Calcium Silicate Board Better than Gypsum

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Calcium Silicate Board Better than Gypsum

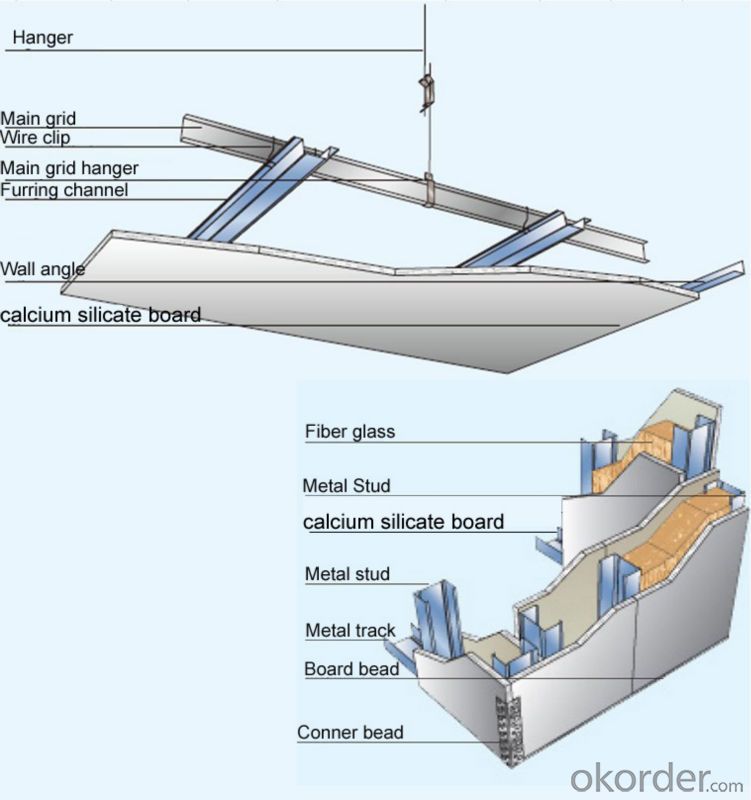

Asbestos-free Boards Calcium Silicate also known as the porous calcium silicate board, is a fiber-reinforced calcium silicate board, with silicon oxide, calcium oxide, and the reinforcing fibers as the main raw materials, made through mixing, heating, gelling, molding, autoclaving and drying processes. Calcium silicate board is a new type of rigid insulation material.

The calcium silicate board products, also called asbestos free mipor calcium silicate products, are mainly used in industries like power, oil, chemical, shipping, metallurgy, light to provide thermal insulation on industrial pipelines and thermal equipment to decrease heat loss, lower cooling effect on medium and delay its condensation during production, meanwhile save energy, improve work efficiency, lower the temperature at work area, improve working condition, avoid scald among workers.

The calcium silicate board can be specifically used as thermal insulation layer of power plant boiler and turbine body, chemical plant cracking furnace and distillation column, steel plant heating furnace, drying oven, paper mill digesting kettle, also the thermal cover on the pipelines in these plants.

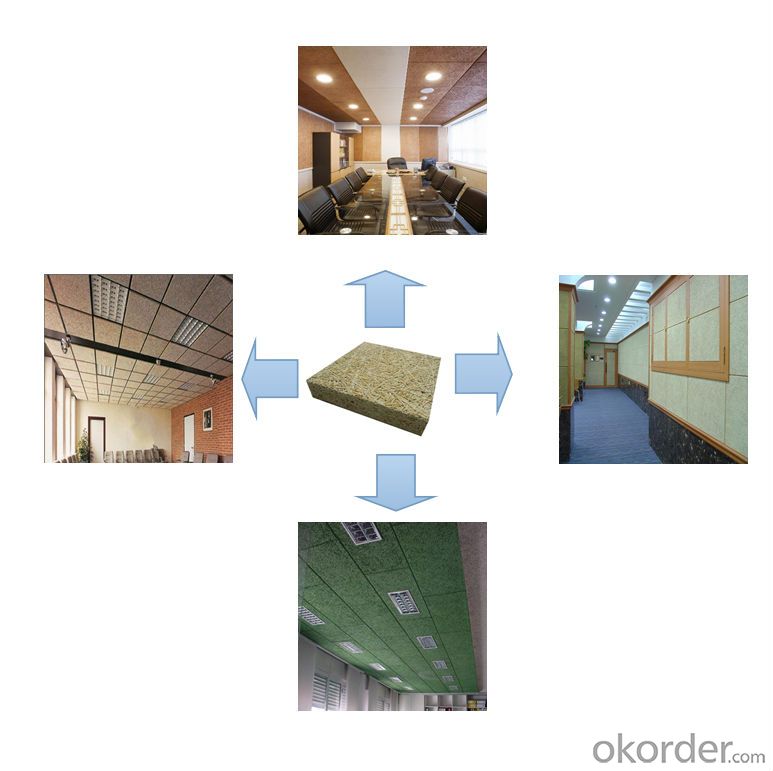

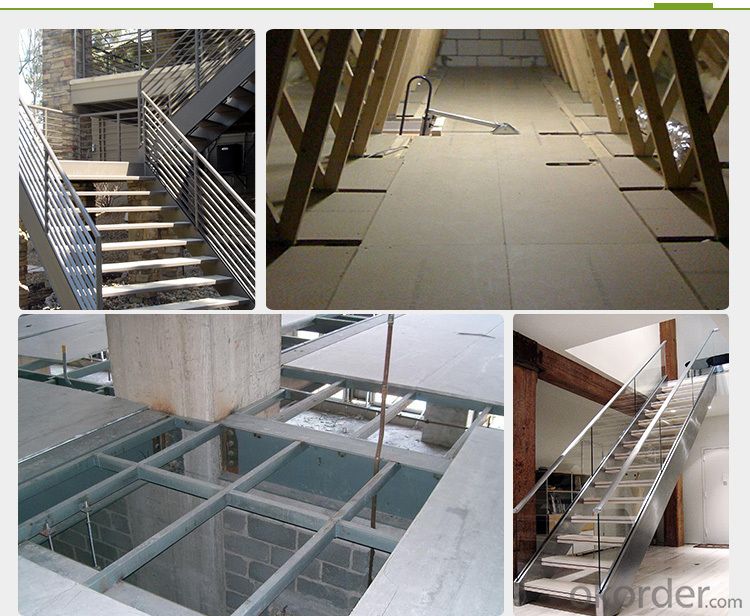

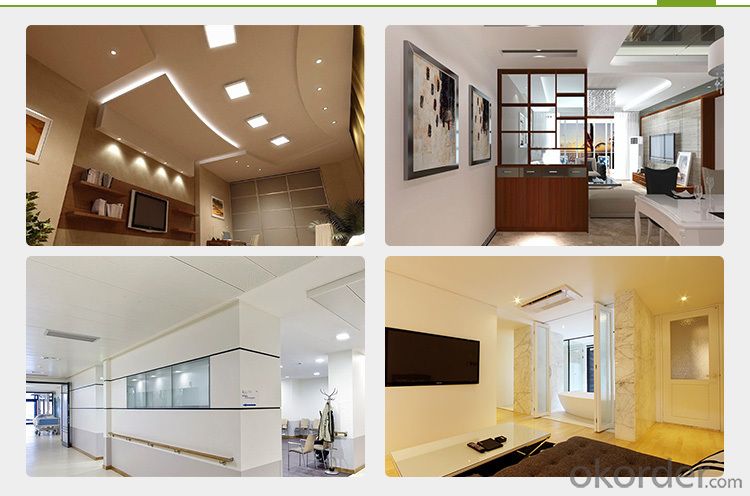

Product Applications:

Calcium Silicate Board are ideal for use in the below applications

Supermarket, marketplace

Underground, air port, bus station

Hall, corridor and toilet

Hotel, restaurant, kitchen

School, office, meeting room ,hospital etc

Product Advantages:

Good durability and can withstand high-temperature limit of the continuous thermal load

Low thermal conductivity,in the whole scope of use is unmatched within the adiabatic Performance

Light weight,high stength,its strength is rigid insulation products in the highest

Durability,long-term use of ceramic fiber felt no similar powder

Construction practical,with ordinary tools can be arbitrarily cutting products

Used safety,hygiene,asbestos-free,sulfur,chlorine such poisonous substances

Main Product Features:

Great soft bulk with elastic.

High strength

The strongest refractory materials among the inorganic thermal materials with similar density

Heat resistance:

Non-deformation within the working temperature range

Thermal insulation:

Lower thermal conductivity compared with other massive hard refractory materials

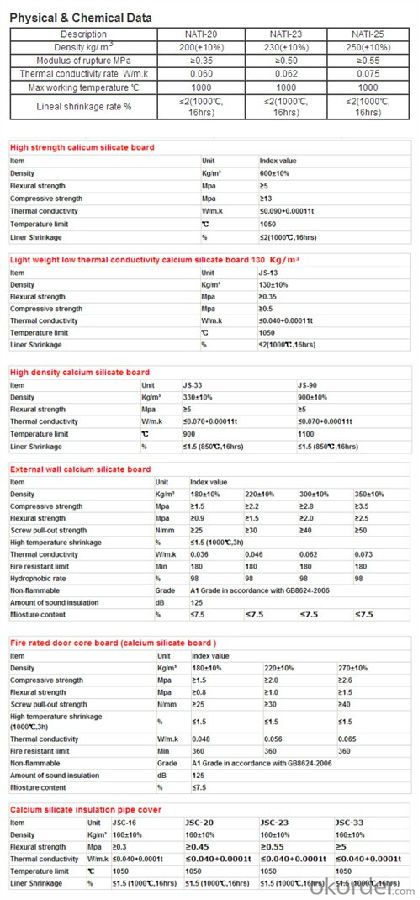

Product Specifications:

FAQ:

Q1.What is your MOQ?

A1 :MOQ may vary by customer's special requirement; we try our best to meet your business requirement.

Q2.Can you provide sample?

A2: Yes, we can offer sample , and some samples are free

Q3:Can you delivery by express?

A3: Yes, we can delivery by any express

Q4.Can you accept OEM ?

A4: YES! We can according your demand to produce.

Product Picture

Produce Processing

- Q: What are the production methods of calcium silicate board material?

- Calcium silicate (microporous calcium silicate) material and calcium silicate board are produced by static steaming method, dynamic hydrothermal synthesis method and two reaction method.

- Q: What kind of insulation material can withstand 350-600 degrees of high temperature?

- GB 50264-97 code for design of thermal insulation engineering for industrial equipment and pipelines98T901 cold storage Atlas of piping and equipment

- Q: Which is better, asbestos free calcium silicate and aluminium silicate refractory fiber?

- The two are thermal insulation materials. Calcium silicate board strength, cheap, but the use of temperature is not high, the highest 1000 degrees.

- Q: What is the difference between calcium silicate board and cement fiber board?

- How to distinguish fiber cement, pressure plate and calcium silicate board?1, calculate density: calcium silicate board density is much lower than the fiber cement pressure plate, through the weight of the plate can calculate its approximate density.2, look at the color: Although there are manufacturers in order to pretend to be fiber cement pressure plate and deliberately add carbon black and so on, the board made dark, but not natural cement color.3, ask whether there are super thin plate and super thick plate, if not or can not do, it means that he is selling calcium silicate board or ordinary fiber cement, non pressure plate.4, if you go to the factory, you can visit its workshop, if there is steam pressure (commonly known as bullets), it is certainly calcium silicate board manufacturers, if there is no press, it is a common cement plant.

- Q: Asbestos free calcium silicate board there is a crack in the kettle, what is the reason?

- Calcium silicate slab blank (blank off off phenomenon is not forming tube adhesion fingerboard blank above)There are two reasons: one is the blank off the vacuum negative pressure is too large, the blank water is too low, low viscosity; two is felt blocked, the billet made worse.The solution is to reduce the negative pressure, strengthen the cloth washing.

- Q: The ceiling of calcium silicate board and mineral wool board which is good

- The fire performance of third mineral wool board no calcium silicate board,Fourth mineral dampeasily yellow, moisture absorption is not good.The calcium silicate board will not have the above shortcomings, the thickness of 15mm if it is the calcium silicate board 4mm ceiling 600*600 thickness can reach the effect of the biggest advantages of mineral wool board, calcium silicate board also is not a burning fire, moisture absorption is very good, green building materials.

- Q: What are the new energy-saving building materials? What's new?

- As far as its varieties are concerned, the new wall materials mainly include bricks, blocks and slabs, such as clay hollow bricks, waste clay bricks, non clay bricks, building blocks, aerated concrete, light plates and composite boards.

- Q: What's the use of white portland cement?

- White portland cement as the raw meal with the proper components till the partial melting of the calcium silicate as the main ingredient, the iron content in clinker less addition of gypsum, white water ground made of rigid cementitious material. When grinding cement, allow limestone not to exceed 5% of the cement weight. White cement is mostly ornamental, and its manufacturing process is much better than ordinary cement. The gap is mainly used to hook white tiles, is generally not used in the wall, the reason is not high strength. It is available in the building materials market or decoration materials shop.

- Q: How to make building glue?

- An adhesive and a preparation method thereof, according to the proportion of the polyether and polyester resin, and multiple natural plant resin, polystyrene resin, solvent oil and ultraviolet resistant, anti-aging agent in the container, evenly stirring at 20 DEG -30 DEG C into TDI, heating up to 70 DEG -100 DEG 2-5 hours of stirring that uniform to room temperature, adding industrial gasoline diluted into oil, the transparent liquid is liquid, of course, according to the need of color, can also add to the metal paste color. The main feature of the invention is to glue sealing watering Ni bare surface, to set free, waterproof, anti cracking and water conservation effect, while the antirust effect is far more than the anti rust paint several times.

- Q: What is dew point of thermal insulation material?

- Thermal insulation materials are generally used to guide heat coefficient less than or equal to 0.2 of the material. Thermal insulation material development is very fast, and in industry and building the use of good insulation technology and materials, often can get twice the result with half the effort. Each ton of mineral cotton insulation used in the building saves one ton of oil a year.

Send your message to us

Calcium Silicate Board Better than Gypsum

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords