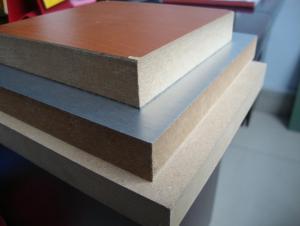

High Quality Melamine Faced Particle Board Subfloor for Furniture

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 500000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

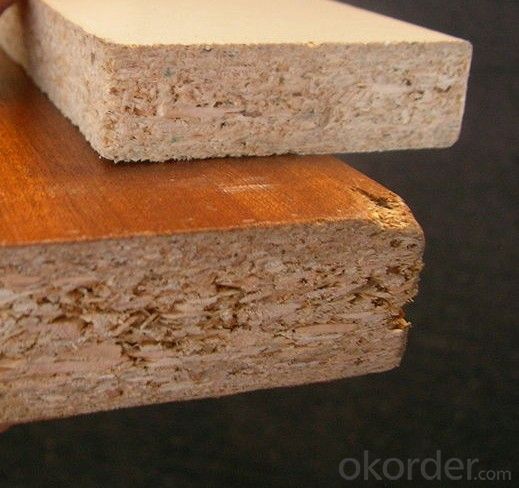

Name:particle boards

Size:1220*2440mm

Thickness:3-25mm

Glue:E0 E1 E2

Core:poplar hardwood combi

Production information

Size: | 1220*2440mm, 1250*2500mm, or as required |

Thickness | 9mm-25mm |

Gluing | E1, E2, E0 |

Material | wood chip, poplar, pine, birch, hardwood, combi |

Certifation | ISO9001,ISO1400,FSC,CE,CARB |

Moisture | 10-16% |

Diagonal tolerance | ≤+ 5mm |

Intensity | 0.35Mpa |

Formaldehyde emission | ≤30mg/100g |

Swell rate | <10%< span=""> |

Exterior structure intensity | ≥0.95Mpa |

Bending strength (kg/cm2) | 180,150 |

Density | 650-700kgs/cbm |

Payment terms | L/C at sight, T/T |

Delivery Time | within 15days after receiving deposit or original L/C |

Supply ability | 6000cbm/month |

Surface | plain or melamine, raw surface or laminated melamine paper |

Facing type | single-face, double-face |

Usage & Performance | Particle board is widely used for furniture, construction, decoration and packing |

Packing | Loose packing/ Standard export pallet packing |

Features

1) High bending strength

2) formaldehyde emission:E1 or E2

3) Strong nail holding

4) Moistureproof and easy work

5) Tight construction and high strength

FAQ

free samples are available

production time:20days after getting deposit

delivery time:30 days

payment term:T/T or L/C

- Q: What create an excellent condition.

- Many furniture manufacturers have re-use of particleboard as raw materials, in addition, directional particleboard is also gradually accepted by consumers

- Q: Today's demand for wood-based panel products

- coupled with the "Eleventh Five-Year" period of China's urban public facilities investment in fixed assets more than one trillion yuan

- Q: The Particleboard quality identification editor

- including North China, northwest, northeast plate moisture content is generally controlled at 6-8% is appropriate; the southern region,

- Q: What is the modeling technology department?

- mainly urea-formaldehyde resin, the product surface with a single board or resin impregnated paper paste, a molding.

- Q: The environmental performance of particleboard

- . It is a complicated process to detect the formaldehyde emission of particleboard.

- Q: Particleboard in the production process of environmental performance

- if the smell is large or have tears, indicating that the release of formaldehyde in the particleboard may be higher.

- Q: Market foreground and Industry development

- the quality of China's particleboard has been significantly improved, and re-accepted by the market,

- Q: According to the use of points: Class A particleboard; Class B particleboard

- According to the use of raw materials: wood particleboard; bagasseboard particleboard; linseed particle board; cotton stalk particle board; bamboo particle board; cement particle board; gypsum particleboard.

- Q: How to improve the particleboard market space

- In order to improve the quality of the particleboard and reduce the cost and improve the research and development capabilities

- Q: What are the disadvantages of particleboard?

- in the cutting board is likely to cause the phenomenon of violence teeth, so part of the process requirements for processing equipment higher; not on-site production;

Send your message to us

High Quality Melamine Faced Particle Board Subfloor for Furniture

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 500000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords