High Quality Glass Wool Roll for Thermal Insulation

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Glass wool blanket for thermal Insulation

1.Structure of Glass wool blanket for thermal Insulation:

Glass wool is an industrial product made by spinning glass into a fibrous material that can be packed in mats and blankets. This product is used as insulation and in other applications, like for air filters. It is available through home supply stores and manufacturers can also produce wools for special purposes, like insulation in aircraft, where the standards may be higher for health and safety reasons.Glass ool blanket with aluminum foil surface has good capability of heat radiatin protection.

2.Main Features of Glass wool blanket for thermal Insulation:

The glass wool blanket is applied for large laying area. In the field of insulation materials, we are mainly specializing in Glass wool products, including blankets, boards and pipes.These products have been widely used in heat preservation, thermal insulation and sound absorption in construction, chemical industry, electronic industry, electric power, metallurgy, energy industry, and communication. High density panels laminated with facing can be used for Air-conditioning duct system.

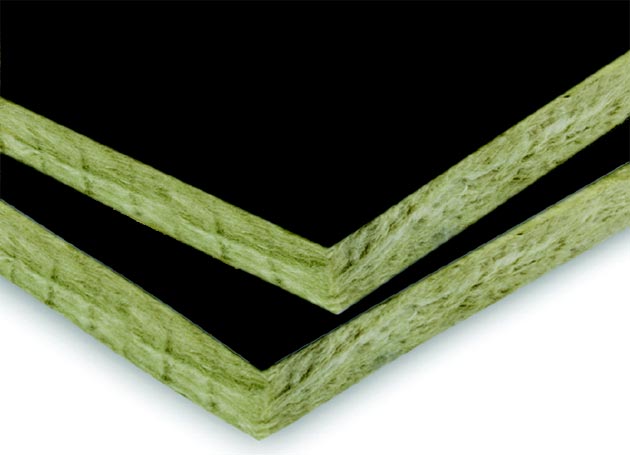

3. Glass wool blanket for thermal Insulation Images

4. Glass wool blanket for thermal Insulation Specification

The glass wool blanket is applied for large laying area. Besides the character of thermal insurance, it also has the performances of shock absorption and acoustical isolation, especially for middle or low frequency sound. It also can cancel the noise and improve working environment.

The glass wool blanket with aluminum foil surface has good capability of heat radiation protection.

The glass wool blanket with aluminum foil surface has good capability of heat radiation protection.

Technical Data

Item | Unit | Index |

Density | Kg/m3 | 10-32 |

Thickness | mm | 25-150 |

Width | mm | 600-1200 |

Length | mm | 10000-30000 |

Both unfaced and faced felts can be provided.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① Where you used this?

These products have been widely used in heat preservation, thermal insulation and sound absorption in construction, chemical industry, electronic industry, electric power, metallurgy, energy industry, and communication. High density panels laminated with facing can be used for Air-conditioning duct system.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: Are there any differences between glass wool and rock wool in terms of appearance, I can't distinguish them, why?

- They are completely different products, and put it in a simple way, glass wool is made of glass, rock wool is made of stone,

- Q: Are fireproof glass wool and centrifugal glass wool the same?

- It is not the same

- Q: How can I fix the glass cotton insulation board to the wall?

- If you have used composite boards as internal wall, you don't have to deal with the final layer engineering. Since composite boards are smooth both inside and outside, as well as flawless. If you really want to do the surface construction, you will use many materials. Because there are no composite boards with pure plane in the market, they all have grooves on the surface, and the grooves can increase the load bearing strength of composite boards. Supplement: That glass wool composite boards are fireproof?boards with metal surface. With rock wool and glass cotton as main materials, they use high-quality color coating steel plates as plane materials, continuous cotton fiber rock wool and glass wool as core materials, high-density rigid foam polyurethane as filling materials of tongue-and-groove. After high-pressure foaming and curing, automatic compacting, as well as ultra-long double caterpillar track controling, they take shape and become composite materials.

- Q: Glass wool can be used at zero degrees

- Ultra-fine cotton resin products, -120 ~ 400 ℃

- Q: What's wrong as the glass wool pipe is too soft?

- Two cases, one,thickness is too thin; two. Density is too light

- Q: What are the differences between the glass fiber and glass wool? ?

- Glass wool belongs to one of the glass fiber categories, which is a kind of man-made inorganic fiber. The sieve plate can not be replaced by glass fiber, which is a kind of elastic felty body produced by glass fiber whose diameter is only a few microns. Glass wool is a product made by fibering the molten glass and adding environmentally friendly recipe binder which is mainly thermosetting resin, use glass wool

- Q: what is the specification of glass wool sound-absorbing board?

- General specifications include 600 * 600600 * 500 * 1200-1200/12000300/400 mm thickness is usually 14 to 22 mm. . Glass wool belongs to a category of glass fiber, and is a kind of man-made inorganic fiber. Glass wool is a kind of spongiform material shaped by making melten glass fibering, it's chemical content belongs to glass and is a kind of inorganic fiber. It has good molding, small bulk density, low thermal conductivity, good thermal insulation and heat insulation, good sound absorption, corrosion resistance and stable chemical performance. Centrifugal glass wool belongs to porous materials and has good sound absorption performance. Centrifugal glass wool can sound-absorbing reason is not due to the rough surface, but because of there exist a large number of internal and external connected tiny pore and holes. When sound waves enter on the centrifugal glass wool, sound waves can follow the internal pore into inner material, cause the vibration of air molecules in space. Because of the friction of air viscous resistance and air molecules and pore wall, sound energy is wore down after being transferred into heat energy.

- Q: Glass wool products can be used for insulation layer

- Glass wool preservative

- Q: Is the centrifugal glass wool board suitable for home use?

- Is the centrifugal glass wool board suitable for home use?

- Q: What is the difference between high density glass wool board and stereoplasm rock wool board?

- The density (ie weight) of high-density rock wool board is large, but the hardness of it is not necessarily strong. The density of hard rock wool board is not necessarily high, but its hardness is very large, which is related to the fibre of rock wool, gel content and technical procedures.It is used in tanks with large plane and curvature radius, boilers, large steel structure and glass curtain wall.Attched with aluminium foil, it can better meet the requirement of heating air duct of air conditioning, insulating the cold water pipe and warm water pipe, block the moisture and insulating the building.When produced, marine and water-repellent wool insulation board is added with water-repellent additive enabling it to resist moisture.Rock wool board for boat is used for insulating heat and resisting fire for boats. Water-repellent wool board for thermal insulation in vehicles, mobile equipment, cold storage, air conditioning ducts and humid environment. It is also used in places that have certain requirements for moisture resistance.

Send your message to us

High Quality Glass Wool Roll for Thermal Insulation

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords