paper core: 3 inches |

| Dimensions | L3760*W2000*H3220mm with four pillars |

Applications of Cantilever winding machine made in China

Applicable to chemical fiber, tobacco, pharmaceuticals, publishing, refrigeration, home appliances, ceramics, beverages, hardware, chemicals, cans and other industries.

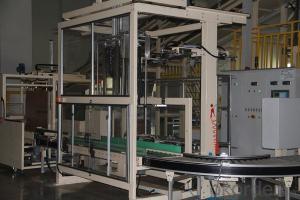

Images of Cantilever winding machine made in China

FAQ

Q1. Does your machine fit for different volumes?

A: Yes, one machine can fill different volumes, which is based on your product information.

Q2. Can your machine reach different production?

A: Yeah, we can make machines with different of filling nozzles, and the nozzle numbers based on your production. You can adjust different filling speed within the range.

- Q: Vacuum packing machine for cooked food: can whole chicken, whole goose and whole duck be packed?

- Buddy, you go to Taobao to buy a few hundred vacuum packaging machine, the 3 days is no problem, I suggest you go to buy a good brand, this thing hundreds of, garbage is easy to bad, shelf life 3 days, basically no problem

- Q: Bread packing machine Product features

- 4., high sensitivity photoelectric eye mark tracking, digital input seal cutting position, so that the seal cutting position more accurate.5. temperature independent PID control, better for all kinds of packaging materials.6. 、 positioning stop function, no sticking knife, no waste of coating.7. drive system is simple, more reliable work, more convenient maintenance.8. all control is realized by software, which is convenient for function adjustment and technical upgrading, and never falls behind.

- Q: What are the main plastic forming processes?

- 3. cold pressing molding. Cold pressing molding is also called cold pressing sintering molding. The difference between the cold press molding and the ordinary compression molding is that the material is pressurized and molded at room temperature. The mold after release can be heated or cured by chemical action. This method is used in the forming of polytetrafluoroethylene and some high temperature resistant plastics (such as polyimide, etc.). The general process is three steps of billet sintering cooling.4. transfer molding. Transfer molding is a molding process for thermosetting plastics. When molding, the mold is heated and softened in the heating chamber and then pressed into the mold cavity where it has been heated. According to the different types of transfer molding equipment form: trap type; the tank; the piston.The requirement of plastic molding for transfer molding is that the plastic should have a greater fluidity before reaching the curing temperature, and the curing rate must be faster at the curing temperature. Phenol, melamine, formaldehyde and epoxy resins can meet this requirement.Transfer molding has the following advantages: less waste edge products, can reduce the processing quantity; second molding with fine or brittle insert and perforation of the products, and can keep the insert and the hole position is correct; the product performance is uniform, accurate size, high quality; the mould wear small. The disadvantage is that the manufacturing cost is high compression mold die; the plastic loss; the fiber reinforced plastics for fiber orientation and anisotropy; and around the insert around the plastic, sometimes due to melting is not strong and make the products according to the strength reduction.

- Q: What are the packing machines?

- Glass glue category of automatic and manual soft packing machine, chemical, I do not know what you are talking about? You can go and have a look.

- Q: What are the main functions of packaging machinery and equipment?

- Packaging machinery can be realized in the packaging process, including filling and wrapping,

- Q: Color code positioning of packaging machinery

- The main products are: packaging machinery series of quantitative packing machine, vacuum packaging machine, packing machine, strapping machine, sealing machine, bag machine, carton forming machine, packing machine, winding machine, labeling machine, stacking machine, and the design of various transmission lines; at the same time, the production and sale of packing tape, stretch film and other packaging material.

- Q: The role of packaging equipment in packaging equipment

- Packaging is the necessary condition for products to enter the circulation field, and the main means of packaging is the use of packaging machinery. With the development of the times and the progress of technology, packaging equipment is playing a more and more important role in the field of packaging. The main functions of packaging equipment are as follows:

- Q: How is the production and characteristics of ceramic wall tiles different from the size and performance of molding?

- What is the production process of ceramic wall and floor tiles? What are the characteristics of the powders produced by spray drying?The tiles and other ceramic raw materials is similar to inorganic non-metallic materials (mainly silicate) as the main raw material, through accurate mixing processing, according to certain technology and shape the final firing. Significant features of the product shape are the rule of Fu Banzhuang, and most of the semi dry pressing method, and therefore suitable for automatic production line of raw materials 4 ingredients of crude, water, 4 fine granulation molding - burning glaze, glaze firing and assembly of I (paving) pick - packagingThere are different granulation methods in different production processes. The former is to dehydrate the mud and then dip it into the mud or directly with mud cake. The equipment has small investment, easy installation, operation and maintenance, irregular particle shape, uneven thickness and poor flowability. The I drying tower of the spray drying machine directly prepared the slurry into powder, which has high powder making efficiency and good powder flowability, and is the most ideal automatic powder powder making system at present. When the powder made from spray drying tower is pressed to wall and floor tile, the billet handle can be increased by about 30%.

- Q: How does the pulp solidify? What additives do you need? Curing agents? Or what do you need as binders?

- Urea formaldehyde resin is a water-soluble resin, easily cured, the cured resin colorless, non-toxic, good light resistance, long-term use does not change color, heat molding will not change color, can add various colorants to prepare various brightly colored products.Urea formaldehyde resin is hard, scratch resistant, weak acid, weak base and grease. It is cheap and has certain toughness, but it is easy to absorb water, so it has poor water resistance and electrical properties, and its heat resistance is not highThe use of urea formaldehyde resin is widely used in plastic, mold, laminated plastic, foam, also can be used for the production of water-soluble adhesive, the adhesive for wood; fabric shrinkproof and crepe treatment agent; used as a varnish of paper, in order to improve the wet strength of paper. The following is a simple Shaoxing on it the application of the plastic.

- Q: What are the packaging machines that use temperature control watches?

- Such as shrink machine, vertical packaging machine, pillow type packaging machine, continuous sealing machine,

Send your message to us

Cantilever winding machine made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords