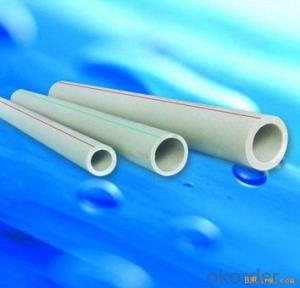

High-Quality Plastic Tubes - 2024 PPR Pipes for Industrial and Agricultural Fields

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Overview

1) Cold / hot water supply facilities for public buildings

2) Food, chemical, electronic industry pipeline networks; Such as Pipeline networks for transporting all kinds of corrosive liquids

3) Drinking water production system pipeline networks; Such as Pure water and mineral water

4) Air conditioning facility pipelines

5) Compressed gas pipeline networks for industry

6) Pipeline networks for swimming pools

7) Pipeline networks for solar energy facilities

8) Agriculture and garden production transporting systems

Why Us?

1.We can make any requirements in design, pattern, color and size.

2.We can make customer's logo on the surface of products.

3.The dimension tolerance of our products is controlled within 0.03mm.

4.Our products are child safety, pet safety and environment-friendly.

5.Our products are exported to America, Europe, India, west Asia, etc., and conforms to the standard test.

Our Services

1. OEM Manufacturing welcome: Product, Package...

2. Sample order

3. We will reply you for your inquiry in 24 hours.

4. after sending, we will track the products for you once every two days, until you get the products. When you got the

goods, test them, and give me a feedback.If you have any questions about the problem, contact with us, we will offer

the solve way for you.

Product Description

Pressure | Size(mm) | Pressure | Size(mm) |

PN1.25MPA | 20*2.0 |

PN1.6MPA | 20*2.3 |

25*2.3 | 25*2.8 | ||

32*2.9 | 32*3.6 | ||

40*3.7 | 40*4.5 | ||

50*4.6 | 50*5.6 | ||

63*5.8 | 63*7.1 | ||

75*6.8 | 75*8.4 | ||

90*8.2 | 90*10.1 | ||

110*10.0 | 110*12.3 |

Product Show

FAQ

Q1: How Can I Get A Sample?

A1: You can get samples by communicate with our export sales.

Q2: How Long Is Delivery?

A2: Delivery time will be30-45days according to order quantity.

Q3: What Is The MOQ?

A3: MOQ depends on different items.

Q4: What Is Our Normal Payments Terms?

A4: Our normal payment terms now is: T/T, L/C or western union, pay

- Q: 2001 mustang

- The person above me gave you some real good insight. The KN filter is your best bet. The plastic tubing you should be able to get at the same place you get your filter though. We have always gotten our stuff from there also.

- Q: one of the tubes from the radiator cracked so i want to glue them together..

- Sounds like a good plan if you want your car to overheat from lack of coolant. JBweld might do it but it costs more than just replacing the hose.

- Q: Is there an easy way to remember the color tubes (phlebotomy) and what test they are needed for?

- Phlebotomy Tubes Colors

- Q: Is rigid PVC double wall corrugated plastic pipe with HDEP pipe one kind?

- The materials used are different, the process and formula, and the processing temperature are different. The PVC formula has hundreds of thousands. Hope to adopt, thank you

- Q: Are plastic tubes suitable for packaging medical devices?

- Yes, plastic tubes are suitable for packaging medical devices due to their durability, flexibility, and ability to maintain product integrity. They provide protection against contamination, are easy to sterilize, and can be customized to meet specific requirements. Additionally, plastic tubes are lightweight, cost-effective, and offer excellent barrier properties, making them a preferred choice for packaging medical devices.

- Q: Can plastic tubes be used for DIY hydroponics systems?

- Yes, plastic tubes can be used for DIY hydroponics systems. They are commonly used as a cost-effective and versatile option for creating hydroponic systems. Plastic tubes can be easily customized and connected to create a network for nutrient solution delivery, allowing plants to grow in a soil-less environment.

- Q: Can plastic tubes be used for irrigation systems?

- Yes, plastic tubes can be used for irrigation systems. They are commonly used due to their durability, flexibility, and ability to resist corrosion. Plastic tubes are also cost-effective and easy to install, making them a popular choice for various irrigation applications.

- Q: Do plastic tubes have any limitations in terms of temperature resistance?

- Yes, plastic tubes do have limitations in terms of temperature resistance. While some types of plastic tubes can withstand high temperatures, such as those made from materials like polyimide or PTFE, most plastics have a limited range of temperature resistance. Exposing plastic tubes to temperatures beyond their specified limits can cause them to deform, melt, or become brittle, compromising their structural integrity and functionality. It is important to consider the intended application and select a plastic tube material that can withstand the expected temperature conditions.

- Q: Are plastic tubes suitable for vacuum applications?

- Plastic tubes can be suitable for vacuum applications depending on the specific requirements and conditions. Some plastic materials, such as PVC or polyethylene, may not be able to maintain a strong vacuum due to their inherent permeability to gases. However, other plastic materials, like nylon or PTFE, offer better resistance to gas permeation and can be used effectively in vacuum systems. Additionally, the design and construction of the plastic tube, including its wall thickness and reinforcement, play a crucial role in determining its suitability for vacuum applications. Ultimately, it is important to consider the specific needs of the vacuum system and consult with experts to select the most appropriate materials and design for the intended application.

- Q: What are the common applications of plastic tubes?

- Plastic tubes have a wide range of common applications, including packaging for products such as cosmetics, pharmaceuticals, and food items. They are also commonly used in plumbing systems for conveying fluids and gases. Additionally, plastic tubes are utilized in various industries for electrical insulation, cable management, and as structural components in construction projects.

Send your message to us

High-Quality Plastic Tubes - 2024 PPR Pipes for Industrial and Agricultural Fields

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords